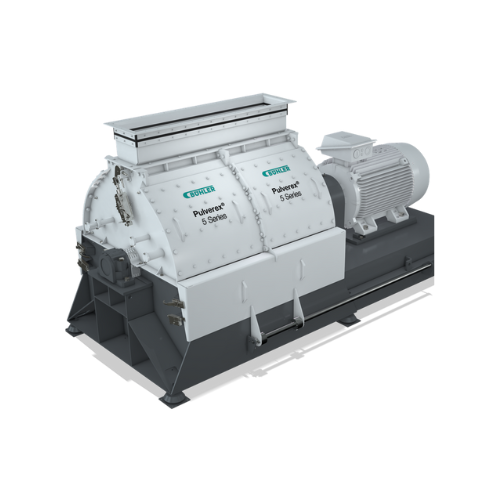

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this advanced pulverizer, designed for continuous high-speed operations across diverse materials from grains to alternative proteins. Perfect for producers focused on efficiency and fine granulation.

Grinds and Pulverizes Diverse Materials Efficiently

The Pulverex™ 5 Series from Bühler is a robust hybrid machine combining the strengths of a hammer mill and a pulverizer. Designed for heavy-duty applications, it efficiently grinds and pulverizes various materials, including grains, spices, and biomass, into consistent particle sizes. Its production process features a large screen area and double impact plates that enhance capacity while ensuring fine granulation. Capable of processing a wide range of products such as poultry feed, rice flour, and lithium-ion battery components, it supports high throughput demands, ideal for food processors and biomass companies.

With a hybrid design, the Pulverex 5 Series maximizes energy efficiency, consuming less power than traditional pulverizers, thanks to an optimized tip speed and air-swept mechanism. It seamlessly integrates into any production line with PLC control for comprehensive automation and remote monitoring. Constructed from abrasion-resistant materials, it promises longevity and minimal maintenance disruptions. For easy cleaning, the equipment provides fast access to wear parts, ensuring minimal downtime. Furthermore, Bühler offers customization options, including variable rotor speeds, to tailor performance to specific operational requirements.

Benefits

- Enhances production efficiency by maintaining high throughput with fine particle consistency.

- Reduces energy costs with its hybrid design that optimizes grinding speed and power usage.

- Minimizes maintenance expenses through easily replaceable wear parts and robust construction.

- Supports diverse applications from food processing to biomass, broadening operational flexibility.

- Integrates smoothly into automated systems, decreasing labor requirements and operational complexity.

- Applications

- Snacks, Grain, Cosmetics, Chocolate, Chemicals, Pulses, Paddy, Spices, Aqua feed, Biomass, Batteries, Cocoa, Animal feed, Alternative proteins, Pet food, Nuts, Food ingredients, Rice, Paints, Wheat, Oilseeds, Confectionery, Coatings

- End products

- Latex paint, Whole wheat flour, Wood pellets, Lithium-ion battery components, Poultry feed, Peanut butter, Split peas, Cornmeal, Fish pellets, Plant-based protein powder, Soy protein isolate, Ground spices, Varnish, Facial cream, Cat kibble, Almond flour, Sunflower oil, Chocolate powder, Paddy husk pellets, Rice flour, Lipstick

- Steps before

- Raw material processing, Dehulling

- Steps after

- Optical sorting, Packing, Palletizing

- Input ingredients

- raw materials, aqua feed ingredients, pulse materials, pet food ingredients, nuts, oilseeds, wheat, grain, rice, paddy

- Output ingredients

- fine granulation output, processed aqua feed, processed pulses, pet food, ground nuts, ground oilseeds, milled wheat, milled grain, milled rice, processed paddy

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Capacity

- High throughput

- Granulation

- Fine granulation

- Screen Area

- Large

- Rotor Type

- Staggered

- Tip Speed

- Optimized for efficiency

- Energy Consumption

- Low energy consumption

- Particle Size Distribution

- Uniform

- Design Type

- Hybrid (Hammer mill and Pulverizer)

- Wear Parts

- Abrasion-resistant steel

- Maintenance

- Low maintenance requirements

- Operation Mode

- Continuous

- Application Flexibility

- Single-stage or Dedicated fine grinding

- Air-swept Design

- Included

- Impact Plates

- Integrated

- Interrupter Plates

- Flow interrupters

- Working mechanism

- Hammer mill and pulverizer hybrid

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Low energy consumption due to hybrid design

- Changeover time

- Quick change of wear parts

- Automation level

- PLC / SCADA

- Cleaning method

- Manual / CIP

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- Cleanability

- Easy to clean

- Control panel type

- Touchscreen / Analog

- Integration possibilities

- PLC / SCADA integration

- Screen area

- Large screen area

- Rotor type

- Staggered / Clustered

- Wear parts type

- Abrasion-resistant steel

- Hybridity

- Hammer mill and pulverizer

- Impact plates

- Double impact plates