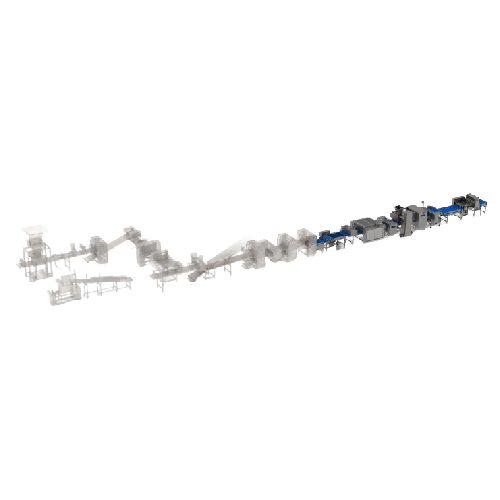

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of producing a wide array of croissant styles and flavors, enhancing throughput with precision and consistency.

Efficiently Produces Diverse Croissant Varieties

The Croissant Line from Rademaker is engineered to meet the demands of industrial and medium-scale bakeries, offering robust solutions for producing a diverse range of croissant varieties. This line stands out with its advanced integrated systems for dough processing, cutting, moulding, depositing, and baking. It supports processes for croissants, pastries, donuts, and more, seamlessly integrating into existing production facilities with ease.

Capable of handling capacities up to 240,000 pieces per hour, the line ensures high-speed, continuous operation with a focus on efficiency and yield. The automated control system allows for easy product changes and increased production flexibility, making it suitable for producing everything from classic croissants to specialty items like gluten-free or filled varieties. Additionally, the equipment’s hygienic design aids in quicker cleaning and maintenance, reducing downtime and operational costs.

Constructed with durable materials, the Croissant Line is available with features to optimize energy efficiency and support various product types, including solid and liquid fillings. It is equipped for compliance with industry standards, ensuring quality and safety in every batch. Tailored engineering support is available, allowing you to customize aspects like working width and filling systems to best fit your production line needs.

Benefits

- Increases production capacity to over 240,000 pieces per hour, maximizing throughput.

- Simplifies maintenance and reduces downtime with up to 50% faster cleaning and product changeover.

- Enhances production flexibility with diverse croissant shapes and fillings, meeting varied market demands.

- Improves operational efficiency with automated, continuous processing and ergonomic, lighter tooling.

- Ensures consistent product quality with precise cutting and moulding processes, reducing waste.

- Applications

- Pie, Buns, Bread, Flatbreads, Laminated dough, Pizza, Croissants, Quiche, Donuts, Pastries

- End products

- Italian style croissant, Rústico croissant, Filled croissant, C-shaped croissant, Spanish style croissant, Savory filled croissant, Pinched croissant, Straight croissant, Medialuna, Duo-color croissant, Mini croissant, Curved croissant, Gluten-free croissant, Long shelf-life croissant, Sweet filled croissant

- Steps before

- Dough preparation, Mixing, Laminating

- Steps after

- Proofing, Baking, Cooling, Filling (if applicable), Packing

- Input ingredients

- dough, fillings, raw croissant dough, semi-liquid fillings, solid fillings

- Output ingredients

- croissants, filled croissants, unfilled croissants, C-shaped croissants, pinched croissants, Rústico croissants, curvado croissants, mini croissants, long shelf-life croissants

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Hygienic Design Standard

- Highest hygiene standards

- Automation

- Fully automated

- Production Capacity

- Up to 240, 000 pcs./hour

- Production Variety

- Wide product variety

- Efficiency

- High efficiency and yields

- Working Widths

- 800 mm, 1, 000 mm, 1, 200 mm

- Capacity

- Up to 165, 000 croissants/hour

- Moulding Technology

- Consistent shaping

- Filling Capabilities

- Semi-liquid, solid, double

- Cleaning Time Reduction

- Up to 50% easier and faster

- Durability

- Extremely robust and durable

- Stroke Rate

- Up to 200 strokes/minute

- Automation level

- Fully automated

- Efficiency

- High production capacity

- Hygiene standards

- Highest hygiene standards

- Product changeover

- Up to 50% faster

- Strokes per minute

- Up to 200 strokes per minute

- Lamination width

- 800 mm / 1, 000 mm / 1, 200 mm / 1, 400 mm

- Cleanability

- High hygiene standards

- Machine footprint

- Customizable

- Working width

- 800 mm, 1, 000 mm, 1, 200 mm, 1, 400 mm

- Shape and size

- Various shapes and sizes of croissants

- Discharge method

- Fully automated

- Working Widths

- 800 mm | 1, 000 mm | 1, 200 mm | 1, 400 mm

- Shape Variety

- Straight, bent, filled, small or big croissants

- Filling Types

- Sweet, savory, semi-liquid, solid, double fillings

- Production Configurations

- Medium to full industrial scale

- Automation Level

- Fully automated lines