Spice Processing Equipment

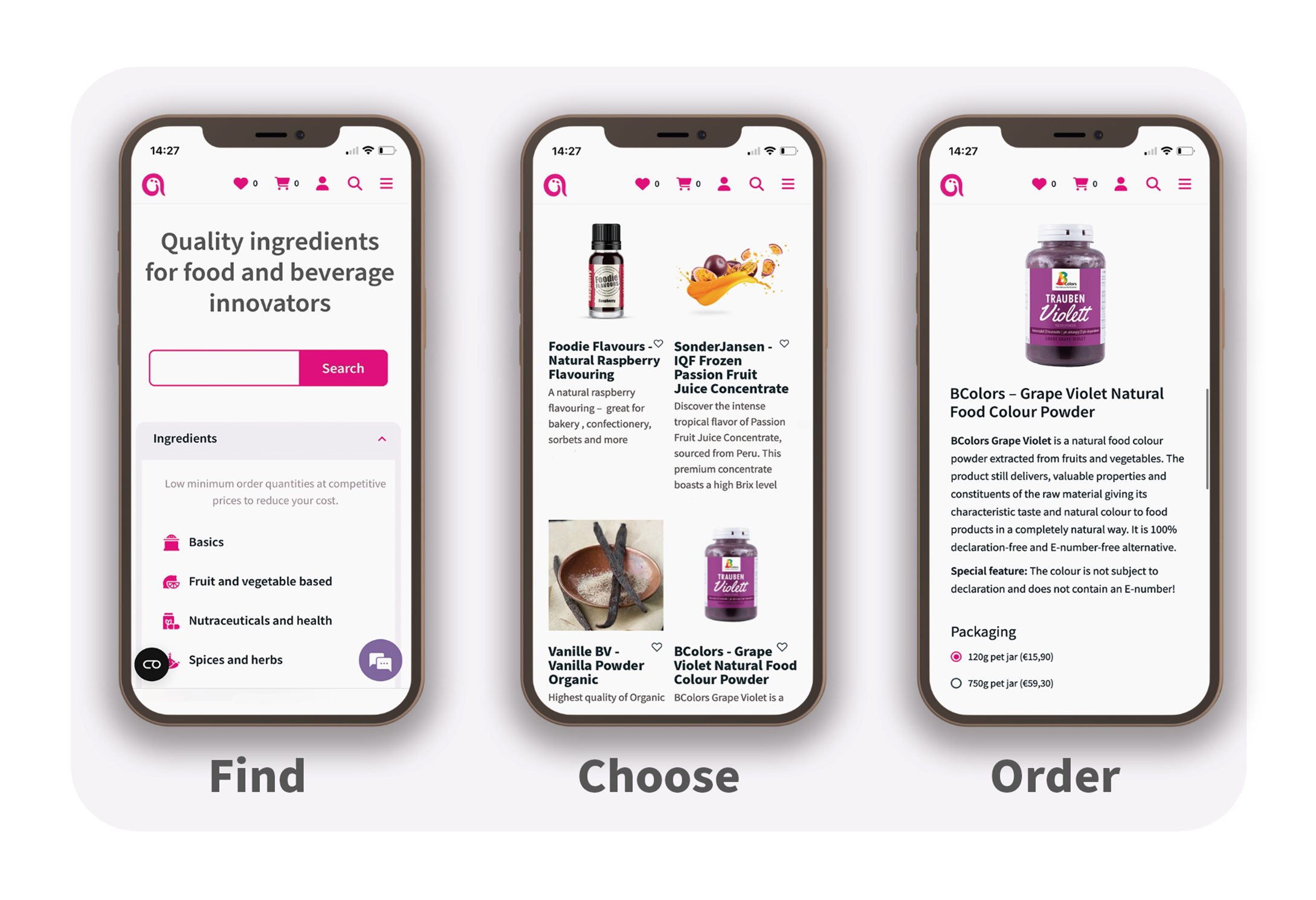

Find innovative spices equipment and connect directly with world-leading technology suppliers

Spice manufacturing is one of the world's oldest trading products. The word spice refers to any dried part of a plant other than the leaves and is used for seasoning and food coloring. Spices are made from dried barks, roots, berries, and twigs, while green leafy parts of plants are considered herbs. Well-known examples include cinnamon, chilies, star anise, ginger, garlic salt, turmeric, cumin, or pepper, as well as pre-mixed blends such as Masala, Five-Spice Powder, or Old Bay.

Technology picks for processing spices

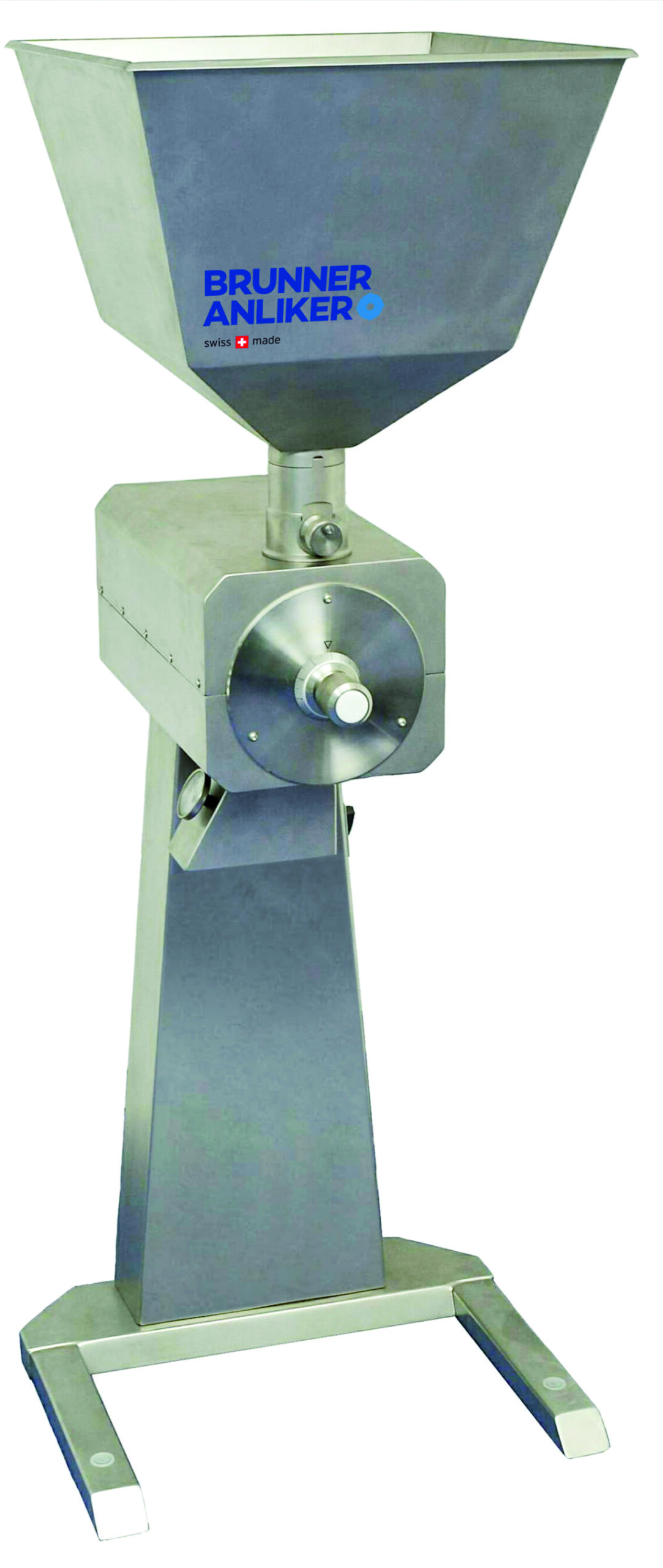

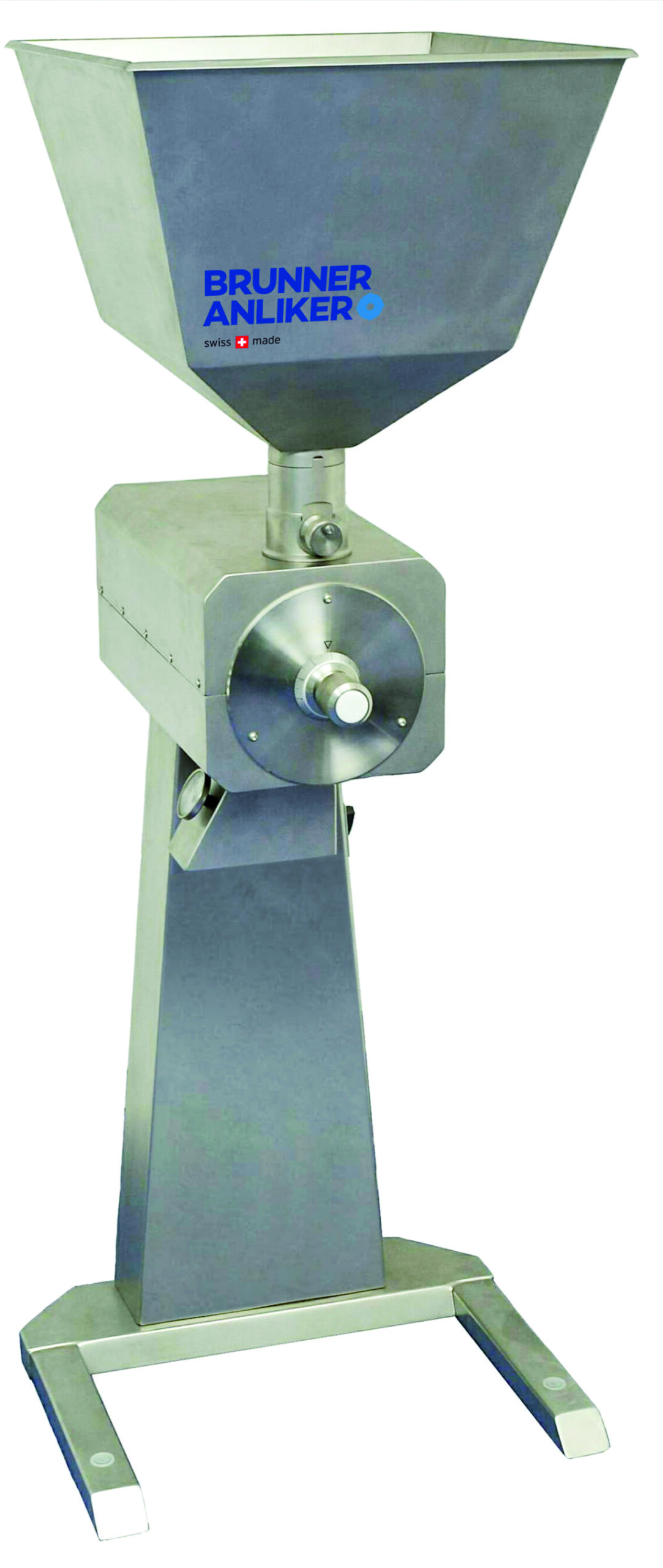

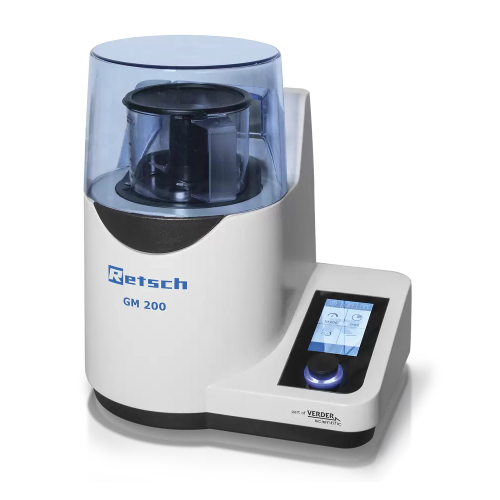

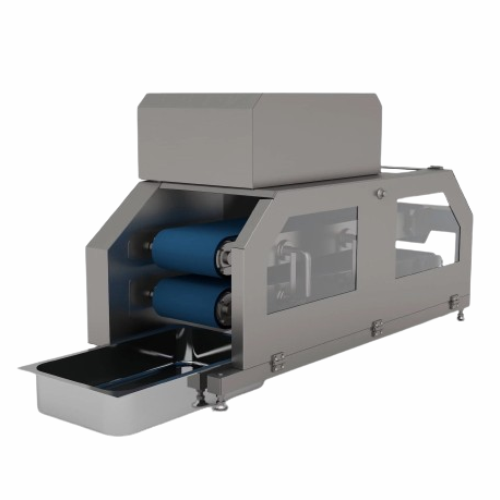

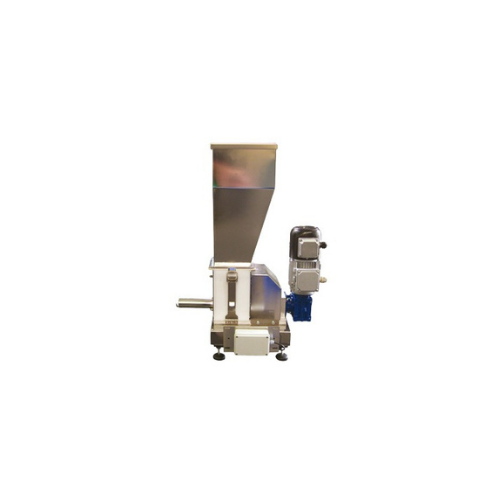

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

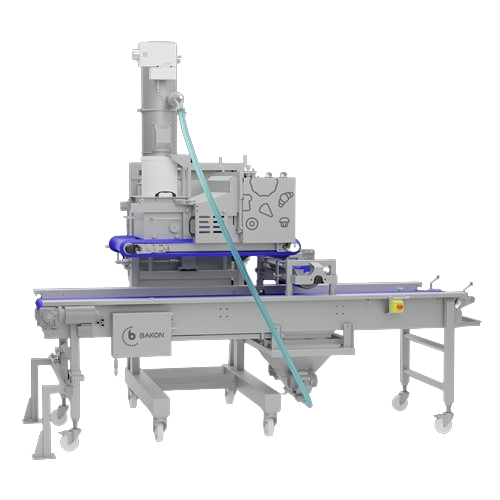

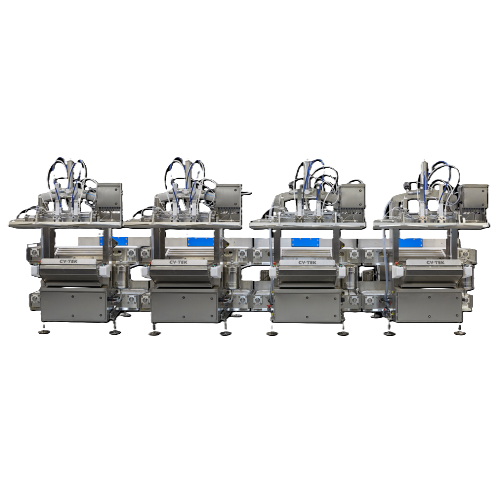

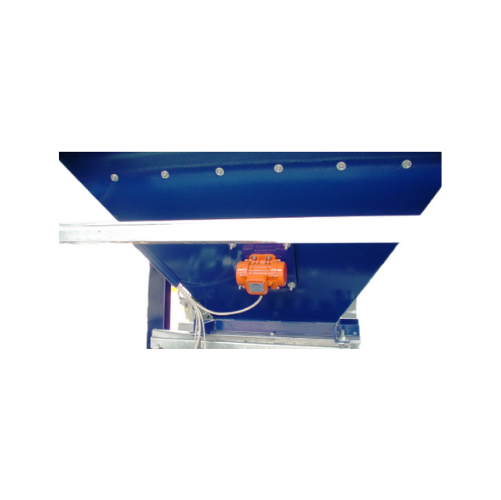

Spice doser for powdered and free-flowing dry vegetables

Optimize spice and dried vegetable packaging with precise dosing...

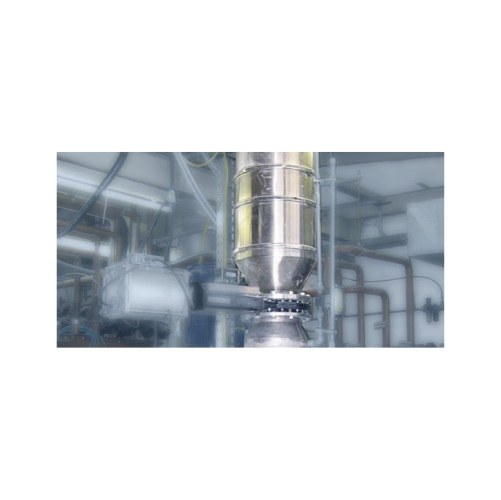

Ginger powder processing line

Optimize your spice production with comprehensive ginger powder processing, transforming fresh...

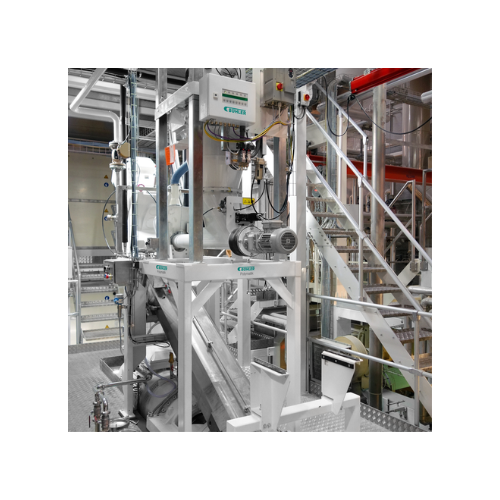

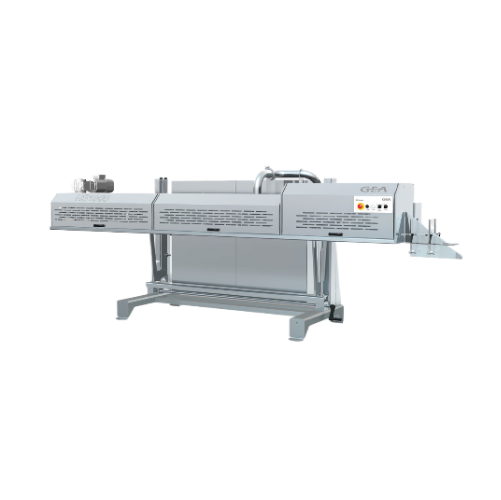

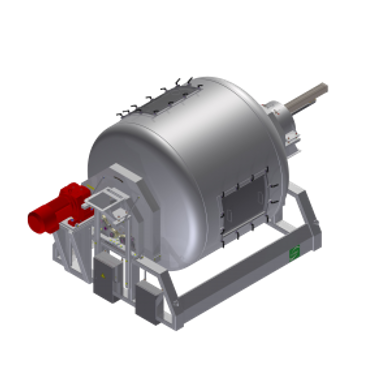

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Select your spices process

Tell us about your production challenge

When producing spices for export compliance with various legal requirements and specifications on food safety, hygiene, traceability and control are essential. Due to continuing problems with high levels of pesticides, preservatives, aflatoxins and food additives, as well as salmonella contamination, it is likely that controls within the spice industry will become stricter in the future.

Production processes for making spices

Gentle drying or dehydration methods, like infrared drying or microwave vacuum drying, are used to reduce moisture content and ensure shelf life, while maintaining aromas, volatile oils, and color. Classification, cutting, and grinding processes are challenged by temperature changes, wear and explosion risks. Cryogenic spice grinding techniques with nitrogen or conditioned air help to minimize loss of essential oils while grinding at sub zero temperatures. Spice mixes and blends require gentle mixing and homogenization to create dust-free, uniform, free flowing batches but also blend up liquids such as oils, fat and other extracts.

Producing cinnamon spice - drying process is the key!

Cinnamon is the dried inner bark of the tree species from the genus Cinnamomum, and is known for its brown color and sweet aroma and flavor. Shoots are first scraped with a semicircular blade and then rubbed with a brass rod to loosen the bark, which is split with a knife and peeled. The peels are telescoped one into another, forming a quill. After this, they are left to dry naturally for 4-5 days. However, true cinnamon thrives in a warm, wet climate thus it is necessary to use a mechanical dryer to complete the drying process.

Peppercorns sterilization process - incorporate infrared drying technology to decrease microbial load

Peppercorns are the unripe fruit of the piper nigrum plant. Collected fruits are immersed in boiling water for about 10 minutes, which causes them to turn dark brown or black in an hour. The softened outer coating is then removed by washing and rubbing or trampling. The whole peppercorns, when ground, yield black pepper. To reduce microbial load on peppers, such as TPC, E.coli, salmonella, yeast, mold, infrared drying technology can be used for sterilization of ground spices while avoiding overheating and loss of essential oils.

Filling, dosing and spice packaging technology

Powder characteristics such as particle density, flowability, dustiness and segregation tendency will determine the type of dosing and filling systems suitable for your product. Whole spices such as the seeds from cardamom and coriander can easily be ground into fine powders using automated grinding machines. Uniformity of a final blend or mixture is needed to guarantee the ingredient ratio. Whether you would like to pack your spices into small stick-packs, stand up pouches, containers or jars, it’s important to find a technology that matches your production process and scale.

Which spices technology do you need?

Spice doser for powdered and free-flowing dry vegetables

Optimize spice and dried vegetable packaging with precise dosing...

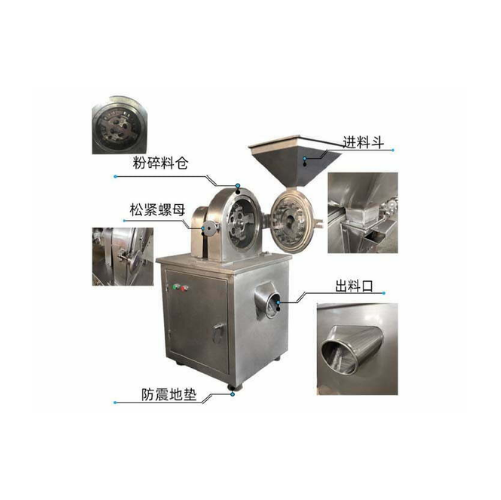

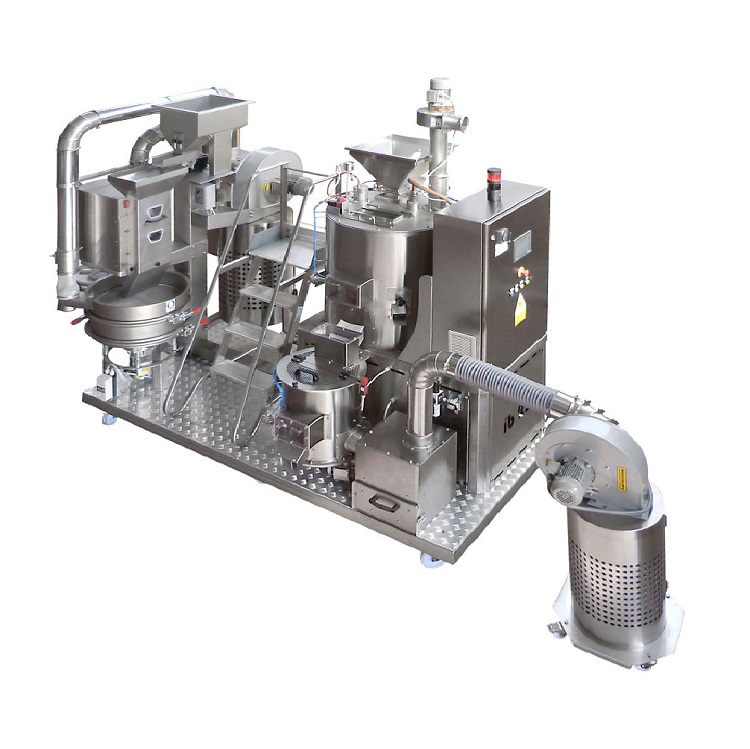

Spice and pharmaceutical powder grinder

Efficiently transform raw materials into fine powders, ensuring optimal consistency...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Precision sieve shaker for particle size analysis

Achieve precise particle size separation with a sieve shaker designed f...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Industrial bag tie-wrapping solution

Ensure your bulk packaging is reliably sealed with a tamper-evident tie-wrap, allowing...

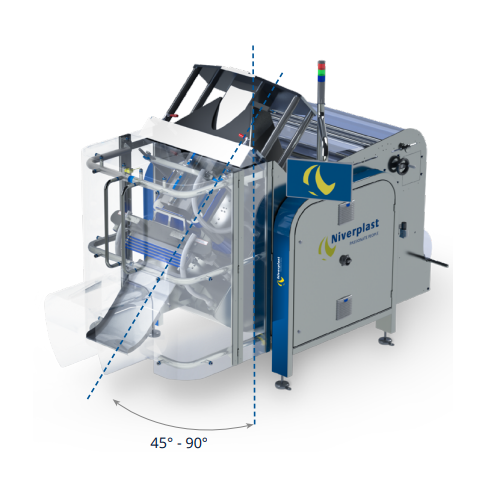

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

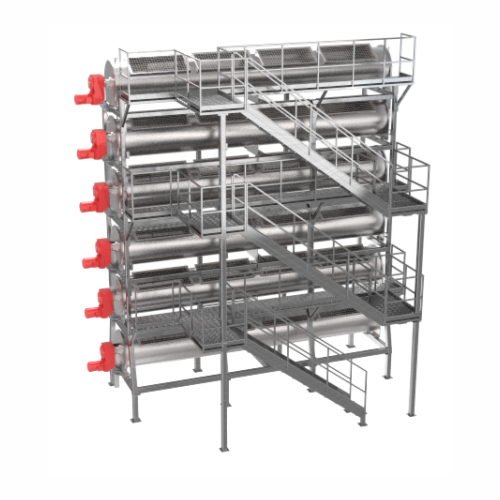

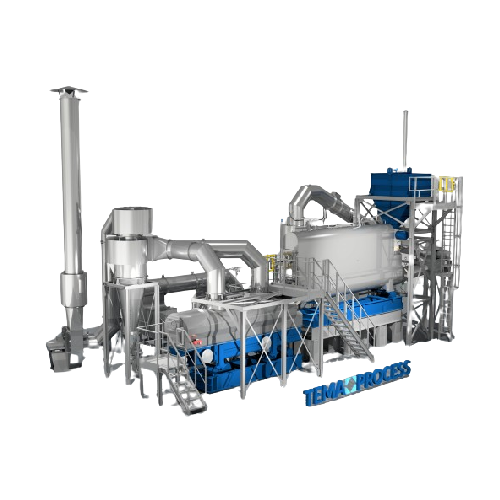

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

Manual patty formers for 180mm burgers

Effortlessly mold uniform 180mm patties from diverse ingredients, ensuring consisten...

Sesame seed roaster

Achieve consistently roasted sesame seeds and nuts with optimal moisture control, designed to enhance fla...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

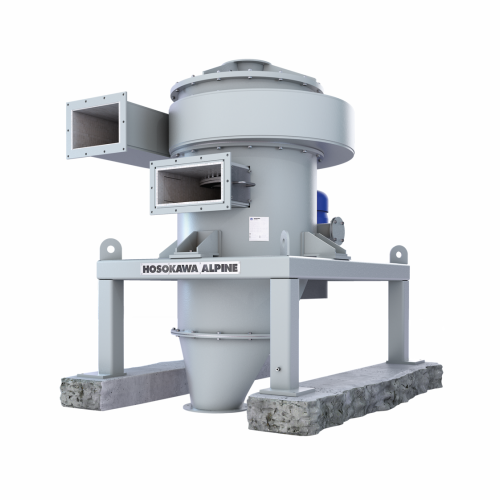

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

High precision weigher for small package weights

Achieve precise micro-dosing with unmatched accuracy at high speeds, opti...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

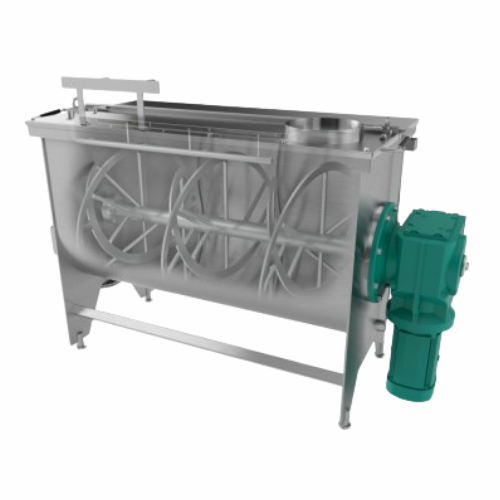

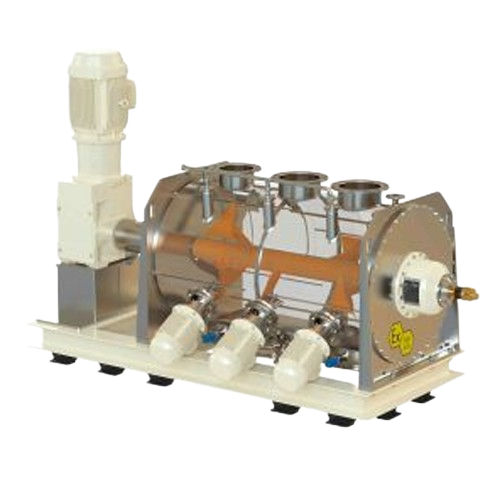

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

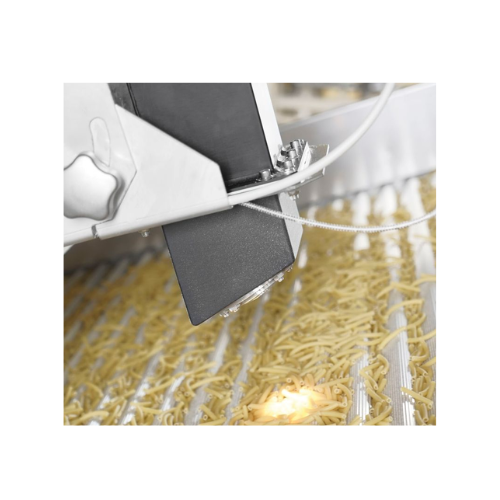

Optical sorter for frozen fruit and vegetable processing

Enhance your processing line’s efficiency with high-speed ...

Optical sorter for rice

Enhance your product quality by efficiently sorting and removing color defects and foreign materials ...

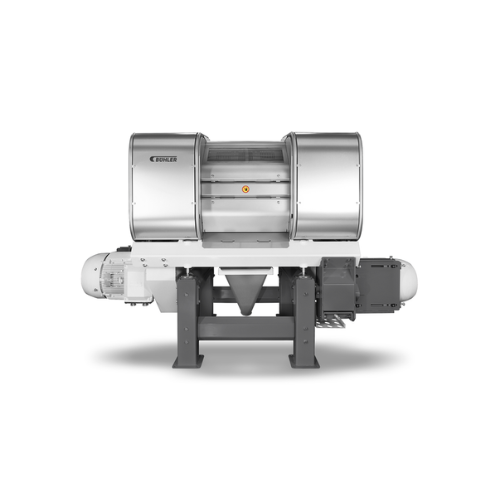

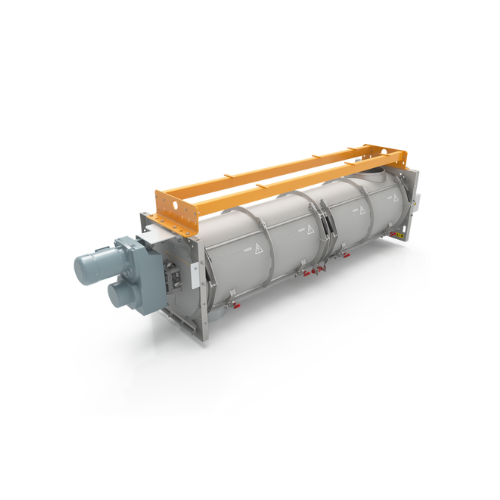

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

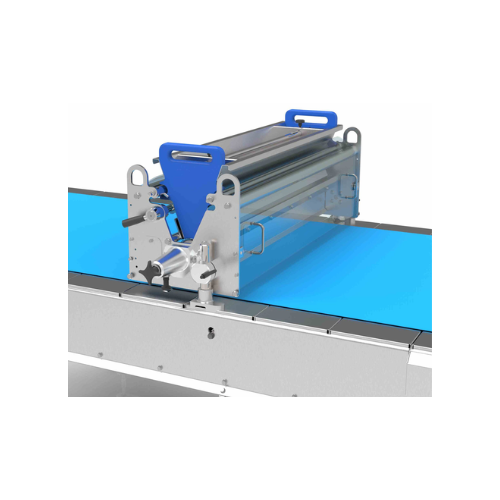

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Pulse huller for high throughput applications

Efficiently hull a wide variety of pulses and spices to enhance product qual...

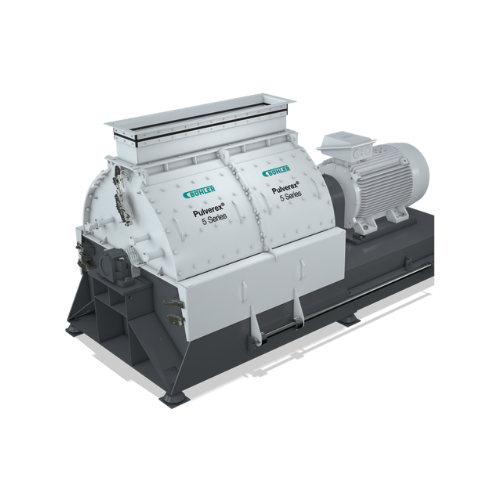

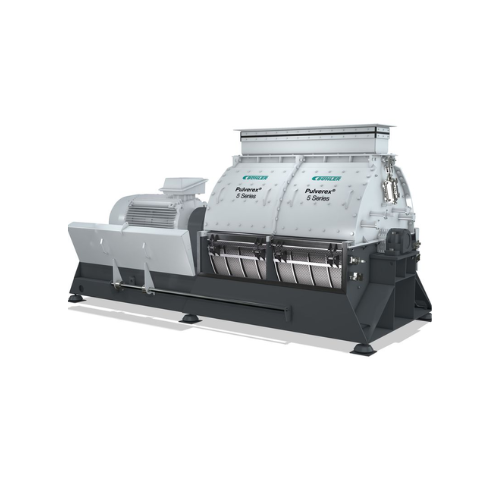

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

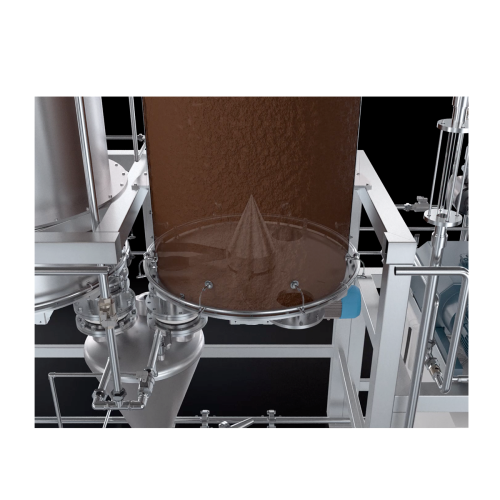

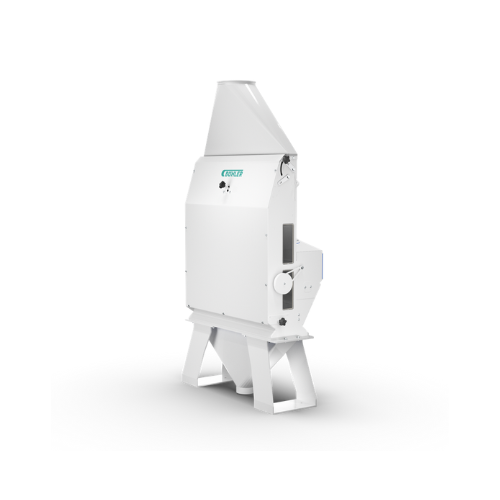

Winnowing system for cocoa processing

Achieve precise cocoa separation with a high-efficiency winnowing system designed for...

Grain screening for small to midsize operations

Streamline your grain processing with an economical screening solution tha...

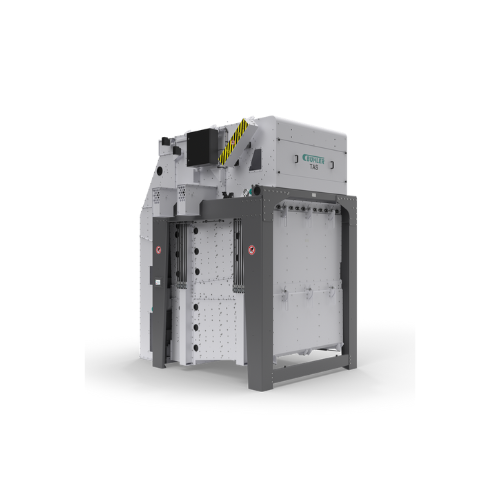

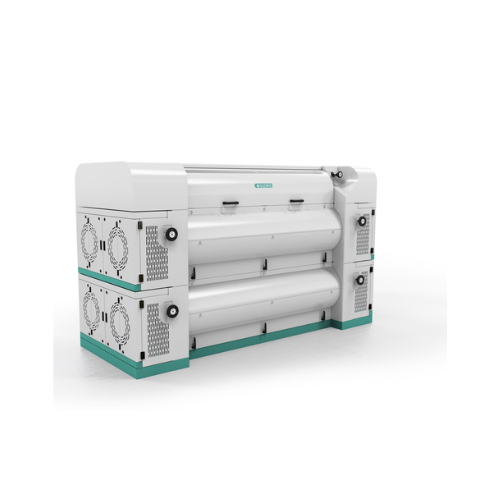

Small plansifter for grain milling

Optimize your grain milling with a compact plansifter designed for high-speed, precise s...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

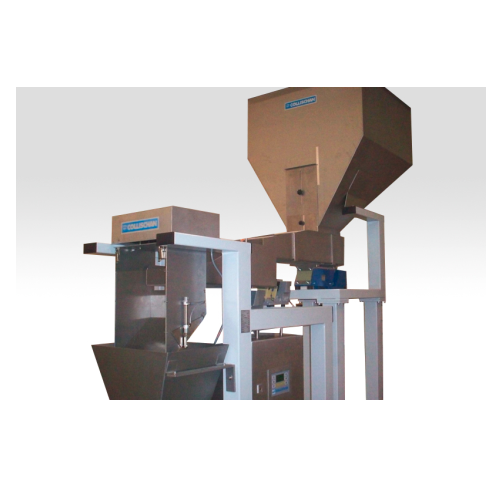

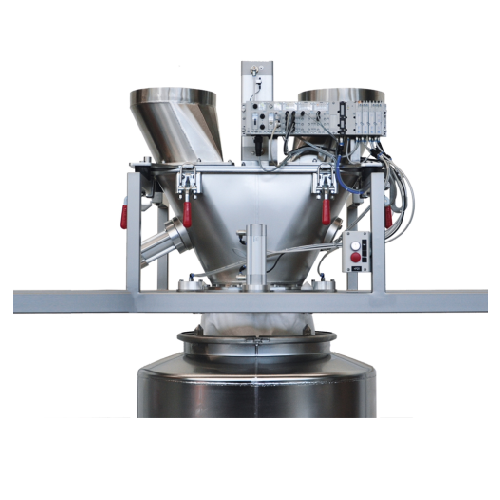

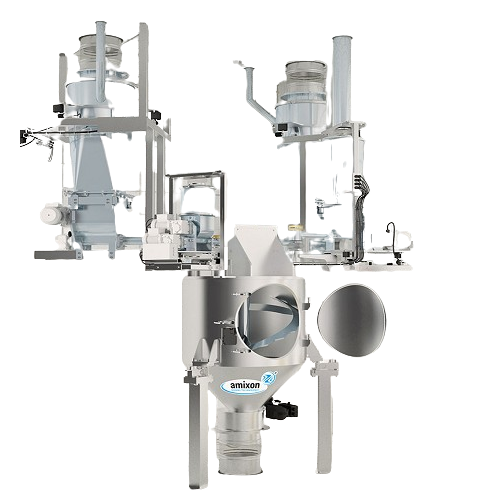

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

Big bag connection system for dust-free docking

Achieve dust-free docking and seamless discharging of bulk solids with an ...

Automatic seasoning mixer for food production

Effortlessly blend diverse ingredients with precision in your production lin...

Miniature auger filler for precise powder filling

Achieve precision filling with a compact, bench-top auger solution desi...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Form, fill, and seal system for single-use pouches

Achieve precise portion control and secure sealing with an integrated ...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Flour and crumb feeders for breading and pre-dusting processes

Optimize your breading and pre-dusting operations with ad...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Fillers for solid products

Optimize your production line with versatile fillers that ensure precise handling and packaging o...

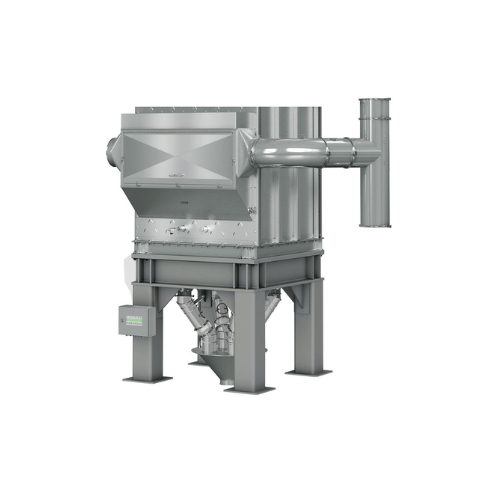

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

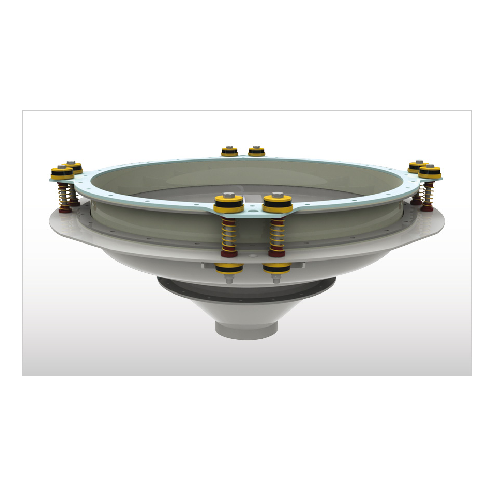

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Vibratory storage hopper with inclined screw conveyor

Enhance your production line efficiency with a vibratory storage ho...

Granule filling sachet machine

Ideal for optimizing packing operations, this granule-filling sachet machine ensures precise ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Small pepper stalk removal system

Effortlessly streamline your pepper processing with a machine designed to remove stalks w...

Commercial mango dehydrator

Optimize your fruit processing with a commercial mango dehydrator that ensures precise moisture ...

Ginger powder processing line

Optimize your spice production with comprehensive ginger powder processing, transforming fresh...

Chili powder milling machine

Transform raw spices into finely milled powders effortlessly with this high-speed grinding solu...

Garlic processing equipment for industrial applications

Streamline your garlic processing with equipment that automates p...

Dried chili cutting solution

Optimize your spice processing with high-speed cutting and seed separation, designed to deliver...

Industrial animal bone crushing solution

Efficiently transform hard animal bones into fine granular materials, enhancing nu...

Cryogenic mixer for frozen fruits and vegetables

Enhance frozen food quality with rapid, uniform mixing and precise temper...

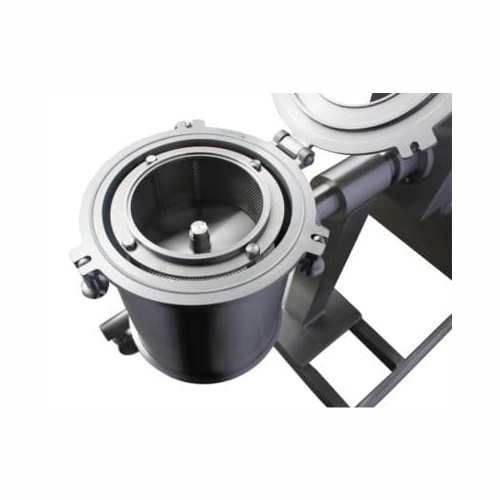

Vacuum rated vibro sifter for pharmaceutical materials

Ensure precise separation of impurities and achieve consistent par...

Electrostatic drum flavouring system for food industry

Enhance the consistency of your food products with precise flavour...

Electrostatic drum flavoring system for food processing

Enhance your snack production efficiency with a system designed t...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

Semi-automatic seaweed grinder for efficient algae processing

Optimize seaweed processing with this stainless steel grin...

Industrial batch mixers for pet food

Achieve homogenous mixing of complex multi-ingredient formulations with precision and ...

Rotary drum mixer for free-flowing materials

Achieve uniform mixing of heavy, free-flowing solids with precise control and...

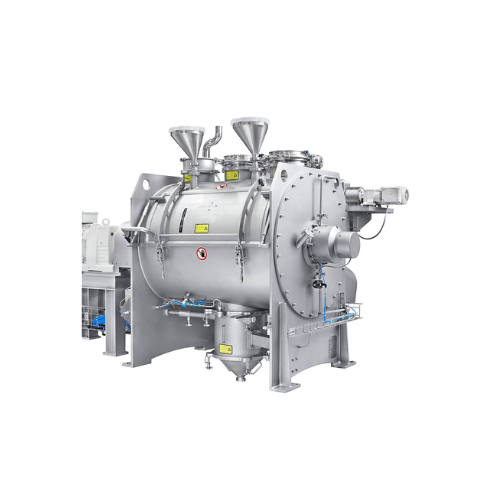

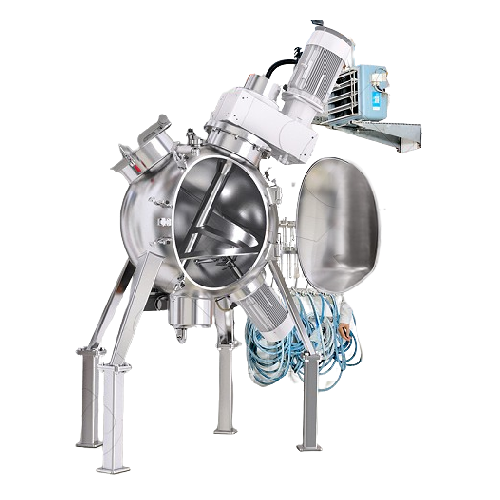

Industrial plow mixer for efficient solid and liquid mixing

Experience unparalleled mixing precision with high-speed plo...

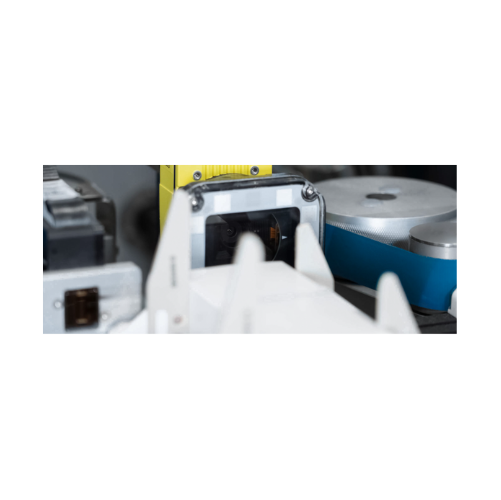

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Destoner for coffee beans

When you are roasting and grinding your own coffee beans, destoning is an essential step to gain f...

Hammer mill for coffee beans

Being able to obtain an on-point grinding is easily achievable with these hammer mills, from co...

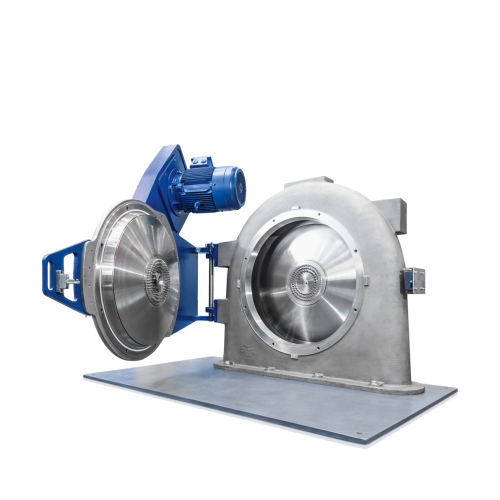

Stone mill for coffee beans

Traditional milling of coffee beans or seeds, with a stationary bedstone and a turning runner st...

Small batch filter press for oil seeds

Getting a high-quality oil filtration can be a challenging task, with a filtration ...

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

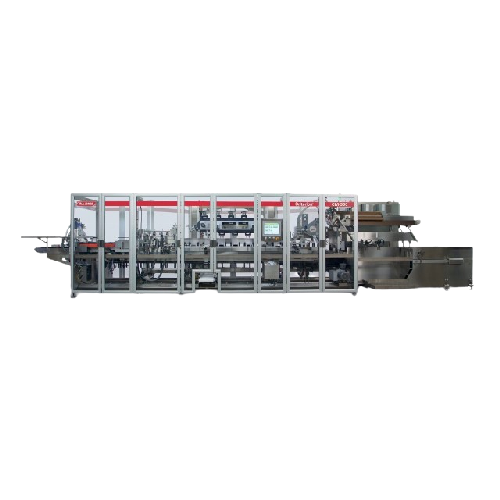

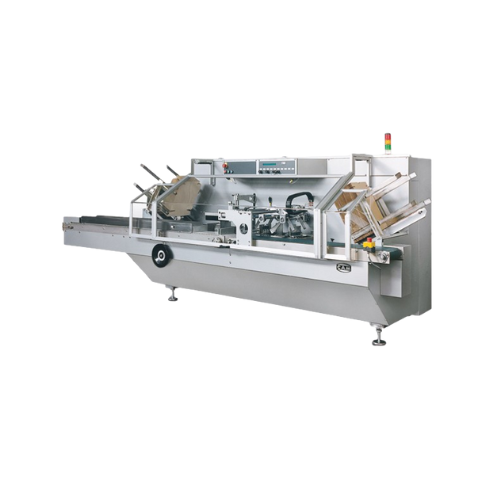

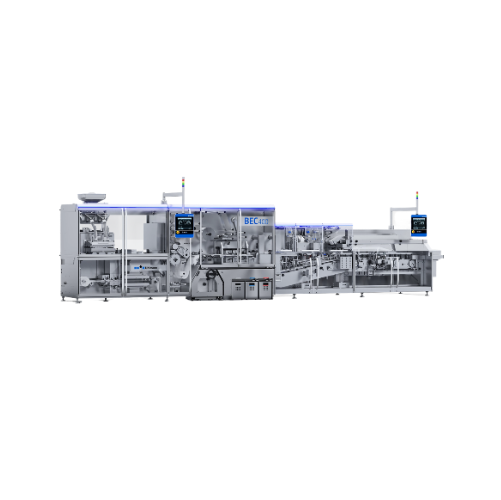

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

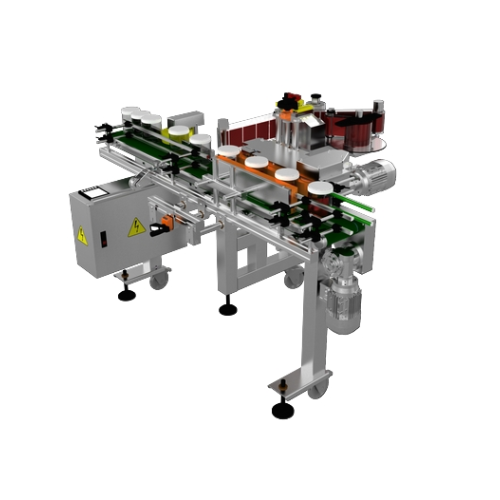

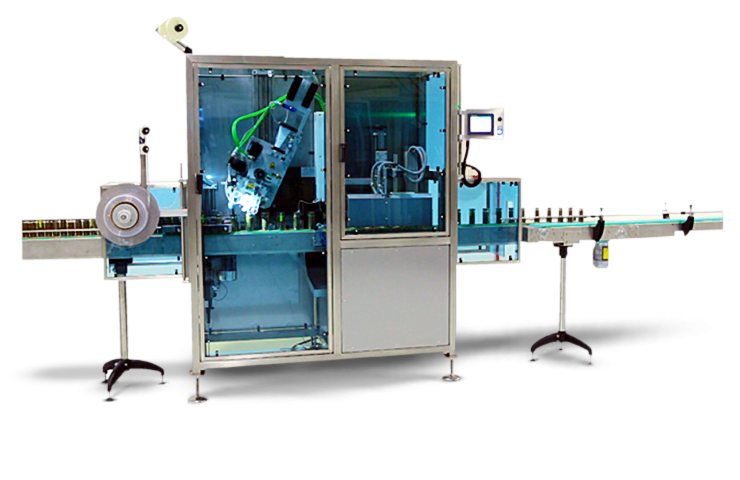

Semiautomatic labelling solution for cylindrical bottles

Effortlessly apply precise labels to various cylindrical and squ...

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

Food cutter for professional kitchens

Optimize your food preparation with precision mincing, cutting, and homogenizing, pre...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

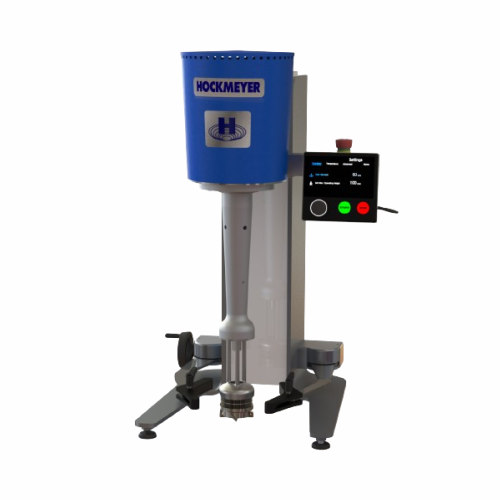

Mounting configurations for industrial agitators

Optimize your mixing processes with versatile agitators designed for effi...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Sesame seed washing system

Eliminate the bitterness and impurities from sesame seeds efficiently, setting the stage for high...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

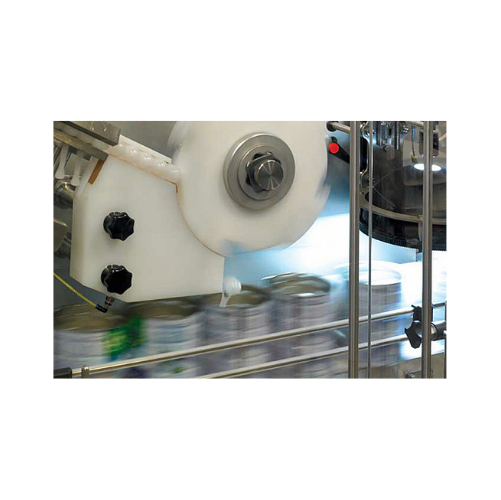

Container labeling for jars and bottles

Achieve precise labeling for diverse container shapes, from jars to square bottles,...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Heavy duty lump breaker for coarse and pre-grinding

Achieve consistent particle size reduction with this heavy-duty solut...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

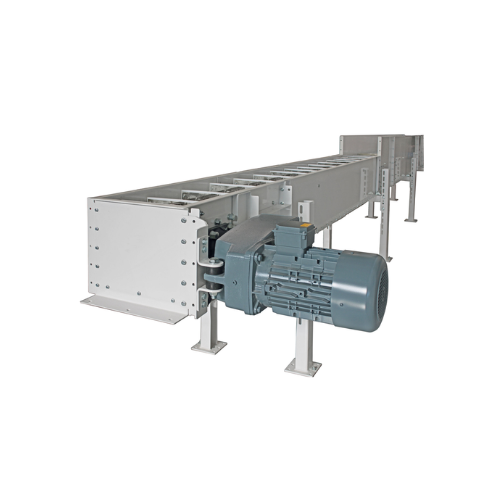

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ultrafine grinding mill for calcium carbonate slurries

Achieve precise particle size distribution in your mineral slurrie...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Classifier mill for ultra-fine grinding and precise particle size control

Achieve consistent ultra-fine particle distr...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for...

Empty container inspection for pharma packaging

Ensure ultra-clean packaging by detecting glass faults and contaminants be...

Double jacket cooling and defrosting system

Achieve precise temperature control in meat processing with a double jacket sy...

Homogeneous brine mixer for meat processing

Achieve rapid and uniform brine solutions with precise integration into your p...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

Vacuum tumblers for food processing

Optimize your production line with vacuum tumblers designed to enhance flavor infusion,...

Industrial mixing and processing plant for demanding products

Enhance your production line with precise mixing and proce...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Industrial tilting frying pan for precise roasting and cooking

Achieve uniform cooking and optimal flavor retention with...

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food text...

Cooked ham steaker

Achieve precise meat texture and uniformity with solutions designed for controlled cutting and pressing. I...

Schnitzel tenderizer with adjustable cutting pressure

For precise meat preparation, equip your production line with a sch...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

Small batch free fall mixer for food industry applications

Efficiently handle diverse ingredient integration for plant-b...

Vacuum marinater for meat production

Streamline your marinating process with precise vacuum control, enhancing flavor absor...

Integrated production system for food processing

Optimize your food production line with this versatile system, designed t...

Meat flattening and levelling system

Optimize your meat production with precise flattening and leveling, achieving consiste...

Meat tenderizing and flattening solution

Achieve consistent thickness and texture with this innovative flattening system, i...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

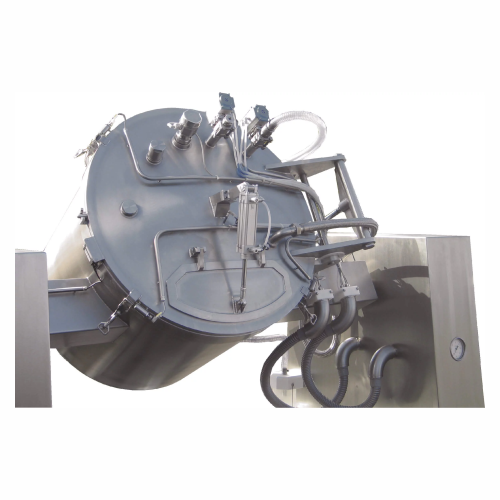

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

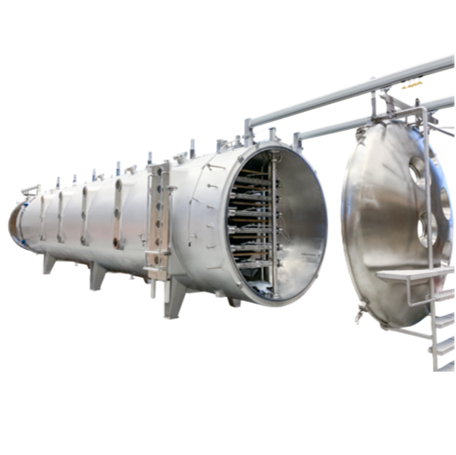

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Rotary continuous motion bottle cleaning solution

Ensure pristine product integrity by effectively eliminating particles ...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

High-speed continuous motion horizontal cartoner

Achieve seamless high-speed cartoning with precision cartoner systems des...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Indented separator for grain quality control

Achieve precise grain length separation with an adaptable indented separator,...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

High-throughput grain cleaner

Maximize efficiency in grain processing with a high-throughput cleaner designed to handle dive...

Vertical hammer mill for feed and grain processing

Optimize your milling operations and improve energy efficiency with th...

Vibro discharger for silo emptying

Achieve complete and even discharging of bulk materials from various silo types, ensurin...

Advanced grain cleaning system

Optimize your grain processing with a cutting-edge cleaning solution that efficiently removes...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Multi-pass pet food dryer for consistent moisture content

Achieve precise moisture control and enhanced product quality ...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain sifter for milling applications

Optimize your grain processing by efficiently sifting and sorting a variety of produc...

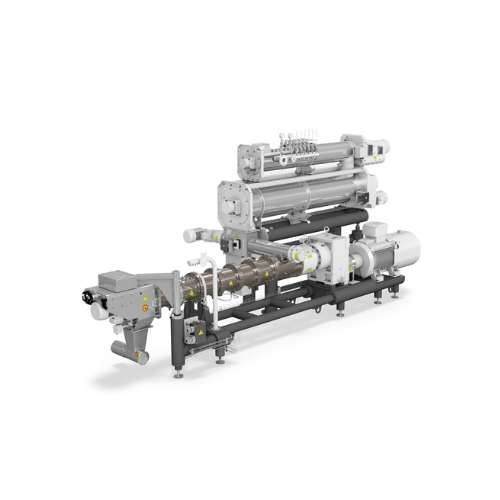

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

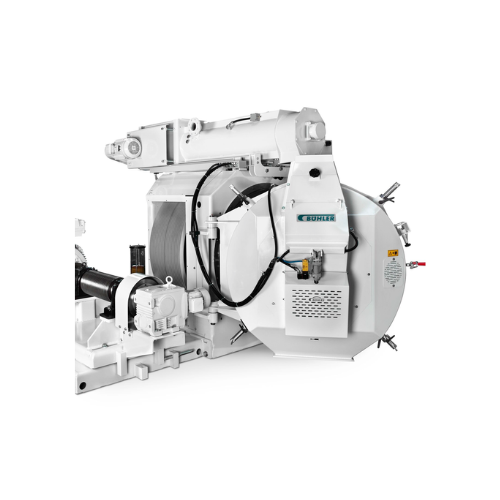

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied mater...

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Optical sorter for rice defect detection

Achieve exceptional sorting precision by detecting and removing color and foreign ...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for unif...

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

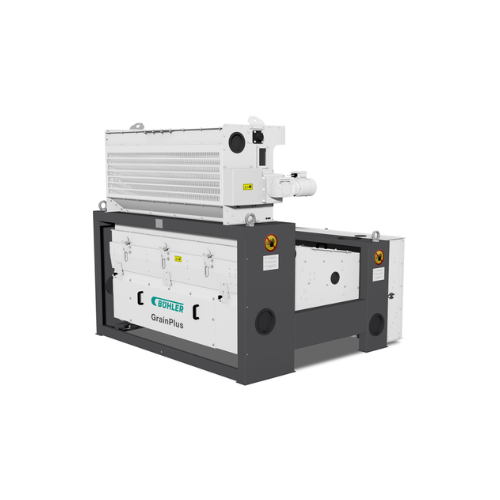

Grainplus screening system for grain quality

Ensure precision in grain cleaning with a compact and efficient sieving techn...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Flat storage system for grain

Designed to accommodate various agricultural products, this flat storage system ensures effici...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Grain cleaning drum sieve

Optimize your grain processing with this versatile pre-cleaning solution designed to efficiently r...

Malt conditioner for optimal brewing efficiency

Enhance your milling process with precise moisture control, ensuring optim...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Soybean dehulling separator

Enhance the quality of your oilseeds and grains by efficiently separating hulls and impurities, ...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Tubular screw conveyor for grain transport

Efficiently discharge and dose raw materials with high precision, ensuring seam...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Air-recycling aspiration channel for grain cleaning

Optimize grain processing with an innovative air-recycling system tha...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Oilseed screening solution for soybean and canola

Optimize your grain and oilseed processing with a high-throughput scree...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Cracking mill for oilseeds and feed processing

Maximize your production efficiency with advanced cracking and milling solu...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

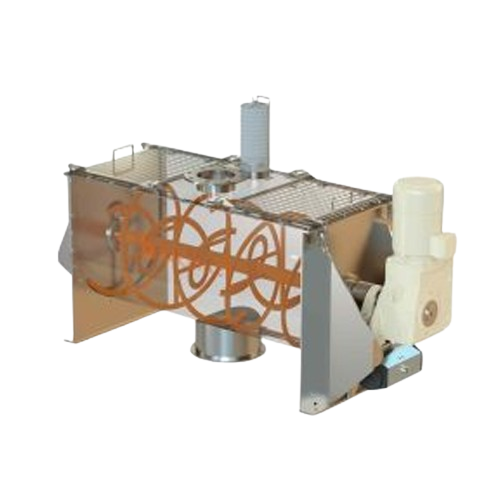

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

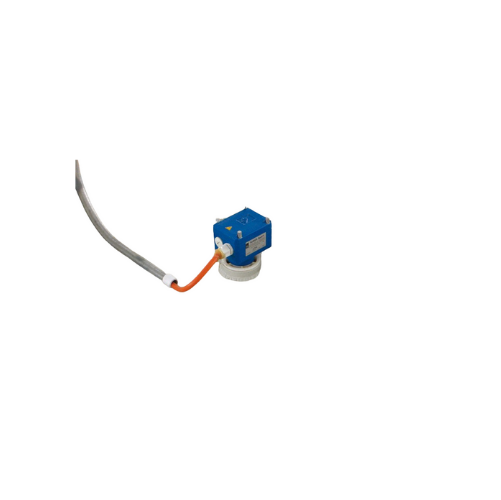

Sampling unit for continuous sampling in industrial processes

The PRS sampling unit ensures precise and uncontaminated s...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Dust-free docking collar for containers and bins

Achieve seamless, dust-free connections between containers and processing...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Dust-tight docking for dosing units to bulk solids containers

Ensure seamless, dust-free transfer and dosing of bulk sol...

Batch automation system for fast and precise weighing

Achieve unmatched precision and speed in batch processing with this...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

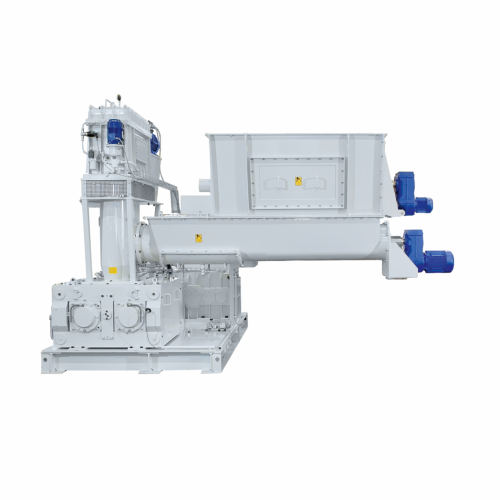

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Conical vacuum dryer for viscous materials

Achieve precise drying and mixing of moist and viscous materials, ensuring cons...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

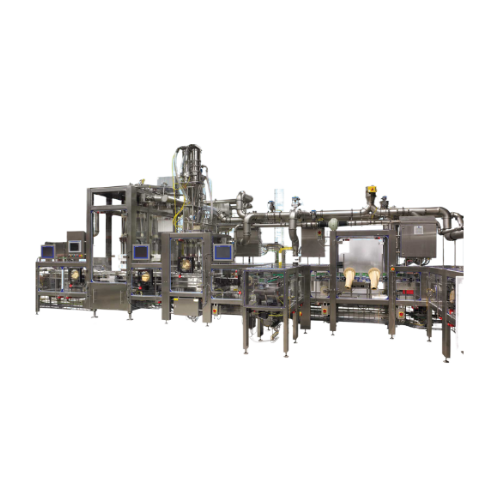

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Mobile lifting column for drum handling

Streamline your powder and drum handling operations with this versatile mobile lift...

Hygroscopic material lump breaker

Ensure seamless processing by breaking down compacted or hygroscopic powders efficiently,...

Tamper evident heat tunnel for safety banding

Achieve precise and consistent tamper-evident sealing on containers with a h...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Seasoning system for snack products

Optimize your snack production with precise oil, salt, and seasoning distribution, ensu...

In-line gassing system for powder processing

Optimize shelf life and quality of your powdered products by effectively redu...

High-speed container reject system

Ensure product integrity by swiftly rejecting non-compliant containers at speeds up to 3...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Rotary drum breader for irregular-shaped food coating

Enhance your food products with precise, customizable coating using...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Rotary feeder for bulk material conveying

Enhance your material flow with precise metering and efficient conveying, ensuri...

Continuous pneumatic silo air filtering system

Ensure clean and efficient pneumatically conveyed materials by integrating ...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Air cannons for resolving bulk material flow issues

Solve bridging and rat-holing issues in bulk material storage with po...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Vacuum dispersion system for laboratory applications

Achieve precise mixing and homogenization under vacuum conditions, e...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Industrial food processor for diverse applications

Optimize your production line with a versatile processor capable of ch...

Industrial dicing solution for food products

Enhance processing efficiency with high-speed dicing and slicing solutions, e...

Industrial vegetable protein processor

Achieve precise size reduction and consistent texture in food processing with this h...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Brushing systems for agricultural produce

Enhance the precision and efficiency of fruit and vegetable processing with vers...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Screw conveyor for grain or finished products

Optimize your production line with a space-efficient screw conveyor designed...

Industrial roller mill for high-stability milling

Optimize your milling process with a high-speed roller system designed ...

Pneumatic cyclone for effective product-air separation

Optimize particle separation with high-speed pneumatic cyclones, e...

Compact food dehydrator for fruits and meats

Achieve precise dehydration of fruits, vegetables, and meats with a compact s...

Large-capacity commercial food dehydrator

Achieve precise dehydration for a wide range of food items with unmatched consis...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

Electric meat grinder for efficient meat processing

Streamline your kitchen operations with a robust meat grinder, engine...

Volumetric twin screw feeder for powder and micro-granules

Optimize your production flow by ensuring consistent and prec...

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Conveyors for food packaging metal detectors

Ensure seamless integration and safety in food processing lines with conveyor...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Volumetric auger for powder weighing and depositing

Ensure precise powder weighing and depositing for consistent product ...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Multifunctional cooking kettle for commercial kitchens

Optimize your batch cooking processes with an all-in-one solution ...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

Large capacity cooking kettle for industrial kitchens

Optimize your cook-and-chill production with a versatile cooking ke...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Automatic liquid filling solutions for various containers

Ensure precise liquid packaging for diverse container types, e...

Semi-automatic capping solutions for small to medium enterprises

Streamline your packaging line with versatile capping s...

Semi-automatic capping solutions for small to medium production

Streamline your capping process with versatile, customiz...

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this be...

Industrial dust collection system

Optimize your process by efficiently capturing and removing airborne dust particles, ensu...

Continuous bulk fluid bed dryer

Achieve rapid and energy-efficient moisture removal across diverse materials with our advanc...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed ...

Ventilation and dehumidification for meat processing plants

Achieve precise humidity and condensation control in meat pr...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

Garlic splitting and peeling line

Streamline garlic processing with this high-speed line designed to efficiently split, pee...

Industrial ginger slicer for efficient vegetable processing

Achieve precise vegetable slicing with high-speed efficiency...

Fruit and vegetable drying equipment

Achieve optimal moisture control for your fruits, vegetables, and herbs with versatile...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Industrial crusher for size reduction and waste recycling

Optimize your production line with versatile and robust crushi...

Infrared moisture analyzer for lab and production use

Achieve precise and reliable moisture analysis with minimal time an...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Gentle mixer for tea blending

The blending process is critical to the flavor quality of tea. But the physical impact of the ...

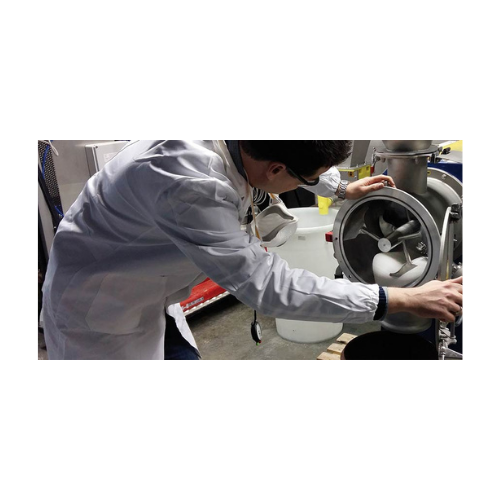

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Non-Destructive Crack Detection Vessel Testing

Using traditional types of inspection methods when inspecting vessels may p...

Spray Dryer Crack Testing Services

Spray dryers undergo multiple thermal cycles and may develop cracks as the metal becomes...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Flexible chocolate tablet wrapping machine

In the overcrowded and competitive confectionery industry, attractive chocolate...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Industrial tunnel dryer for food sector

Dry foods are popular consumables and have their place on the market. In cases wher...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Blow off system for containers

Packaging powders into plastic or glass containers often leaves a residue that needs to be re...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Screener and separator of dry powder

Many industries require the effective screening and separating of a range of dry powde...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Food vacuum conveyor

Widely used in industries where a high rating in food quality is imperative.

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

Infrared rotating drum steriliser

Sterilisation of foodstuffs is vital to maintain uncompromising standards of hygiene and ...