Find innovative biomass equipment and connect directly with world-leading technology suppliers

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Stories about biomass

Select your biomass process

Tell us about your production challenge

Which biomass technology do you need?

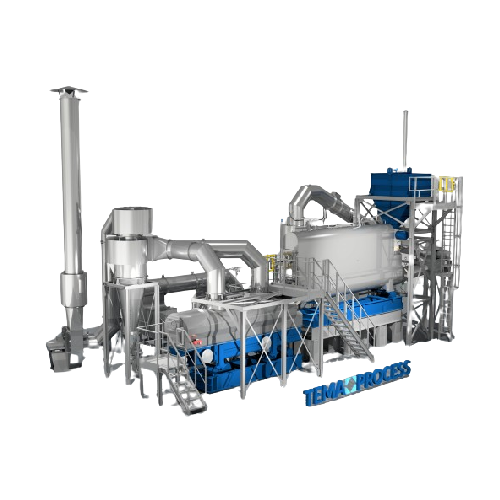

Efficient biomass screw dryers

Optimize biomass processing with screw drying technology that efficiently reduces moisture co...

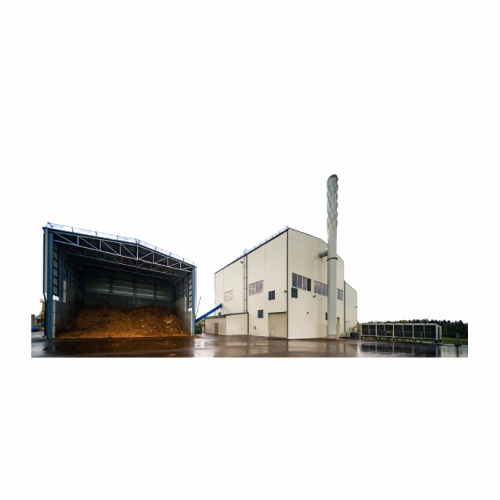

Biomass-fired heat and power plants for industrial applications

Achieve efficient thermal and electrical energy producti...

Industrial biomass hot water boiler

Ensure reliable and sustainable hot water generation for high-demand heating and indust...

Downdraft dryer for biomass drying

Quickly reduce moisture content and energy consumption with a versatile dryer that reloc...

Biomass baler for woody biomass collection

Optimize woody biomass management with a mobile solution that reduces noise, du...

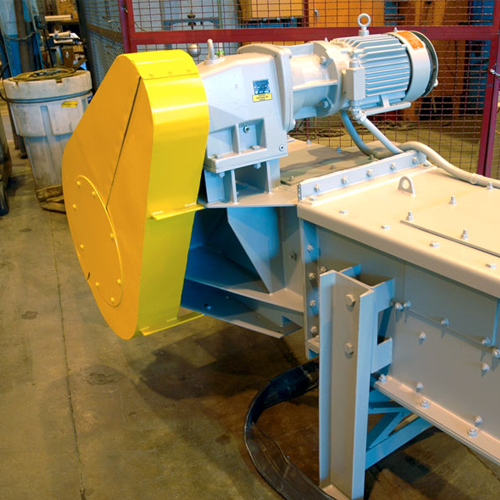

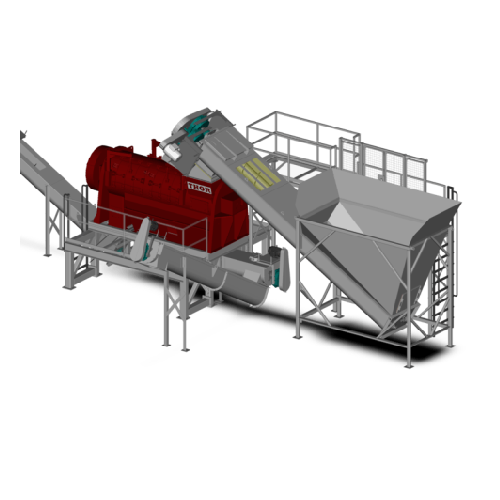

Rotary shear for wood chips and biomass processing

Efficiently transform diverse biomass materials into uniform particles...

Pilot-scale commercial rotary shear for biomass processing

Optimize your biomass processing with efficient particle size...

Precision feedstocks for biomass energy production

Optimize your biomass conversion with precision-sized feedstocks desig...

Cubic triaxial tester for biomass flowability

Ensure the smooth flow of chipped and ground biomass with precise material f...

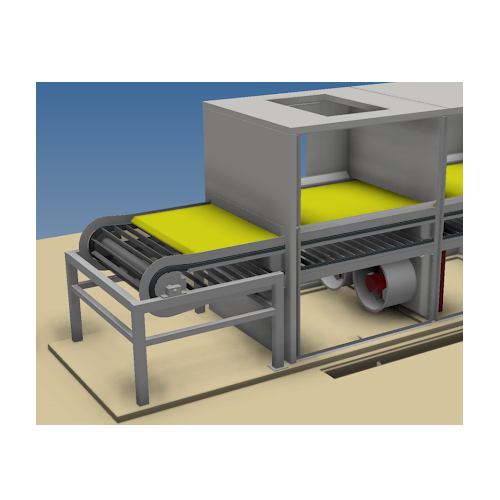

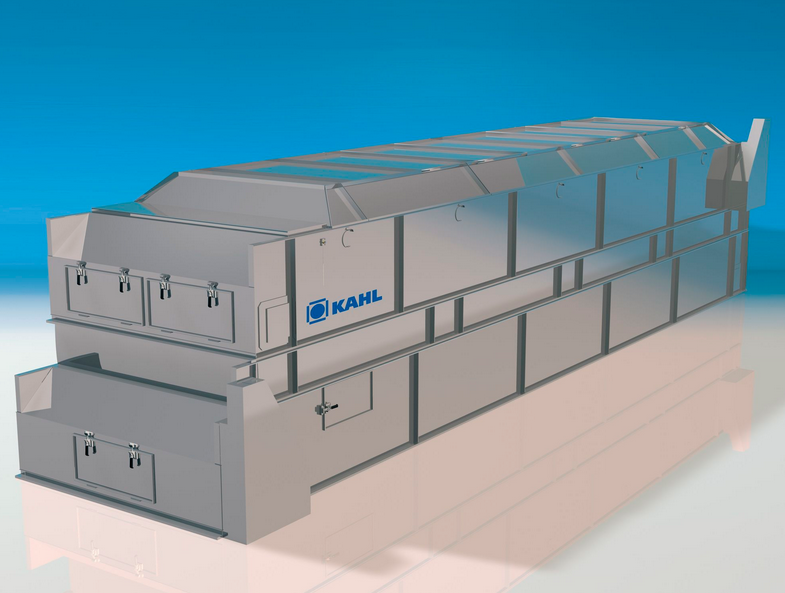

Advanced downdraft conveyor dryer for biomass feedstocks

Achieve precise moisture control and energy efficiency with adva...

Pyrolysis for biomass conversion

Transform diverse waste materials into valuable bio-commodities and energy through advanced...

High-speed centrifuge for biomass and particle harvesting

Achieve high-speed particle separation and biomass harvesting ...

Ashing furnace for biomass with afterburner

Efficiently process high-smoke materials like biomass through advanced afterbu...

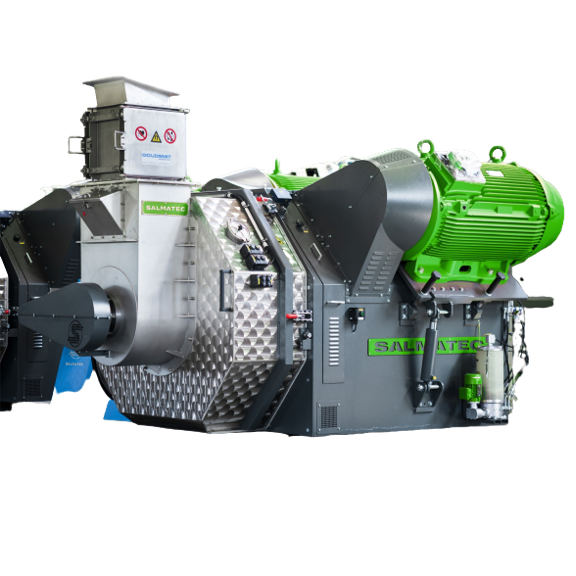

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied mater...

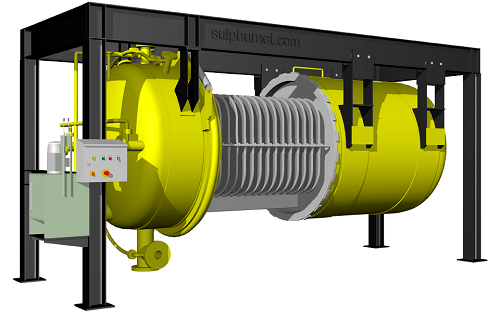

Biomass drying solution

Achieve efficient and gentle biomass drying with innovative heat exchange technology, ensuring optima...

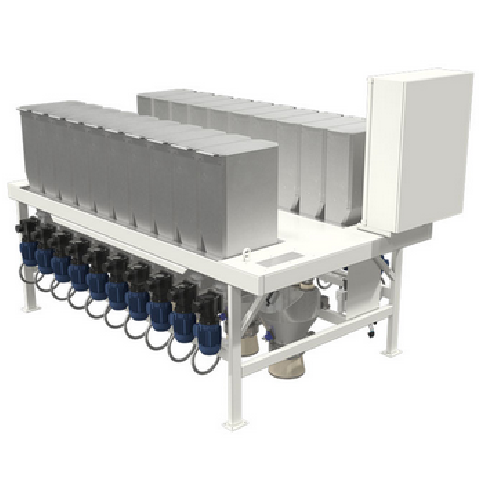

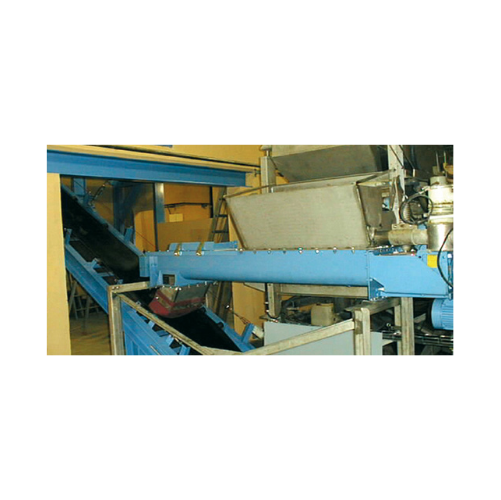

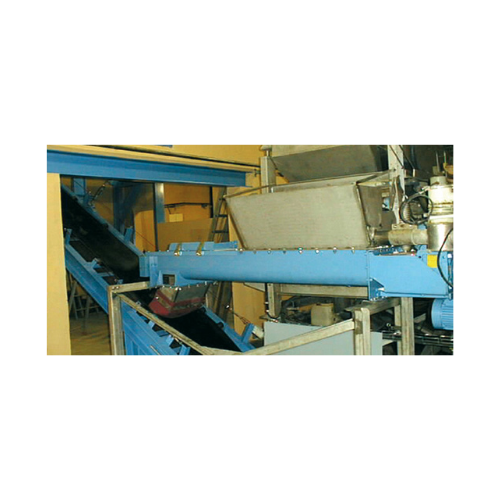

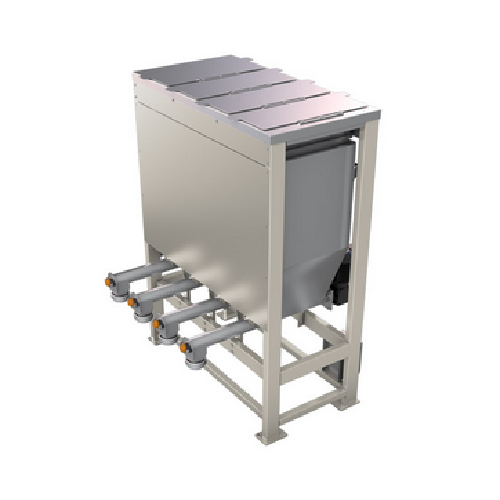

Biomass digester feeding system

Efficiently integrate biomass into your biogas production process with a system that seamles...

Bulk biomass digester feeding system

Optimize your biogas production with a versatile system designed for efficient biomass...

Mobile belt dryer for sawdust and biomass

Efficiently reduce moisture in a variety of materials, from sawdust to cereal sn...

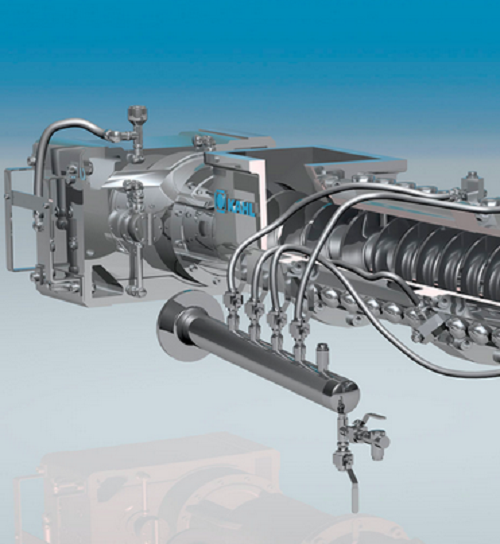

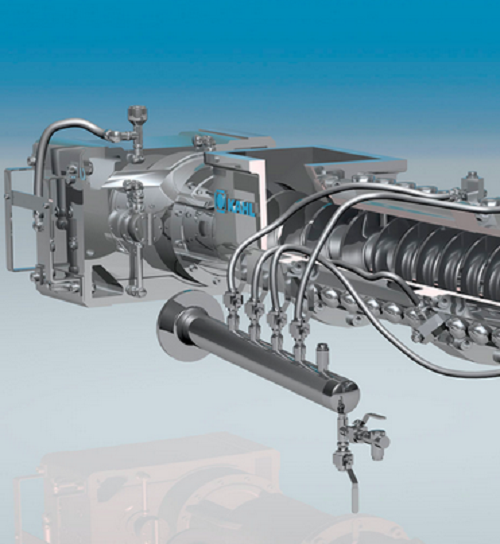

Dewatering press for rubber, sugarcane, and biomass

Optimize your production line with a compact, energy-efficient soluti...

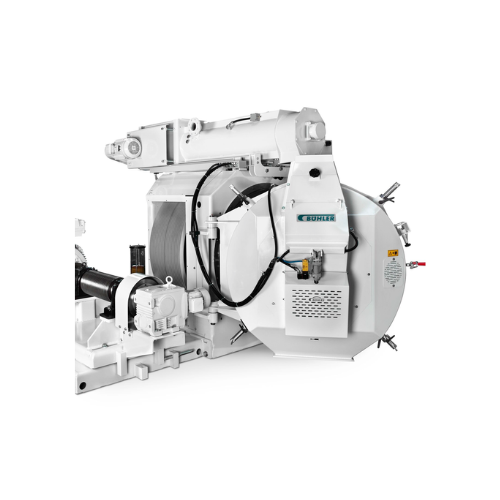

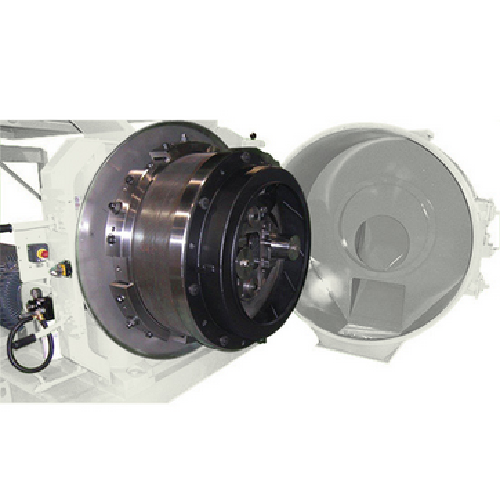

Pelleting press for biomass

Utilization of biomass for energy and other applications requires consistent and reliable compac...

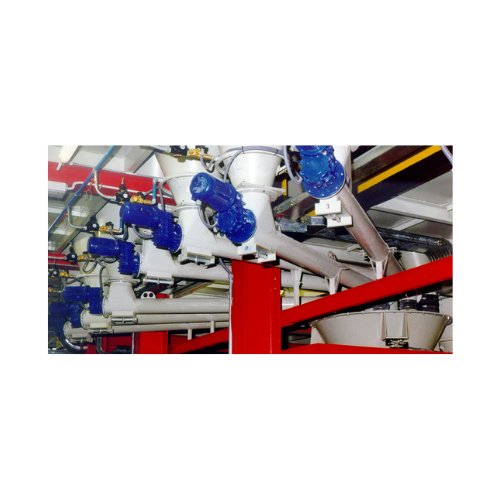

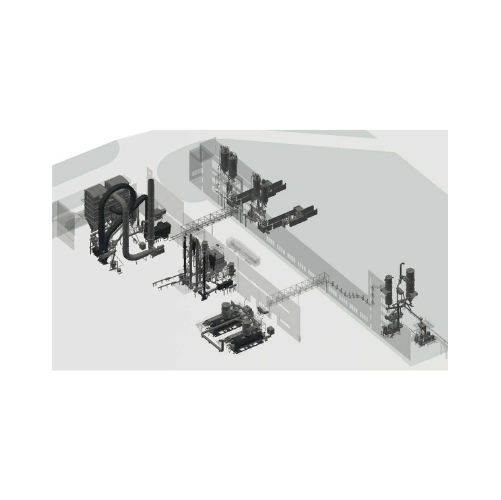

Pneumatic conveying for industrial biomass boilers

Modern boiler plants have a wide variety of conveying needs. While tr...

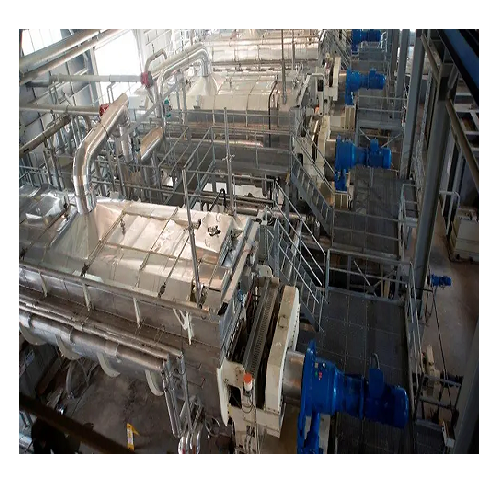

Solid biomass boiler feeding systems

Energy conversion from biomass requires efficient boiler operation which is largely in...

Ash handling systems for industrial biomass boilers

The increasing use of solid fuels including biomass for energy conver...

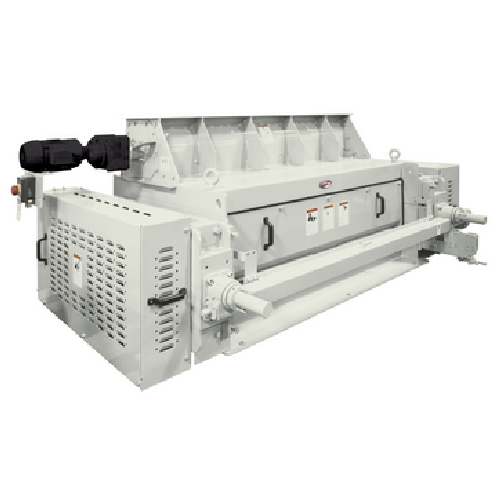

Solid biomass screening and crushing equipment

Biomass fuels come in many forms and often include impurities that can dama...

Solid biomass receiving systems

Biomass fuels come in many forms and are often handled in very large quantities. Shipment m...

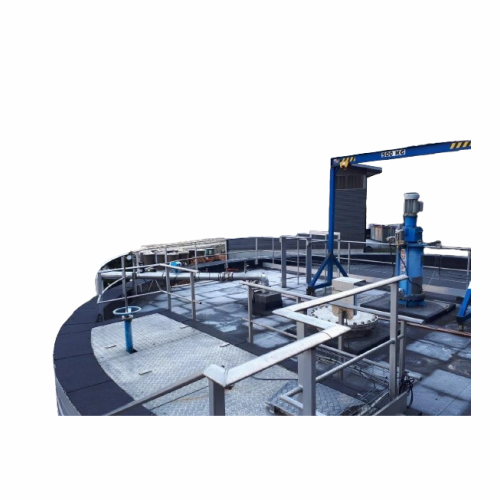

Solid biomass storage and reclaiming equipment

Biomass fuels must often be stored for additional preprocessing or prior to...

Screw press for mechanical oil extraction

Maximize protein extraction and oil yield with precision screw presses designed ...

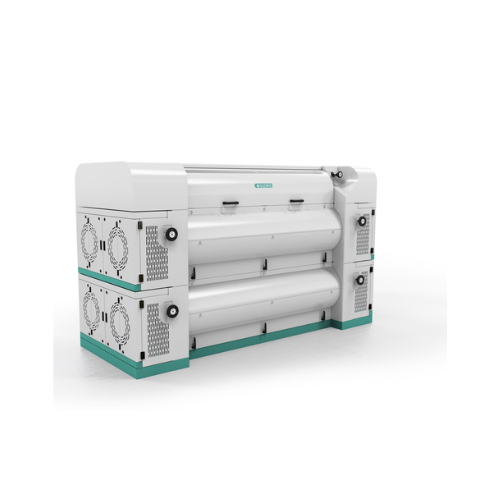

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

Unloader for non-free-flowing materials in flat bottom silos

Facing challenges unloading non-free-flowing materials? Thi...

Industrial carbon capture system for flue gas

Capture and transform combustion flue gas into valuable CO2 outputs with our...

Industrial water tube steam boilers

Optimize energy efficiency and reduce fossil fuel reliance with high-performance steam ...

Agitator for biogas digesters in anaerobic digestion

Achieve efficient anaerobic digestion and optimal biogas recovery by...

Orbital screen for precise feedstock sizing

Achieve precise particle sizing and separation with this compact orbital scree...

Replacement parts for rotary shear systems

Optimize your biomass processing with durable rotary shear systems, ensuring ef...

Downdraft conveyor dryer for industrial drying applications

Achieve consistent drying with reduced energy consumption us...

Crumbler for research and lab use

Achieve precise size reduction and particle formation for diverse materials in lab settin...

Screw heat exchanger for efficient thermal processing

Optimize your heating and cooling processes with this robust double...

Bulk packaging solution for biochar

Protect biochar from rapid oxidation and ignition with a vacuum-sealed, nitrogen-purged...

High-speed centrifuge for laboratory applications

Maximize efficiency in high-volume centrifugation tasks with this versa...

Microalgae photobioreactors for bioenergy production

Optimize your microalgae’s growth and conversion processes wit...

Carbon and sulfur analyzer for organic and inorganic samples

Achieve precise and simultaneous carbon and sulfur analysis...

Industrial roller mill for grain size reduction

Achieve precise grain size reduction with minimal heat generation and opti...

Accurate weighing system for micro ingredients

Ensure precise micro-ingredient dosing for batch operations with this versa...

High-capacity ring-die pellet mill for animal feed production

Optimize your high-capacity feed production with this pell...

Laboratory pellet press for testing and formulation

Achieve precise pellet formulation and performance testing with versa...

Pellet mill for noise-reduced pelleting

Optimize production with a pellet mill designed to minimize noise and enhance lubri...

Roller mills for high-demand crushing applications

Optimize your production line with versatile roller mills designed to ...

Efficient barley malt crushing with roller mills

Achieve precise particle size control in your processing line with a robu...

Industrial roller mill for barley malt crushing

Ensure precise barley malt crushing with minimized maintenance for enhance...

Steam chambers for grain expansion in steam-flaking

Ensure precise grain expansion with steam chambers, designed for unif...

Bulk bag weighing system for batching operations

Streamline your batching process by accurately weighing minor ingredients...

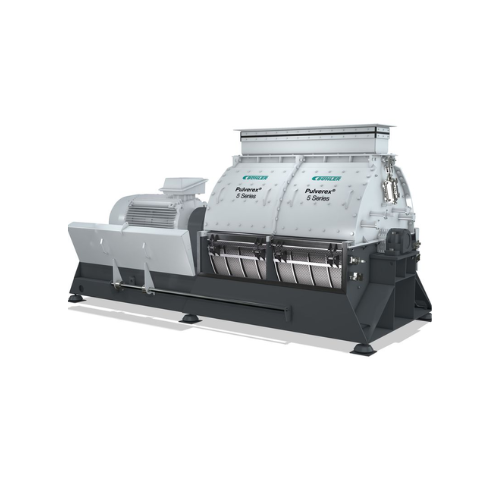

Industrial hammermill for size reduction

Optimize your production line with high-efficiency size reduction, designed to han...

Industrial lump breaker for particle size reduction

Optimize your production line with an advanced solution for efficient...

Heavy-duty crusher for 6-inch material

Efficiently tackle challenging crushing tasks with our solution designed to process ...

Industrial shredder for high-capacity shredding and delumping

Optimize production with precision shredding and delumping...

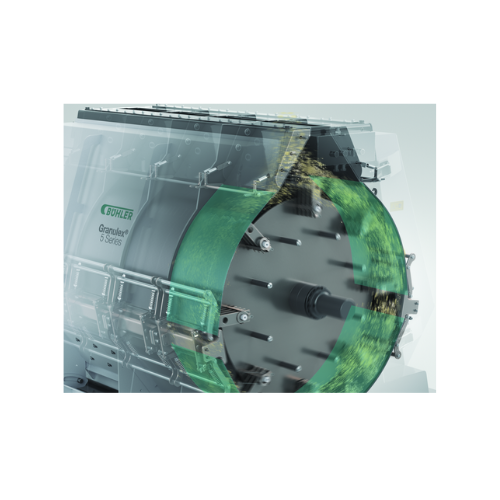

High-capacity pellet crumbler

Achieve precise pellet size reduction with this high-capacity solution, designed for effortles...

Pellet crumbler for animal feed pelleting

Optimize pellet size reduction with precise control and high efficiency, ensurin...

Small-scale pellet mill for animal feed production

Achieve precise pellet formulation for diverse feedstocks with an effi...

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

High-capacity pelletizer for oilseed meal processing

Maximize throughput and ensure consistency in your pelleting process...

Industrial feed conditioner for optimal moisture absorption

Achieve precise control of moisture and temperature to enhan...

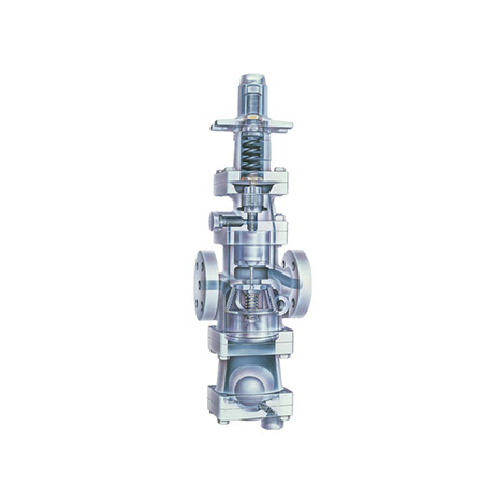

Industrial steam systems for conditioning

Efficiently deliver optimal steam conditioning for diverse feedstock, enhancing ...

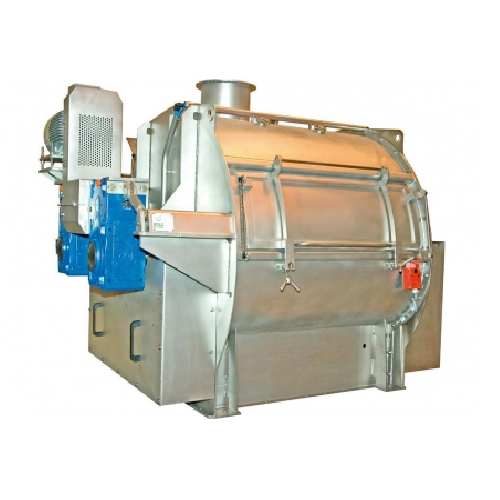

Heavy-duty horizontal dryer/cooler for pellets and meal

Optimize your production line with continuous high-speed drying a...

Industrial circular coolers for uniform product cooling

Achieve consistent cooling across your product range with circula...

Oilseed cracking solution

Maximize throughput with precision cracking, ensuring optimal downstream processing for oilseed pr...

Oilseed cracking mill for efficient processing

Designed for high-capacity oilseed processing, this cracking mill enhances ...

Gyro sifter for feed cleaning

Eliminate contamination and optimize product quality with high-speed screening and cleaning te...

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

Coal ash fusibility furnace for laboratory testing

Ensure precise ash fusion temperature analysis for coal, biomass, and ...

Vertical hammer mill for feed and grain processing

Optimize your milling operations and improve energy efficiency with th...

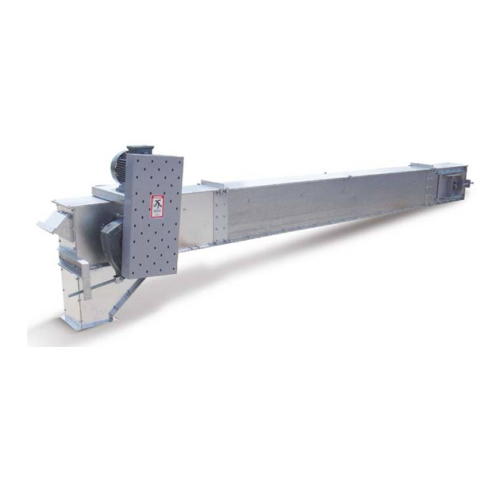

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

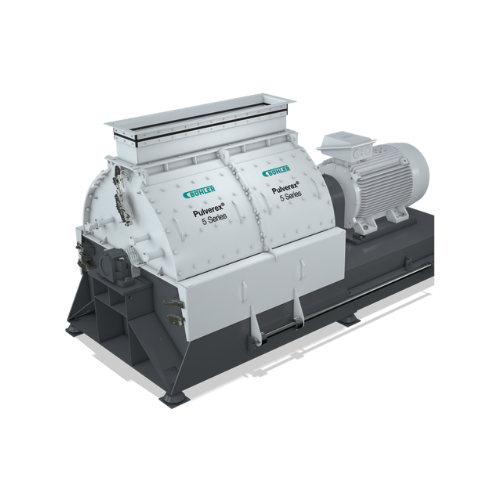

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Hammer mill for size reduction in food and feed processing

Efficiently tackle size reduction challenges with a versatile...

Hammer mill for animal feed grinding

Achieve precise granulation with high throughput and energy efficiency, while reducing...

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced pad...

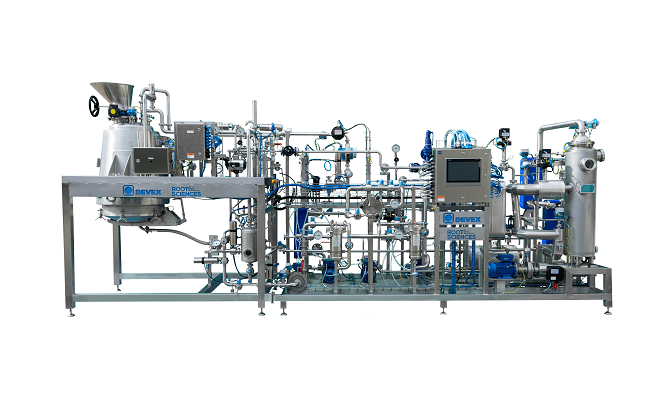

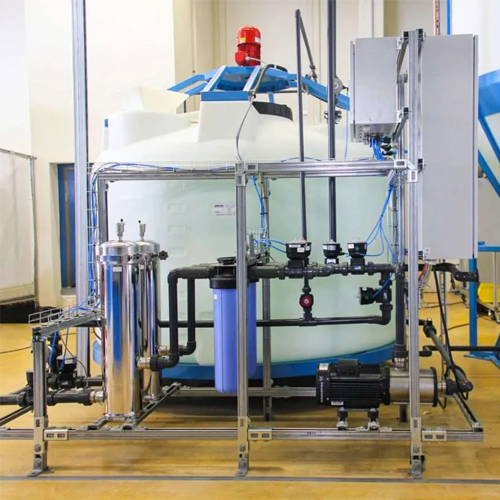

Ice water extraction system for solventless extract production

Optimize your plant-based extraction processes with a mod...

Biogas plant screw press separators

Maximize your renewable energy output and processing efficiency with cutting-edge solid...

Tubular screw conveyor for concrete production

Optimize your production line with a versatile solution designed for effici...

Horizontal screw press separator for biogas plants

Enhance biogas production efficiency by effectively separating high-mo...

Horizontal screw press separator for pomace yield optimization

Enhance your production line by efficiently separating so...

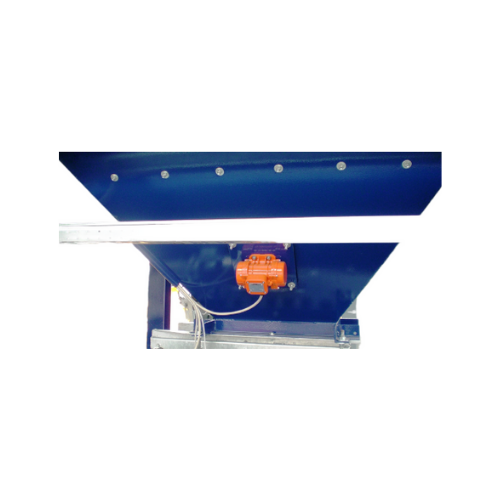

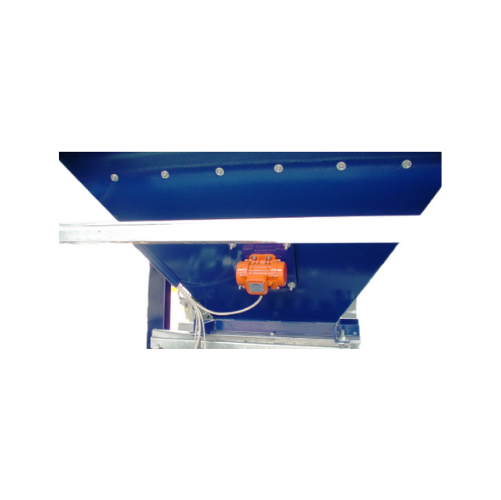

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for hazardous materials

Ensure safety and efficiency in hazardous environments with relia...

Continuous twin shaft paddle mixers for dust conditioning

Optimize your mixing process with twin shaft paddle mixers, en...

Continuous twin shaft paddle mixers for sludge conditioning

Optimize your sludge and waste treatment processes with a co...

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this be...

Industrial dust collection system

Optimize your process by efficiently capturing and removing airborne dust particles, ensu...

Continuous bulk fluid bed dryer

Achieve rapid and energy-efficient moisture removal across diverse materials with our advanc...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

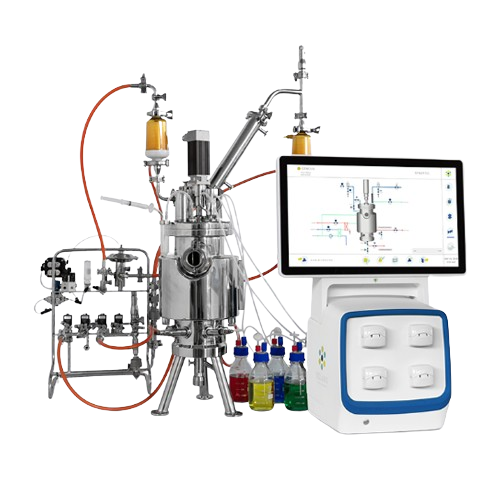

Lab-scale microalgae cultivation system

Achieve precise control of microalgae cultivation with optimized growth conditions ...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Stationary grain dryer with biturbo system

Optimize your drying processes with a system that efficiently manages air flow ...

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

3d screening solution for recycling facilities

For facilities handling diverse recycling materials, a solution that effect...

Pelletizer for chaff

Transform chaff and agricultural byproducts into valuable energy pellets with precision and efficiency, ...

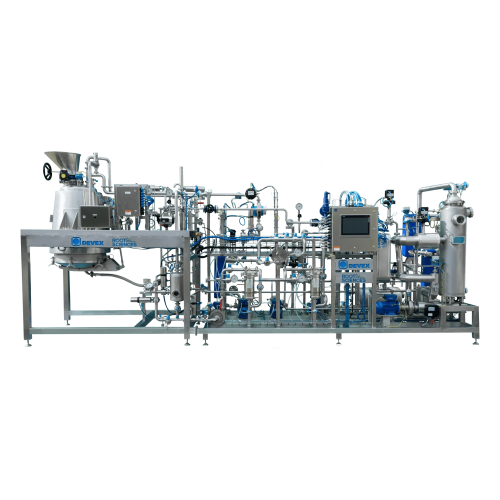

Edible oil processing solution

Optimize your production line with advanced pressing and dewatering technology, ensuring high...

Degumming plant for edible oil refining

Achieve optimal purity and quality in edible oils through precise degumming process...

Crane scales for precise weighing in chassis

Optimize space with low-profile crane scales, ensuring accurate weight measur...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Coal pulverization grinding mill

Maximize efficiency in pulverizing coal with continuous operation and low maintenance, idea...

Solids flow meter for bulk solid streams

Ensure precise bulk material measurement with a system designed for accuracy and r...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in de...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Energy saving vertical steam dryer for paper pulp

Apart from soil and water pollution with cholates, chlorine, and metal ...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

Exergy pressurized superheated steam dryer

Traditional dryers and heat transfer systems, like belt-, drum- or bed dryers a...

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

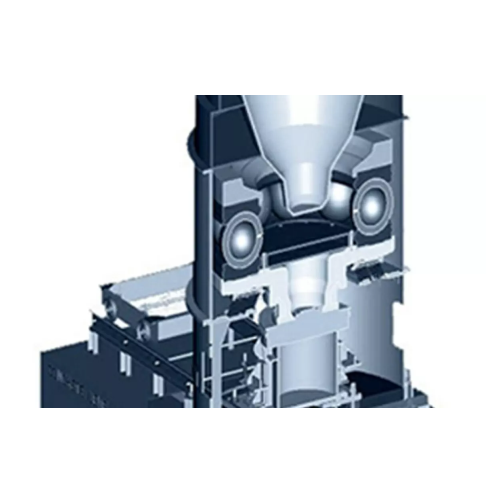

Wood chip gas syngas generator

The recovery of energy from biomass isn’t all advantages, it has its shortcomings as well. Bi...

Automatic centrifuge for cannabis

Centrifugation is an effective method for producing cannabis extracts. The extraction pro...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

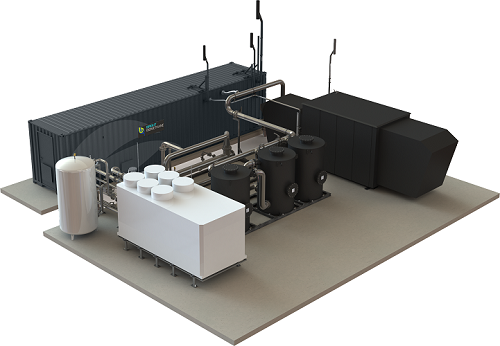

Efficient sized biomethane production system

Also referred to as biogas purification, biogas upgrading is an excellent alt...

Belt dryer for digestate

The drying of poultry manure digestate requires careful and consistent moisture level control. A sus...

H2S scrubber for biogas

Raw biogas produced by digestion, for example during an anaerobic process is approximately 60% methan...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Additive and bed material feeding systems

Modern fluidized bed combustion furnaces require consistent and reliable deliver...

Belt dryer for wood

Processing of wood and biomass into pellets or other volume reduced products requires careful and consist...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Industrial pre-cleaners for raw material safeguarding

Effectively eliminate foreign objects from your raw materials with ...

Cone calorimeter for fire testing and safety engineering

Ensure safety in your materials by precisely measuring combustio...

Guarded hot plate for thermal conductivity testing

Ensure optimal insulation performance with precise thermal conductivit...

Silo unloader for difficult products

Tackle challenging silo extractions with a robust unloading system designed for high-s...

On-line particle size and shape analyzer for industrial processes

Optimize your production line with precise, real-time...

Gas contactor for hydrogen sulfide removal from biogas and sour gas

Efficiently convert harmful hydrogen sulfide into m...

Manure biogas plant for agricultural sector

Transform animal waste into renewable energy and nutrient-rich bio-fertilizer,...

Organic residue and manure biogas plant

Transform organic waste into renewable energy while efficiently reducing carbon emi...

Biogas upgrader for high methane yield

Optimize biogas production by efficiently converting raw biogas into high-purity bio...

Fermentation monitor for alcohol production

Optimize anaerobic yeast fermentations with precise monitoring of carbon conve...

Pneumatic truck unloading for bulk tankers

Efficiently unload bulk materials from trucks with minimal dust emissions while...

Air pelletizer for wood and natural fiber compounds

Optimize your pelletizing process with air-based cooling and conveyin...

Organic rankine cycle for decentralized power generation

Harness waste heat and renewable energy sources to efficiently g...

Industrial ring dryers for high-capacity drying applications

Maximize drying efficiency for diverse materials with ring ...

Heavy-duty roll crushers for crushing applications

Optimize your crushing and grinding processes with robust roll crusher...

Loss-in-weight scale for micro ingredient batching

Enhance precision in your production line with advanced micro ingredie...

Industrial crusher for medium- to heavy-duty applications

Enhance efficiency in material size reduction operations with ...

Industrial grain flaking solution

Enhance grain processing efficiency with precision-engineered flaking solutions, designed...

Oilseed flaking mill

Enhance flake consistency and output efficiency with advanced roll technology designed to optimize your ...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

High-temperature Tf tube furnace

Optimize your thermal processing with versatile tube furnaces designed for precise heat tre...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

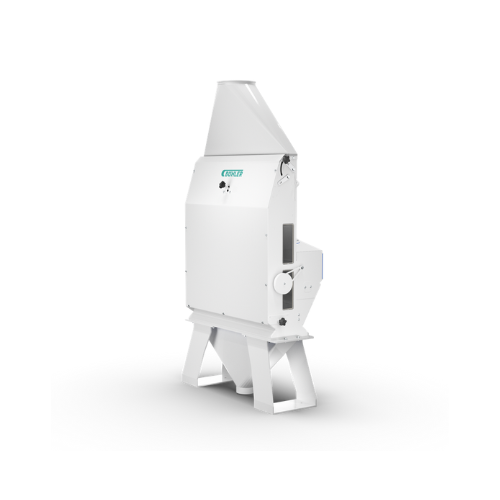

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Carbon capture membranes for Co2 separation

Efficiently reduce carbon emissions in power plants and industrial operations ...

Cross flow filtration for industrial liquid purification

Optimize your production process with advanced cross flow filtra...

Plate surface condenser for vapour under vacuum

Experience high-efficiency condensation in space-constrained environments ...

Heat exchanger for fibrous and coarse particle fluids

For operations involving fibrous and coarse particle fluids, this a...

Heavy duty granulator for high-capacity size reduction

When tackling high-volume materials, rely on these industrial-grad...

High-temperature tube furnace for laboratory applications

Achieve precise thermal treatment with this high-temperature t...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Jet scrubber for industrial gas cleaning

Efficiently manage gas emissions and hazardous particles in high-demand operations...

Industrial rotary dryer for high moisture content materials

Achieve consistent drying performance with industrial rotary...

Decanter centrifuge for bioethanol production

Optimize bioethanol production with enhanced separation efficiency, enabling...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Continuous single shaft mixer for waste treatment

Achieve consistent mixing homogeneity and prevent dead spots in your pr...

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

Heavy-duty submersible chopper pumps for manure treatment

Optimize your wastewater and manure handling with submersible ...

Pulp and paper horizontal screw press separator

Optimize your pulp recycling and manure treatment with high-efficiency sol...

Tapioca waste fibrous slurry separator

Effectively manage fibrous slurry and optimize your waste streams with a high-perfor...

Tapioca horizontal screw press separator for wastewater treatment

Optimize your waste management with advanced solids-l...

Tapioca horizontal screw press separator for biogas plants

Achieve high-efficiency separation and compaction of diverse ...

Biogas digestate screw press separator

Achieve efficient solids-liquid separation in biogas and wastewater treatment proces...

Horizontal screw press separator for biogas digestate treatment

Optimize your biogas plant’s efficiency by effecti...

Screw press separator for biogas digestate treatment

Optimize your biogas plant’s efficiency with a robust solution...

Cow manure screw press separator

Enhance nutrient recovery and reduce waste management costs with our robust screw press sep...

Horizontal screw press separator for sludge and manure

Achieve high-efficiency separation of solids and liquids from dive...

Horizontal screw press separators for biogas plants

Achieve efficient solids-liquid separation with continuous operation,...

Air cannons for resolving bulk material flow issues

Solve bridging and rat-holing issues in bulk material storage with po...

Hydraulic vibrator for industrial hoppers

Optimize material flow and prevent blockages in bulk handling systems with a com...

Live bin bottom for difficult material discharge

Efficiently manage the discharge of challenging materials like biological...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

External electric motovibrator for increased safety in hazardous environments

Designed for environments with explosive...

Vertical conveyor for fine aggregates and minerals

Optimize the handling of abrasive materials with a vertical conveying ...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Chain conveyor for horizontal transportation

Efficiently handle diverse materials with a reliable chain conveyor, designed...

Terrier extruder for high volume material processing

Ideal for continuous high-volume processing, this extruder efficient...

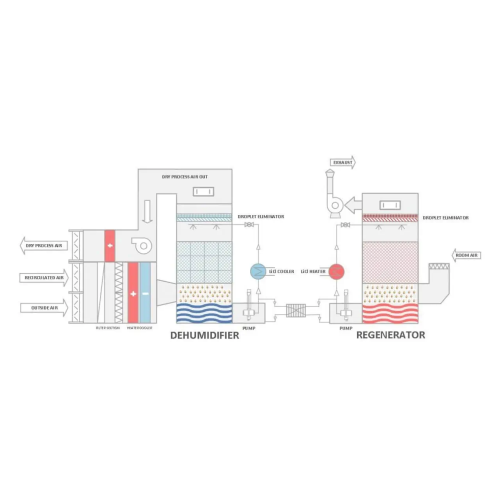

Industrial lithium chloride dehumidifier

Efficiently control air moisture and temperature with a solution that ensures prec...

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed ...

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Microalgae cultivation infrastructure

The microalgae cultivation infrastructure streamlines your production with integrated...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

Desktop bioprocessor for continuous biomanufacturing

Shrink your biotech facility to a bench-top unit, achieving seamless...

Dewatering screens for industrial applications

Efficiently transforming wet material into dry, manageable outputs, these d...

Mobile screening solution for sticky and wet materials

Effortlessly tackle challenging, sticky or wet materials with a mo...

Autoclavable photobioreactor for microalgae and bacteria cultivation

Optimize the growth of phototrophic organisms with...

Benchtop stirred fermenter for precise fermentation control

Optimize your fermentation and cultivation processes with pr...

Benchtop Sip fermenter for bioprocessing applications

Optimize your bioprocesses with precise control over fermentation a...

Autoclavable fermenters for small scale bioprocessing

Optimize your bioprocesses with configurable fermenters offering pr...

Benchtop electric mini fermenter for process development

Optimize your process development with a compact benchtop fermen...

Turbo separator for Ddg agglomeration

Efficiently eliminate clumping and improve flow in your distillation process, ensurin...

Organic material extraction for recycling

Achieve high-efficiency organic material separation for versatile end products l...

Seed conditioning system for edible oil processing

Optimize your oilseed processing with efficient moisture reduction and...

Industrial steel weighbridge for heavy load weighing

Optimize your material handling processes with precise weight measur...

Pit scales for industrial weighing

Optimize material flow and ensure precise load determination with a robust pit scale sol...

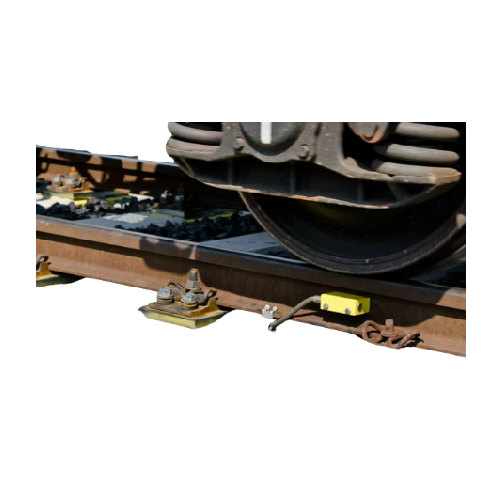

Train scales for torpedo vehicles

Streamline your steel production with precise and efficient weighing of torpedo vehicles,...

Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide lega...

Above-ground scales for weighing transport vehicles

Easily relocate your weighing solution for accurate load determinatio...

Scale hopper for bulk solid material handling

Ensure precise measurement and efficient transport of bulk solid materials w...

Industrial vacuum batch dryer for reducing moisture content

Achieve precise moisture control with a solution that handle...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Solid flow meter for continuous bulk material measurement

Ensure consistent and accurate measurement of bulk solid mater...

Bin weighing system kits for precise weight control

Ensure accurate material measurement in challenging environments with...

Dynamic high-speed railway weighing system

Prevent track damage and ensure safety by accurately weighing trains at speeds ...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Apron weighfeeder for sticky bulk materials

Optimally handle challenging, sticky materials with precision and consistency ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

U-belt conveyor for bulk material transport

Optimize your high-speed bulk material transport with this space-saving convey...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

En-masse chain conveyor for bulk material handling

Streamline your bulk material handling with a gentle, efficient system...

Tube belt conveyor for long-distance material handling

Ensure seamless and protective transport of bulk materials across ...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and...

Big bag discharger

Big bags offer suitable material handling for powder products from pharma and food ingredients to bulk and...

Oilseeds preparation plant

When producing customized flakes, pressed cakes, or other oilseed products, the oilseed preparati...

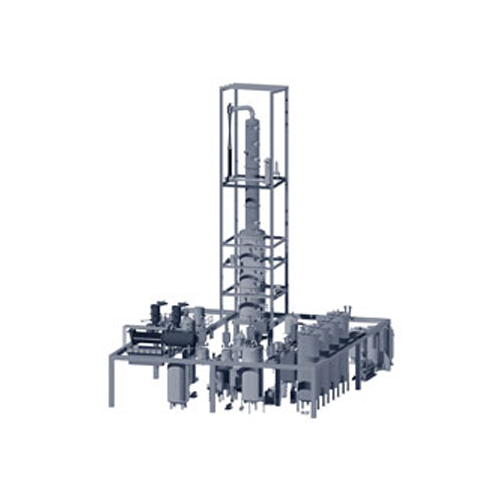

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Water oil separation centrifuge

Some industries, such as petrochemical, generate large volumes of oily wastewater due to the...

Ultrasonic spraying system for small scale coating and research processes

Ultrasonic spraying technology has the abili...

Ultrasonic spraying system for medium and large scale coating

When it comes to expensive chemical solutions and suspensi...

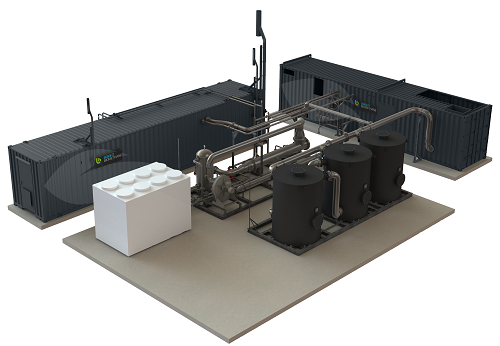

Large-scale biomethane production system

Membrane separation technology for biogas purification is considered as an effecti...

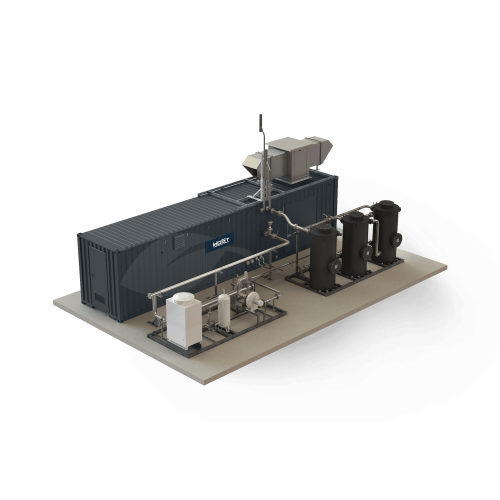

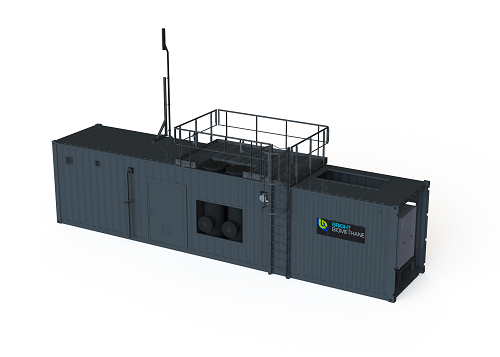

Modular biogas to biomethane system

The primary purpose of biogas upgrading technology is to increase the volumetric energy...

Small-scale biogas upgrading system

Biogas upgrading refers to the process of purifying biogas through separating methane f...

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Plug and play natural gas to hydrogen generator

Hydrogen is an all-purpose element and can be simply defined as energy’s S...

Belt dryer for sewage sludge

If your water treatment plant often facing difficulties with sewage sludge deposits, drying the...

Advanced anaerobic digestion with external separation

Factories of dairy products, palm and coconut oil, slaughterhouses,...

Waste to energy anaerobic digestion system

The food industry produces tremendous amounts of waste at food production facil...

Anaerobic EGSB wastewater treatment

If you are looking for a compact and sustainable solution to remove organic pollution f...

Biogas heating system

Traditionally, heating of wastewater would use boilers and heat exchangers. Biogas is a natural by-prod...

Anaerobic UASB wastewater treatment

If you need to remove organic compounds from your wastewater, the up-flow anaerobic slu...

Biological H2S scrubber

Raw biogas produced by digestion, for example during an anaerobic process is approximately 60% methan...

Online sampling system for larger scale bioprocesses

Accurate sampling is vital for improving a wide variety of industria...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Conveyors for recovery boilers

Recovery boilers recapture energy otherwise wasted in organic byproducts of industrial proces...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...

Annular gap expander for compound feed

Compound feed processing often requires a means of kneading and mixing input substra...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....