Electric injection molding for precision plastics

Ideal for precision molding, this electric injection system enhances efficiency with high-performance automation, ensuring consistent quality for complex multi-material and precision products.

Produces Precision Multi-Material Injection Molded Components

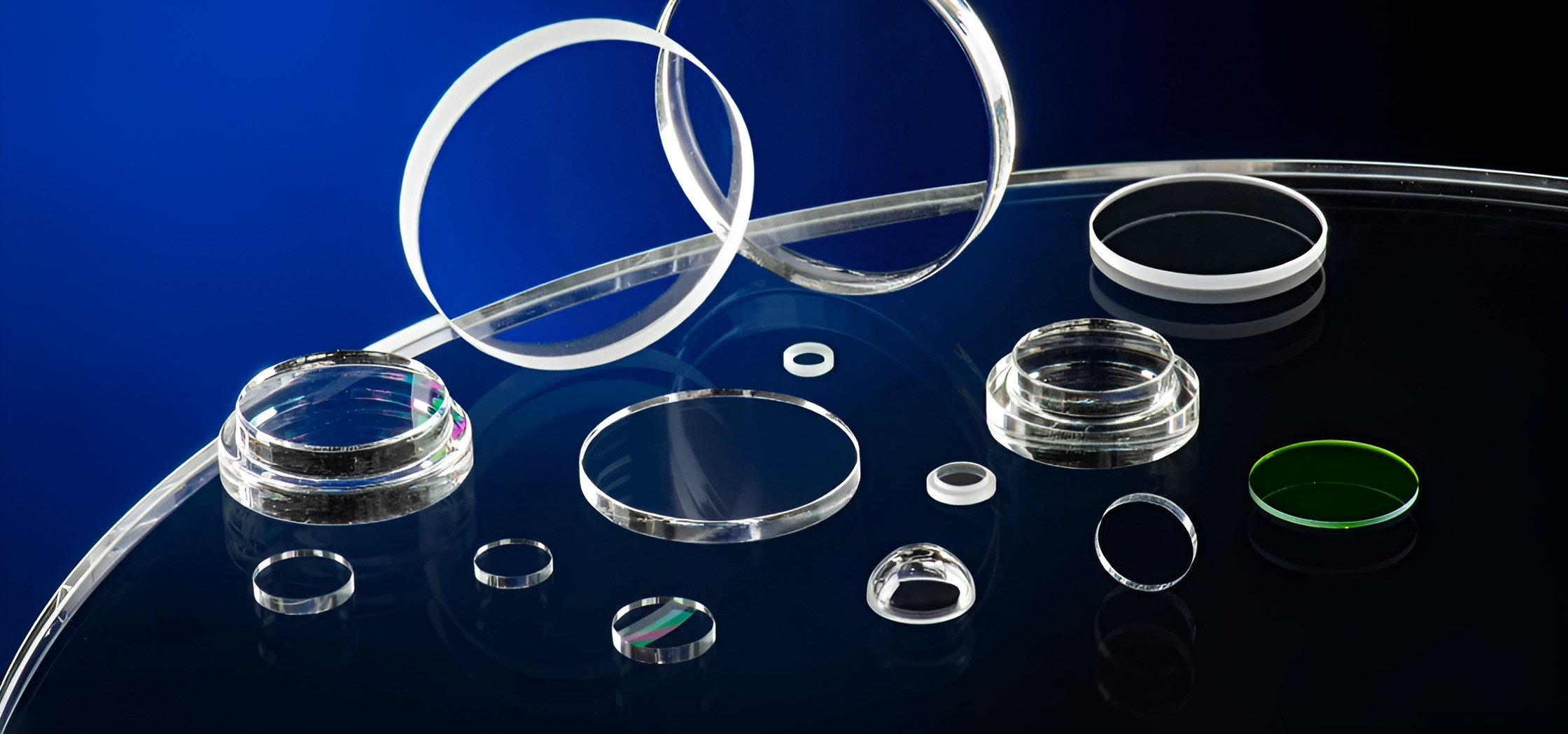

The FANUC ROBOSHOT series is a family of electric injection molding machines renowned for precision and versatility across multiple industries. Utilizing FANUC’s standard CNC control, these machines enhance precision and operational stability in injection molding processes, making them ideal for producing components like car interior panels and smartphone cases. Noteworthy for applications in automotive, consumer electronics, and medical device manufacturing, they offer superior integration with existing production lines, supporting high-volume, multi-material production with components such as optical lenses and kitchen utensils.

With automation and remote monitoring capabilities, the ROBOSHOT series ensures seamless operation and minimized downtime. Engineering is tailored to support high-productivity environments, with customizable options to fit specific manufacturing needs. ENERGY consumption is optimally managed, reducing overheads with variable-speed motor controls. In compliance with crucial industry standards and offering materials like stainless steel for enhanced durability, they stand out for their efficiency and reliability. Additionally, maintenance support features, including intuitive inspection tools, keep operations running smoothly without extended interruptions.

Benefits

- Enhances production efficiency with quick cycle times and high precision.

- Reduces operational costs through optimized energy management and automation.

- Facilitates complex, multi-material manufacturing to broaden product capabilities.

- Ensures compliance with industry standards, supporting regulatory alignment.

- Minimizes maintenance interruptions with integrated inspection support tools.

- Applications

- Medical devices, Household goods, Automotive components, Multi-material products, Plastic components, Fasteners, Consumer electronics, Industrial parts, Precision components, Packaging products

- End products

- Plastic bottles, Optical lenses, Syringes and medical tubing, Smartphone cases, Plastic housings, Bolts and screws, Car interior panels, Kitchen utensils, Machine gears, Overmolded electrical connectors

- Steps before

- Material Preparation, Mold Designing, CNC Programming

- Steps after

- Quality Inspection, Parts Assembly, Packaging

- Input ingredients

- Output ingredients

- Market info

- FANUC is renowned for its expertise in automation, specializing in manufacturing industrial robots, CNC systems, and machine tools, with a strong reputation for reliability and innovation in industrial automation solutions.

- Injection Type

- Electric

- Product Series

- ROBOSHOT α-SiA series / ROBOSHOT α-SiB series

- Performance

- High-precision

- Injection Molding Machine Models

- α-S30iB, α-S250iB, α-S300iB, α-S450iB

- Control System

- FANUC Standard CNC

- Injection Unit

- Second injection unit FANUC ROBOSHOT SI-A series

- Working Mechanism

- Electric Injection Molding

- Integrated Steps

- Precision Molding

- Operation Mode

- High-performance and High-reliability

- Automation Level

- CNC-Controlled

- Production Scale

- Larger Scale Molding Plant

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Machine series

- FANUC ROBOSHOT α-SiA / α-SiB

- Second injection unit

- Electric

- Control panel type

- FANUC standard CNC

- Injection molding type

- Electric

- Control panel type

- FANUC standard CNC

- Integration possibilities

- CNC, IoT

- Second injection unit

- Available

- Maintenance options

- Inspection support function