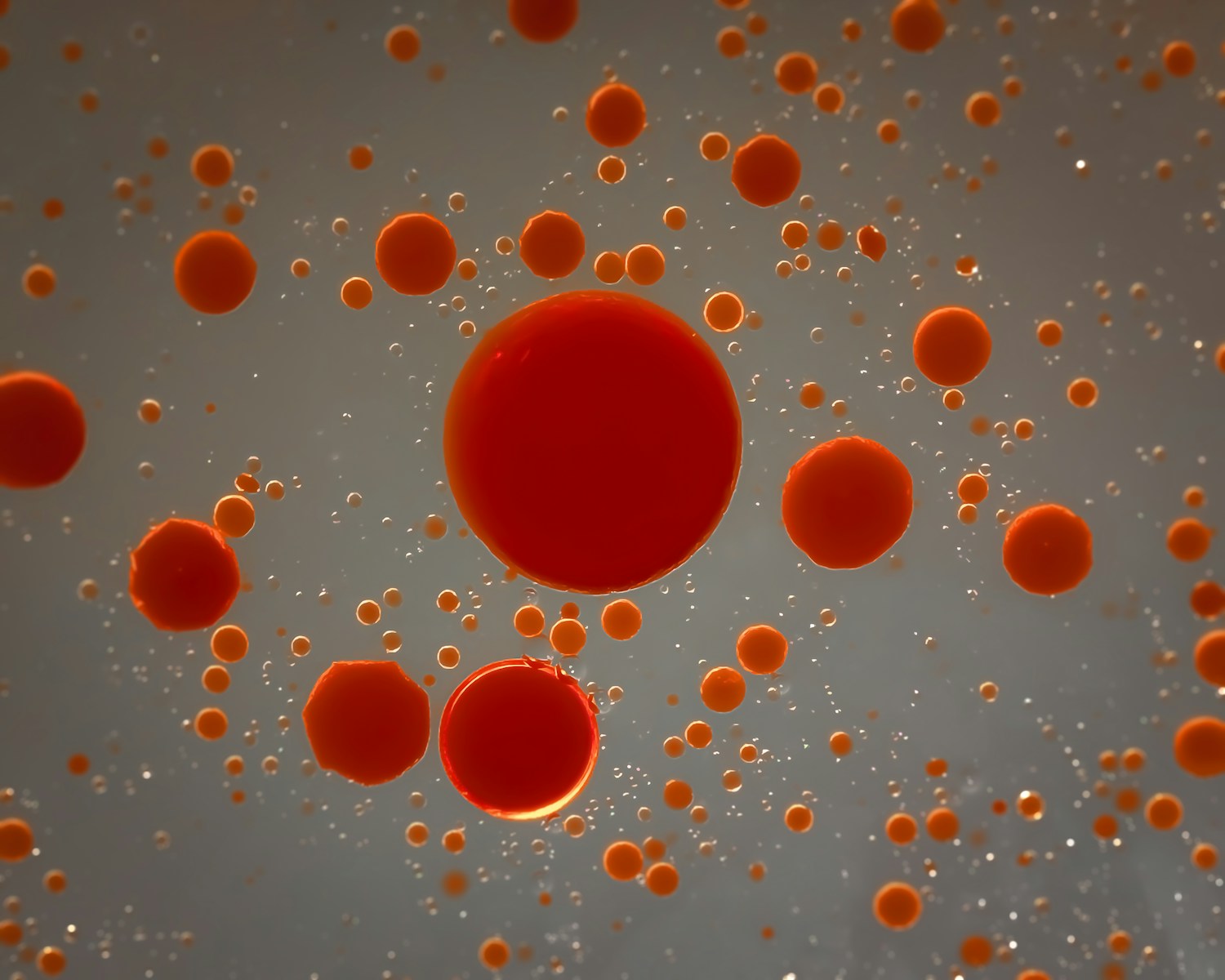

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food textures while maintaining production reliability. Perfect for enhancing consistency in ready-to-eat meals, cheese spreads, and plant-based products, this equipment guarantees optimal mixing and temperature control in both continuous and batch operations.

Processes and Emulsifies Diverse Food and Chemical Products

The BestCut from GLASS GmbH & Co. KG is a continuous comminution and emulsification system designed for precision processing in food and chemical industries. Utilizing the proven rotor-stator principle, it ensures fine comminution with replaceable 150mm cutting inserts and variable speed control for optimal flexibility. Ideal for producing ready-to-eat meals, plant-based burgers, and chemical emulsions, the system boasts a cutting gap range from 0.1mm to 3mm. With PLC integration and temperature monitoring, it offers production reliability with reduced energy consumption. Constructed for hygiene and durability, the machine features an encapsulated motor and polygon shaft, while adhering to EHEDG guidelines. Easy assembly and maintenance are enhanced by its design, and it supports customization for specific processing needs.

Benefits

- Achieves precise product consistency, enhancing quality control.

- Enhances production efficiency with continuous processing capabilities.

- Minimizes energy use with optimized motor control, reducing operational costs.

- Supports rapid product changeovers with easy disassembly.

- Ensures hygiene compliance and safety with EHEDG-guided design.

- Applications

- Chemistry, Convenience food, Meat production, Confectionery, Vegetarian, Cheese, Spices, Vegan, Delicatessen

- End products

- Cheese spreads, Gourmet pâtés, Herbal blends, Plant-based burgers, Sausages, Caramel candies, Chocolate confections, Chemical emulsions, Ready-to-eat meals, Tofu

- Steps before

- Meat Preparation, Ingredient Mixing, Product Slicing

- Steps after

- Packaging, Cooling, Quality Assurance

- Input ingredients

- convenience food, delicatessen, cheese, vegetarian, vegan, meat, confectionery, spices, chemistry

- Output ingredients

- fine comminution, emulsified products

- Market info

- Comminution Type

- Continuous

- Comminution Precision

- Fine

- Comminution Diameter

- 150 mm

- Cutting Gap

- 0.1 mm to 3 mm

- Variable Speed

- Yes

- Rotor-Stator Principle

- Proven

- Temperature Monitoring

- Yes

- Motor Encapsulation

- Yes

- Working mechanism

- Rotor-stator principle

- Integrated steps

- Comminution and emulsification

- Batch vs. continuous operation

- Continuous

- Automation level

- Variable speeds

- CIP/SIP

- Temperature monitoring

- Changeover time

- Easy assembly and disassembly

- Food product type

- Convenience food, Delicatessen, Vegan, etc.

- Processing application

- Cutting, Mixing, Grinding