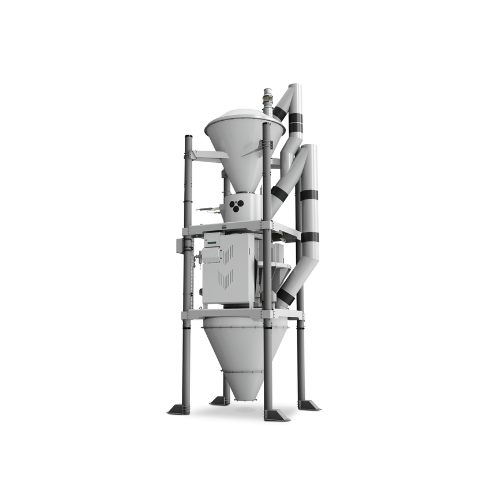

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and granular materials, ensuring optimal product compositions and process stability in demanding production environments.

Ensures Precise Dosing and Consistent Material Flow

The MSDM, MSDC, MZAL, MSDH, and MSDI from Bühler are fully automatic loss-in-weight scales designed specifically for accurate dosing of both powdery and granular products. These machines are integral to achieving high precision in industries such as food, feed, cosmetics, and advanced materials by ensuring consistent material flow and optimal product composition. With capacities ranging up to 360 m³/h and high repeatable accuracy down to ±0.1%, these scales are ideal for applications including animal and aqua feed, bakery goods, and chemical processing. Their mild steel platforms provide robust operation and high safety standards for food applications. The scales are engineered for easy integration with PLC control systems, enabling seamless addition to existing production lines and offering energy efficiency improvements due to their optimized dosing processes. Bühler offers customization options to align with specific process requirements, along with comprehensive engineering support to facilitate installation and maintenance.

Benefits

- Enhances production accuracy with consistent dosing precision of down to ±0.1%.

- Integrates seamlessly into existing lines, reducing setup time and increasing productivity.

- Conserves resources by minimizing material waste through precise material handling.

- Ensures operational safety with robust mild steel construction.

- Supports a wide range of industries, increasing versatility and potential applications.

- Applications

- Snacks, Grain, Cosmetics, Chocolate, Dairy, Chemicals, Asian noodles, Biorefinery, Printing inks, Pulses, Paddy, Spices, Aqua feed, Biomass, Breakfast cereals, Batteries, Cocoa, Animal feed, Pasta, Pet food, Nuts, Rice, Paints, Dried fruits, Electronic materials, Baked goods, Insect technology, Oilseeds, Wheat, Confectionery, Coffee, Digital inks, Coatings, Vegetables

- End products

- Spaghetti, Whole wheat flour, Lithium-ion batteries, Potato chips, Candy bars, Espresso beans, Brown rice, Cattle feed, Wall paint, Jasmine rice, Turmeric powder, Fragrances, Bread flour, Fish pellets, Croissants, Inkjet printer ink, Semiconductor wafers, Cricket flour, Dehydrated carrots, Biodiesel, Flexographic printing ink, Cornflakes, Lentil flour, Cat kibble, Almonds, Instant noodles, Ethanol, Sunflower oil, Chocolate bars, Pasteurized milk, Raisins, Lipstick

- Steps before

- Milling, Grinding, Flaking, Dehulling, Conditioning, Cooling, Buffering

- Steps after

- Optical sorting, Packing, Palletizing, Sifting, Grading, Roasting

- Input ingredients

- powdery materials, granular products, powdery additive products, premixes

- Output ingredients

- processed products, product compositions, blending sections

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Accuracy

- ± 0.1%

- Accuracy

- ± 0.2%

- Accuracy

- ± 1%

- Capacity

- Up to 360 m³/h

- Capacity

- Up to 240 dm³/h

- Capacity

- Up to 133 m³/h

- Capacity

- Up to 107 m³/h

- Capacity

- Up to 90 m³/h

- Automation

- Fully automatic

- Material Type

- Powdery and granular products

- Material Type

- Granular materials and products

- Material Type

- Powdery additive products and premixes

- Working mechanism

- Automatic batch scale

- Automation level

- Fully automatic

- Integrated steps

- Weighing and dosing

- Batch vs. continuous operation

- Batch / Continuous

- Space-limited solutions

- Compact design

- Energy efficiency

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Platform material

- Mild steel

- Discharge method

- Automatic

- Control panel type

- Automatic

- Control panel type

- PLC interface

- Integration possibilities

- SCADA compatibility

- Material of construction

- Mild steel

- Dosing type

- Fully automatic

- Capacity customization

- 12 to 360 m3/h

- Product type compatibility

- Powdery and granular

- Batch vs. continuous capability

- Continuous dosing

- Compact solution

- Space-limited design