Frying systems

Find innovative frying equipment and connect directly with world-leading technology suppliers

Frying was an early method for preserving food. The most common technique, immersing foods in boiling oils, dehydrates the items and decreases microbial growth. But even with alternative decontamination and preservation methods, frying remains a popular cooking technique. The oils add complexity to the natural flavors and textures of foodstuffs. One of the main challenges of fried products is maintaining oil freshness. Industrial frying equipment processes large volumes of food homogeneously by strictly controlling the temperatures in the frying chamber. However, oil efficiency is also crucial, and temperature control must balance oil levels in the line.

Select industrial frying equipment according to your end product

Industrial fryers can process large amounts of food in an even fashion on a commercial scale. The ingredients are loaded and dosed with oil according to your recipe specifications before being conveyed through the frying chamber in oil, operating at constant intensity. In the next step, the food goods undergo de-fatting and any further flavoring or coloring that might be required after the deep frying process.

There are many different types of industrial fryers, and some depend on the kind of food you’d like to produce. For example, french fries will require a separate fryer compared to crisps.

Industrial frying technology is used to process savory snacks

We often think of fryers being utilized for French fries and other breaded products such as fried chicken. But industrial frying equipment is used for processing a wide array of food products that are common all across the globe.

Almost all of our favorite salty snacks are deep-fried. These include crisps, nacho chips, nuts, pellet snacks, and much more.

Reduce oils with an industrial air fryer system

We tend to also associate a deep fryer with hot oil and the cooking of products like fried fish. However, there are various ways in which these food items can be fried. This will depend on the type of fryer used in the manufacturing process.

For example, Air frying is a relatively new method that saves a lot on production costs and reduces the need for large quantities of oil.

There's a Difference Between Industrial and Commercial Fryers

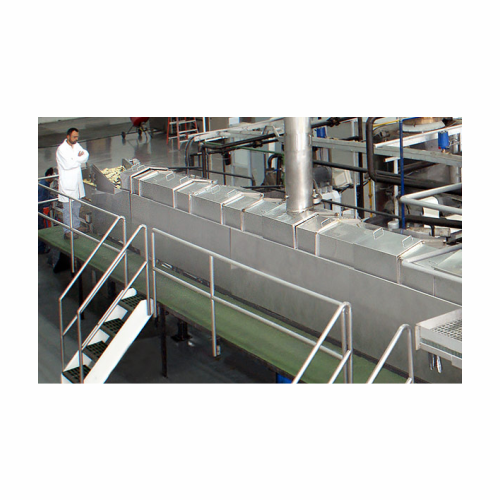

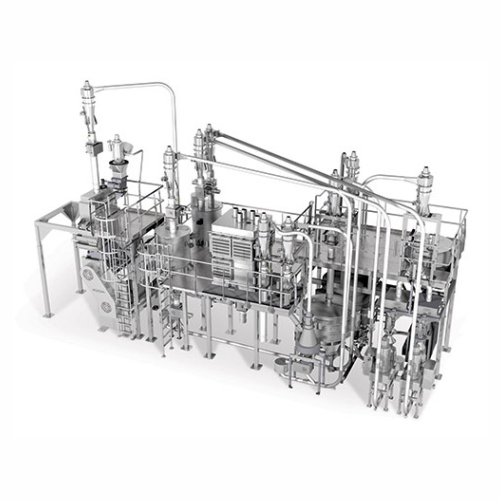

On the contrary, industrial frying requires enormous pieces of heavy-duty machinery and equipment to achieve a much larger scale output. Typically, industrial machines are looking to fry products to ensure that large quantities are produced to meet manufacturing specifications continuously.

How Do Industrial Fryers Work?

Automation, uniformity, quality, and efficiency are of great importance when frying on an industrial scale. This is because manufacturers want to maximize their output with the highest quality possible while reducing costs and saving as much time as possible.

However, to understand how industrial fryers work, it is first essential to determine the type of frying that needs to be done. The two most common types are continuous frying and batch frying.

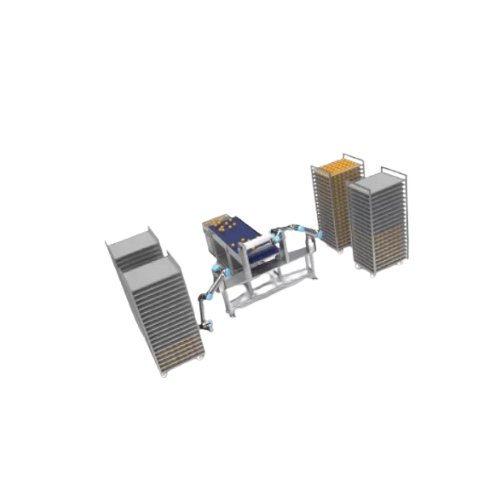

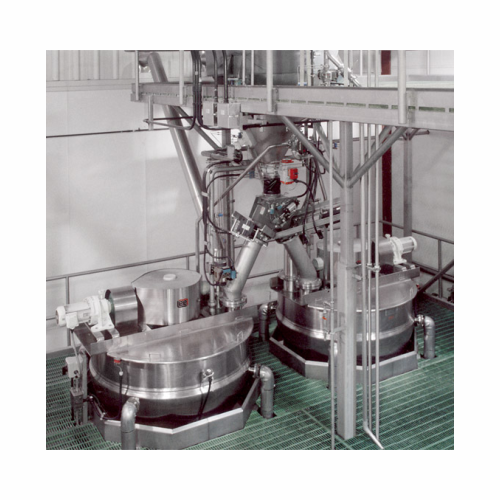

Batch fryers demand greater attention from operators

Batch frying is less commonly used on an industrial scale and used more on a commercial level. Batch fryers are generally used for frying foods, as the name suggests, in batches. The fryer heats up the oil to a specific temperature (powered via gas or electricity) and uses a heat transfer system.

Once the food enters the fryer, the oil temperature decreases and is then brought back to the desired temperature. Oil is constantly withdrawn and returned to the fryer once having passed through an oil filter or filtration system. Generally, batch frying requires more attention and human intervention, which is one of the main reasons why continuous fryers are chosen industrially instead of batch fryers.

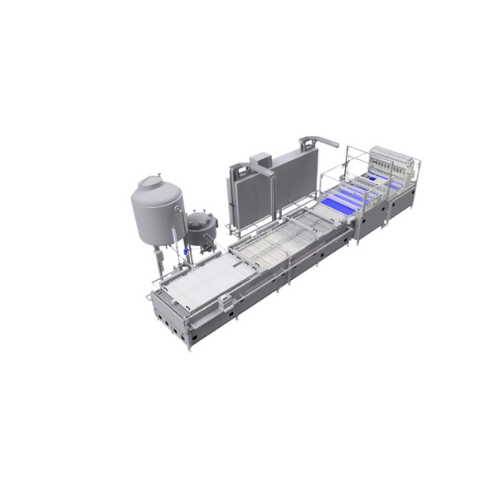

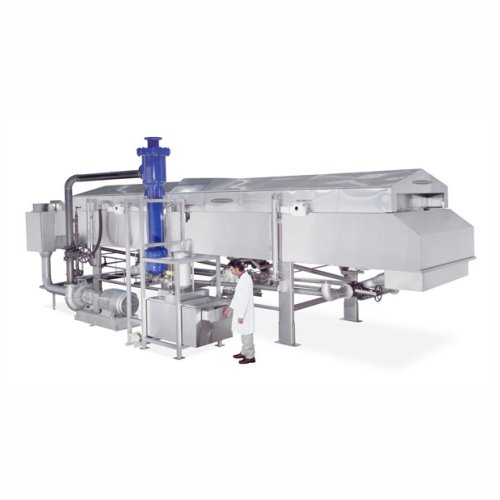

Slow down the conveyor timer to obtain a crispier product in continuous frying

Continuous frying machinery uses a conveyor belt system that moves the food from start to finish continuously through the oil, which is set to a constant temperature. The conveyors’ speed can be set to adjust the time the foodstuff gets fried. A slower conveyor timer will be set for a crispier end product and vice versa.

Continuous fryers offer more control over the frying process as the food gets an even fry that avoids burnt items, thus reducing wastage that leads to increased production costs. Also, they are more energy efficient as they can fry large amounts in little time.

Food-specific vs. automatic industrial frying equipment

Understanding your needs can make choosing industrial frying equipment much more accessible. An important question is, will you need a fryer that can fry all kinds of foods? Or will you need a fryer that fries a specific product? Answering these questions can make choosing the right line as easy as possible.

Automatic fryers handle a broader range of products

If you need industrial frying equipment that can cook various types of food, then an Automatic continuous fryer would be best. These types of fryers can set various heating temperatures for different kinds of foods in different shapes and sizes. If you need versatility, then automatic is the way to go.

Food-Specific industrial frying equipment is designed for consistency throughout production

On the contrary, if you’re focusing on specific foods such as crisps (potato chips), you’ll need a continuous crisp fryer. Or perhaps you’re looking to fry corn-based products such as nacho chips. In this case, you’ll need a corn-specific continuous fryer. Are you making pellet snacks? Then a pellet fryer is what you need. These are food-specific fryers meant for particular products.

What are you making?

Ball donuts

Banana chips

Battered fish fillets

Battered nuts

Battered onion rings

Breaded products

Cassava chips

Chips

Corn Chips

Corn nuts

Crab cakes

Crinkle cut fries

Crisps

Curly fries

Donuts

Dumplings

Egg rolls

Eggs

Fabricated chips

Fast food

Fish

Fish sticks

French fries

Kettle chips

Legume snacks

Lentil chips

Mixed nuts

Mozzarella sticks

Nacho chips

Nuggets

Onion rings

Onions

Pellet snacks

Pork

Potato chips

Potato croquettes

Potato wedges

Potatoes

Poultry

Pringles

Ramen noodles

Ready meals

Samosas

Savoury snacks

Schnitzels

Seaweed snacks

Shrimp crackers

Spring rolls

Sweet potato chips

Sweet potato fries

Taco shells

Tortilla Chips

Tostadas

Vegetable chips

Vegetable Puree

Veggie chips

Which frying technology do you need?

Taco shell frying system

Elevate your taco shell production with a system that ensures consistent shape, vibrant color, and p...

Batch frying system for kettle-style potato chips

Achieve consistent, high-quality kettle-style potato chips with a syste...

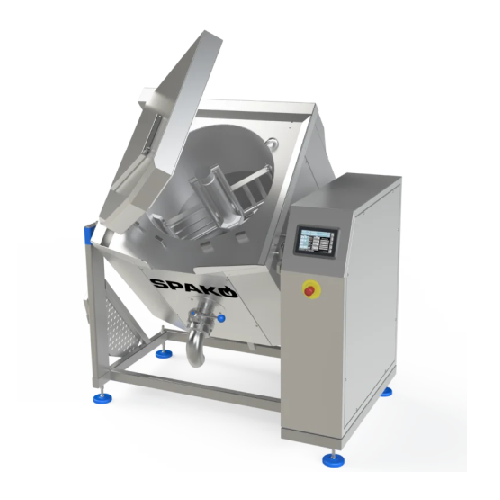

Industrial tilting frying pan for precise roasting and cooking

Achieve uniform cooking and optimal flavor retention with...

Industrial frying system for sauté production

Optimize your culinary production with precise thermal exchange and adjustab...

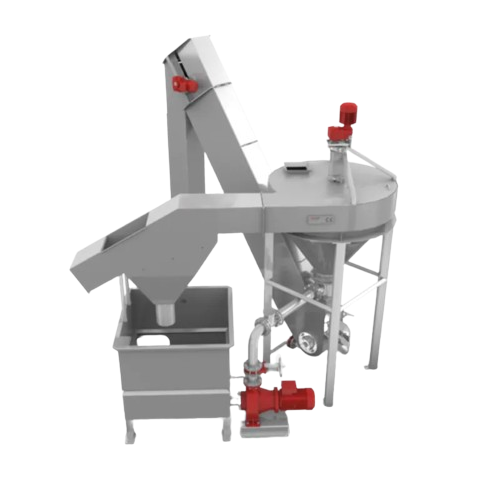

Frying oil management system for food producers

Achieve consistent product quality and minimize frying costs with this sys...

Industrial continuous frying system for donuts and pastries

Achieve artisanal-quality frying with high-volume efficiency...

Custom deep frying system for unique product requirements

For bakeries tackling specialized frying needs, this customiza...

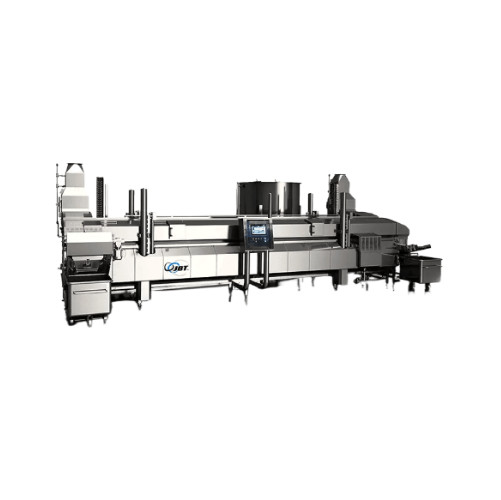

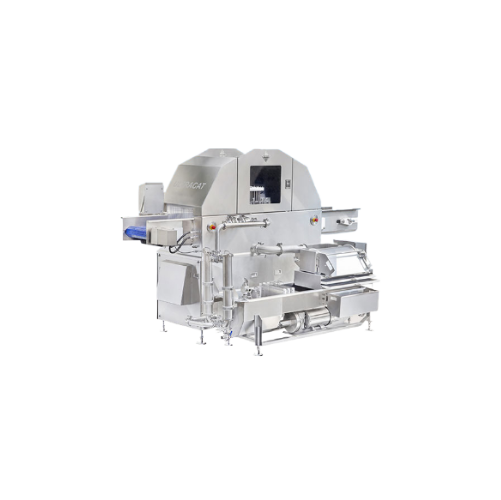

Continuous deep fryer for consistent and efficient frying

Streamline your frying processes with this innovative continuo...

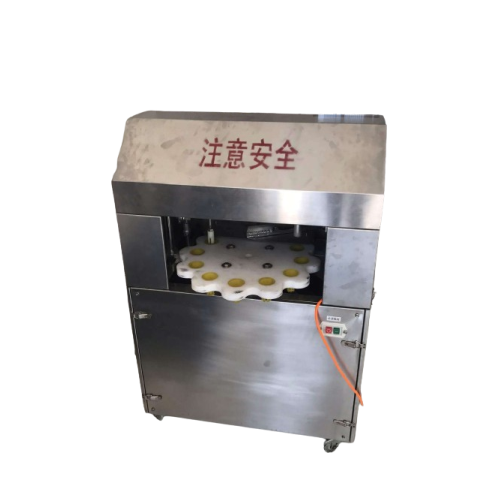

Fully automatic electric heating frying system

Streamline your frying operations with a versatile system that not only sav...

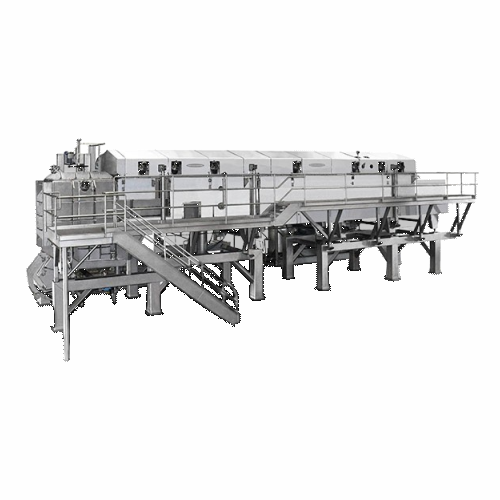

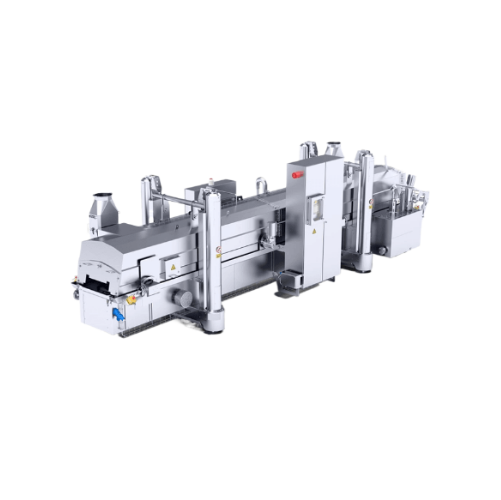

Continuous fryer for high-capacity industrial frying

Achieve consistent high-capacity frying with this continuous mesh be...

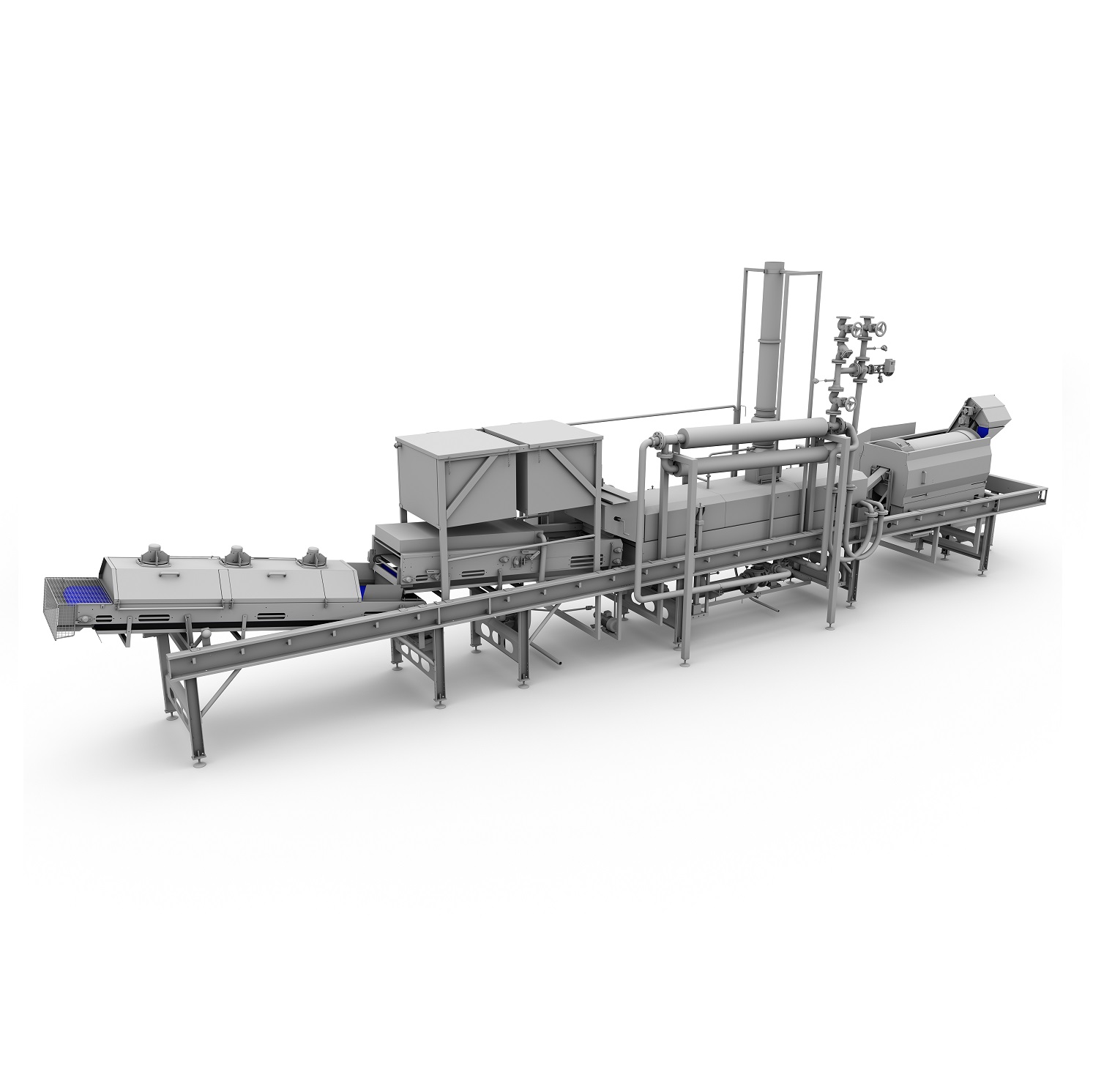

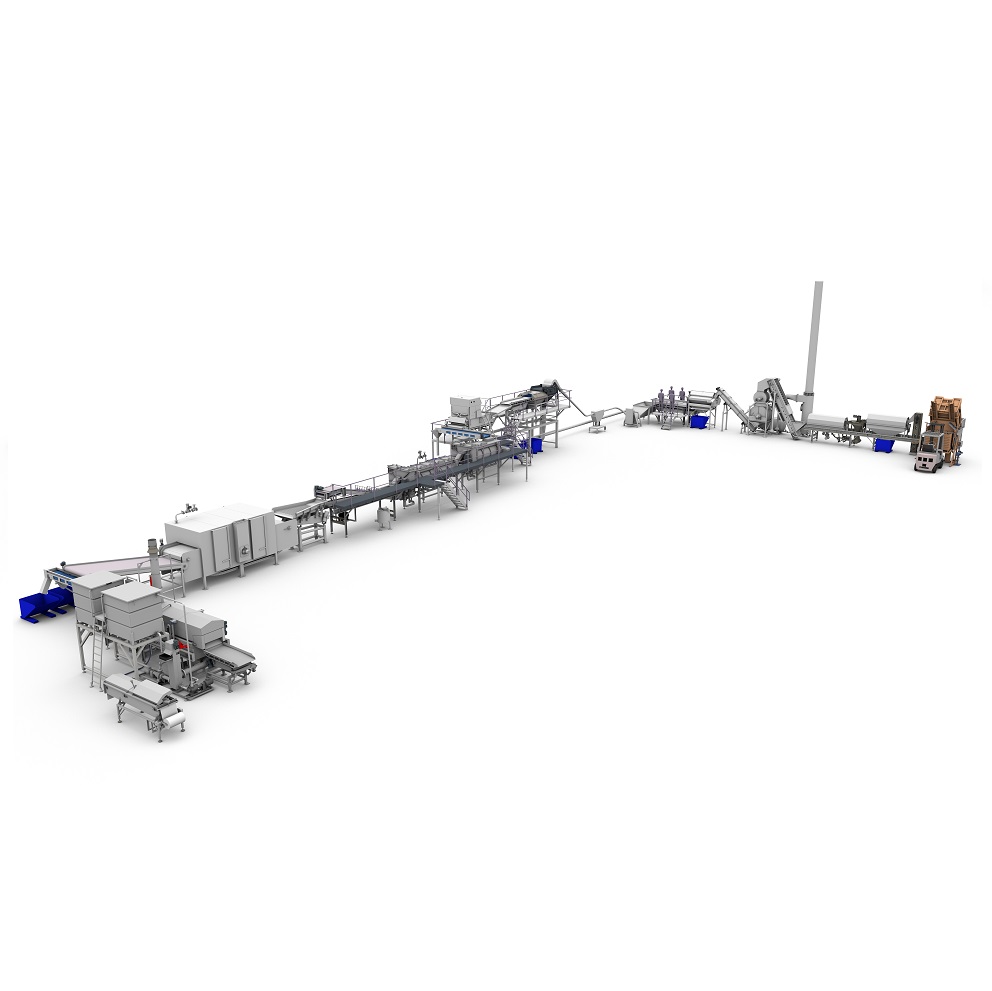

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary a...

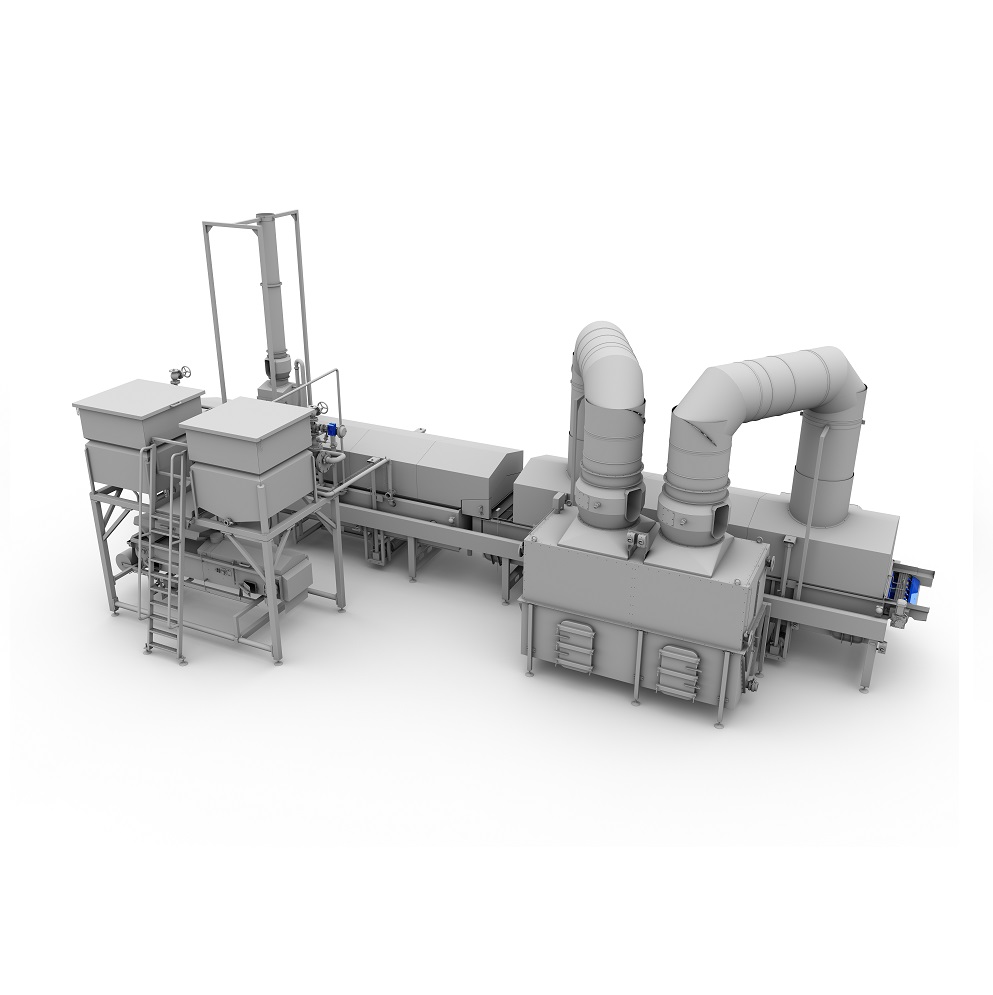

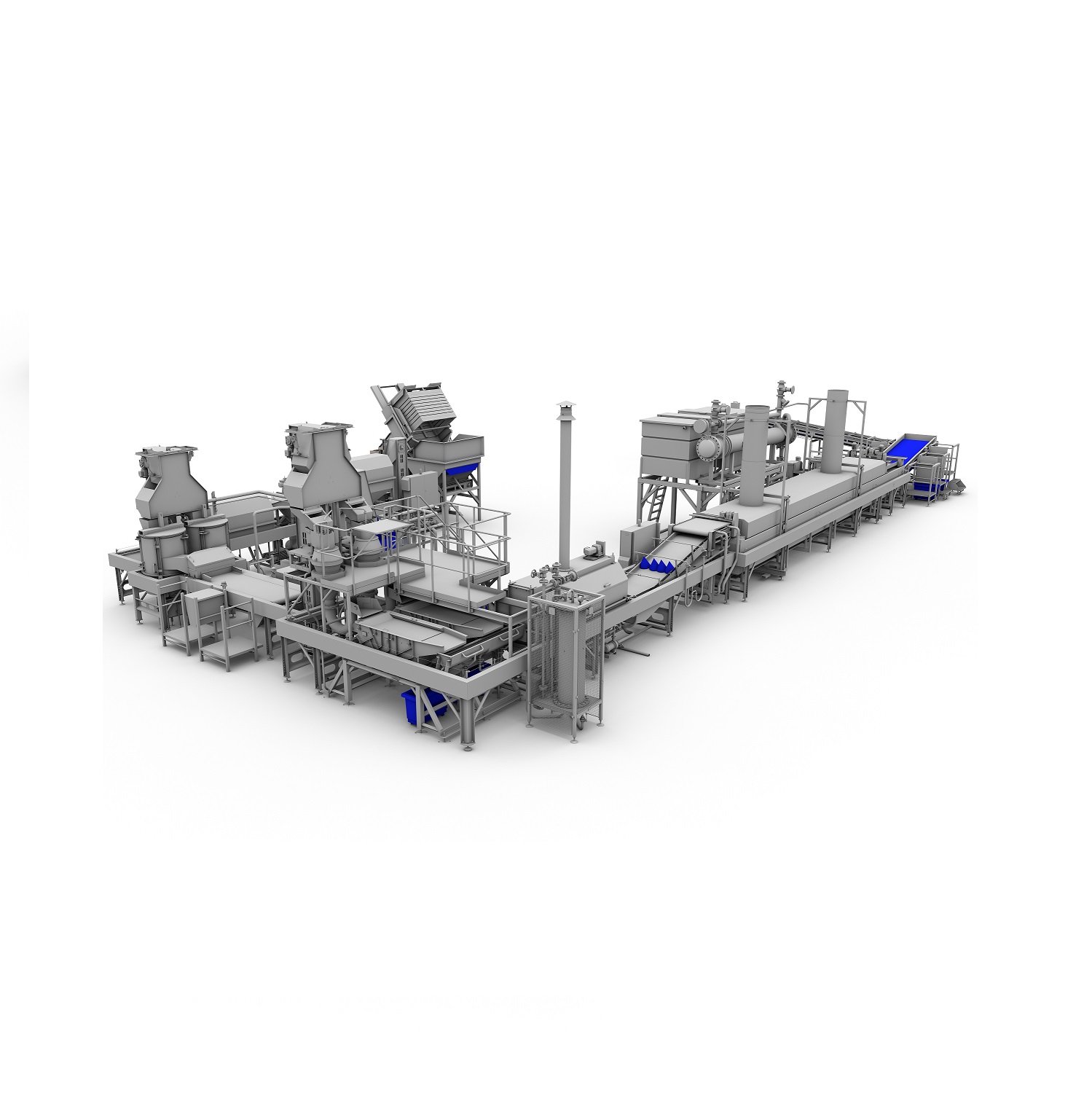

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

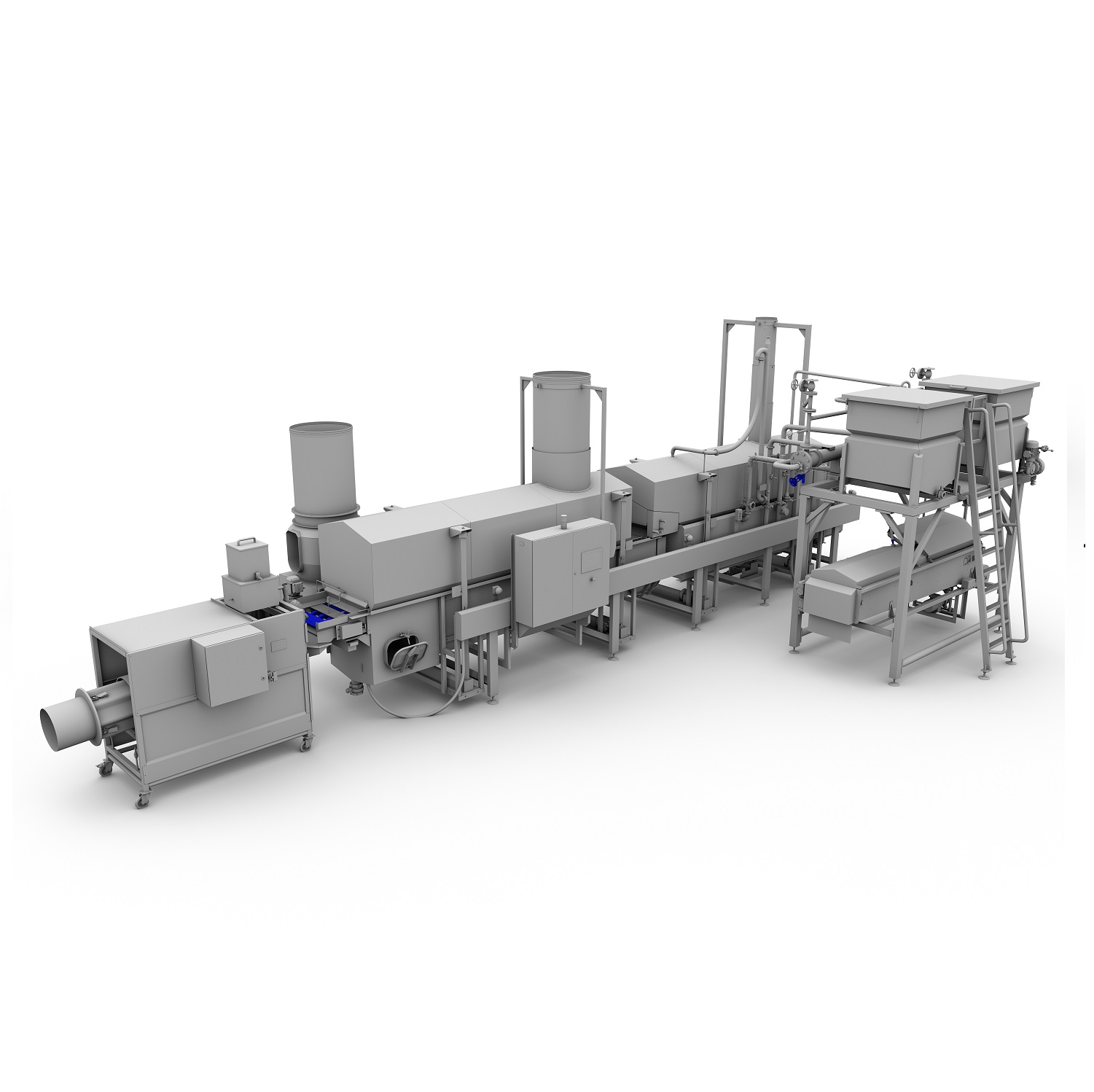

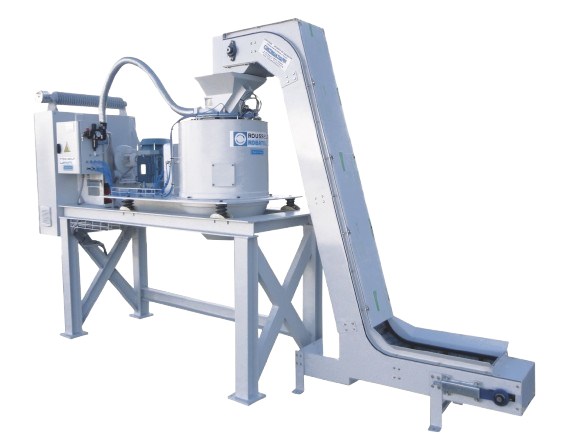

Peanut frying line

Fried peanuts are a very popular snack around the world. If you are looking to start a nut processing plan...

Industrial fryer for uniformly cooked convenience foods

Ensure perfectly fried textures and flavors with cutting-edge oil...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Potato chip production line

Achieve consistent, high-quality potato chips with a seamlessly integrated line that optimizes e...

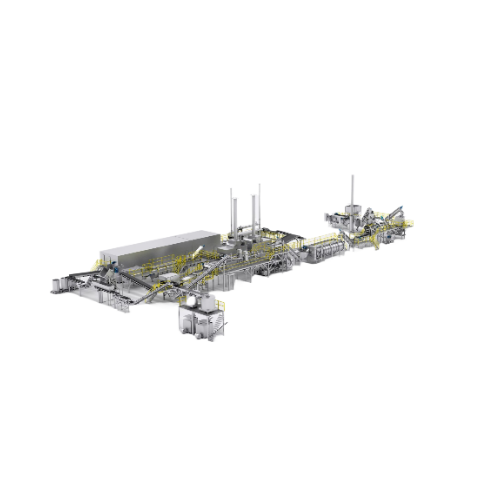

French fry and coated french fry processing line

Optimize every potato’s potential from pre-cleaning to frying with ...

Hash brown production line for formed potato products

Optimize potato processing with this advanced production line, tran...

Kettle chip fryer

Achieve consistent frying results and prevent chip clusters in kettle-style potato chips production with th...

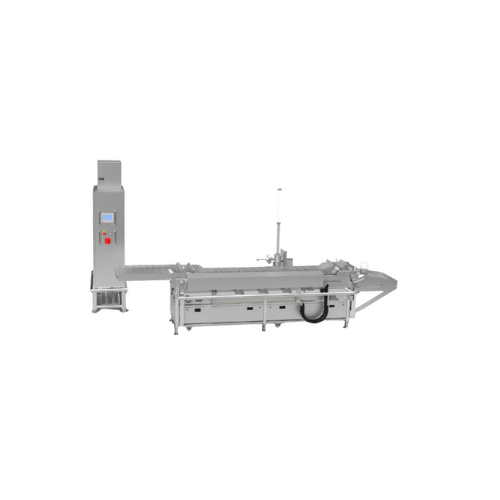

Compact continuous fryer for food service applications

Streamline your frying operations with a compact continuous soluti...

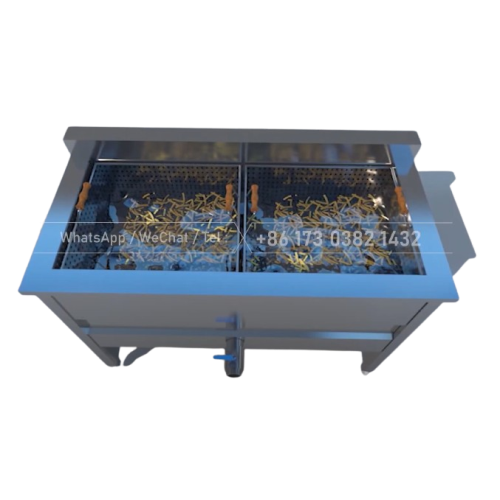

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

Batch fryer for kettle-style potato chips

Achieve uniform kettle-style chips with our compact batch fryer, designed to opt...

Kettle fryer for batch potato chips

Ensure consistent quality and precise frying for your kettle-cooked chips with this the...

Snack food fryer with consistent thermal fluid heating

Achieve uniform frying with precise thermal fluid technology, ensu...

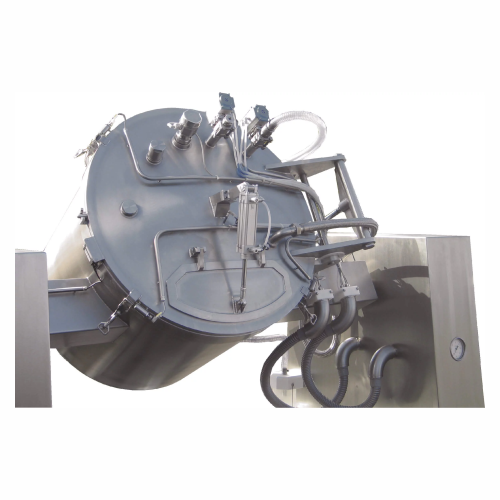

Vacuum fryer for high-sugar snacks

Eliminate the need for an external vacuum chamber while achieving perfect texture and re...

Universal fryer system for snack foods

Optimize your snack production with customizable frying modules that allow precise c...

Industrial pellet fryer for high quality snack production

Optimize your snack production line with precise control over ...

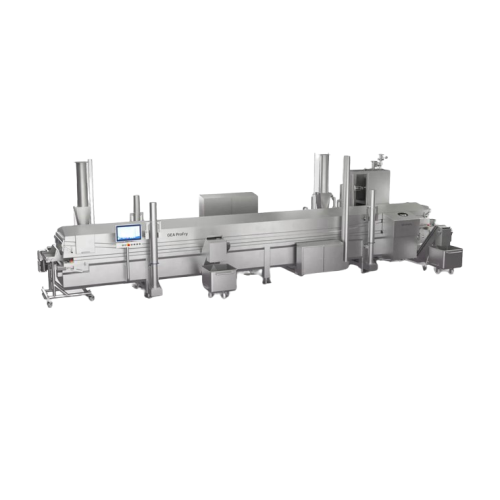

Continuous fryer for prepared foods

Effortlessly achieve uniform frying with precise temperature and conveyor speed control...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Thermal fluid heated fryer for prepared foods

Achieve precise, uniform frying with thermal fluid technology, ensuring each...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Pellet snack fryer

Expand your snack range with precision by frying pellet snacks using a patented process that ensures unifo...

Oil curtain fryer for snack production

Enhance snack quality and shelf life by frying with rapid oil turnover and minimal o...

Flexible fryer for various snack products

Optimize your snack production with a fryer that adapts to varied product requir...

Breaded products fryer

Achieve superior coating preservation and precise frying temperature control with this fryer, designed...

Corn products fryer for tortilla and corn chips

Achieve consistent frying results and enhanced product quality for tortill...

Industrial air fry system for breaded and non-breaded products

Enhance your production with air frying, offering a healt...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

Industrial conveyor fryer for high-volume food production

Optimize frying operations with precision temperature control,...

Laboratory fryer for food product development and small runs

Ideal for perfecting culinary creations, this fryer facilit...

Direct heated immersion fryer for convenience food processing

Achieve superior temperature control and minimize oil cons...

Conveyorized thermal fluid immersion fryer for coated food products

Optimize frying processes with precise heat control...

Industrial fryer for meatballs and vegetarian food

Enhance your production with a versatile industrial fryer that offers ...

Tempura batter applicator for poultry, meat & seafood

Achieve uniform and complete tempura coating with the total immersi...

Industrial fryer for pork, poultry, and seafood

Enhance your production line with a fryer that ensures consistent, high-qu...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Industrial fryer for deep and flash fried foods

Boost your production capacity and product quality with a fryer designed f...

Industrial deep fryer for high-volume donuts

Streamline your high-volume pastry production with an advanced fryer system d...

Continuous deep fryer for industrial production

Optimize your fried product line with precise control over frying time and...

Continuous deep fryer for catering

Achieve consistent frying results while reducing fat absorption and frying time, perfect...

Continuous open kettle fryer for donut production

Effortlessly produce high-quality donuts with precise temperature contr...

Industrial fryer for donuts and ball donuts

Maximize your deep-fried pastry output with precise control over frying condit...

Automatic fryer for producing donuts and ball donuts

Achieve consistent quality in donut production with this compact fry...

Industrial brat pan for ethnic food manufacturing

Enhance your culinary production with a versatile brat pan designed for...

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent...

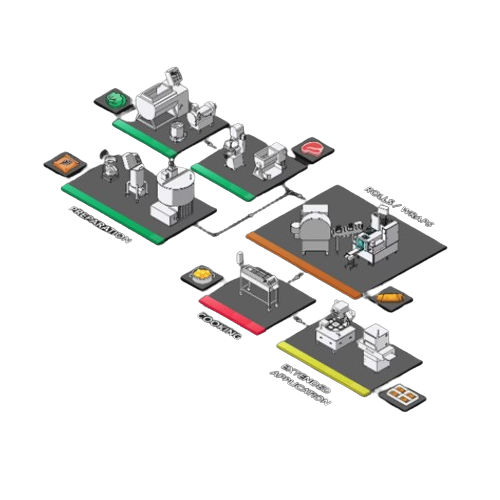

Spring roll manufacturing line

Optimize your spring roll production with an advanced manufacturing line that ensures consist...

Small fryer for fried food processing

Enhance your frying efficiency with an advanced water-oil mixing system that reduces ...

Industrial cereal popcorn making solution

Enhance your snack production with a versatile solution designed for creating a ...

Industrial electric pasta maker

Effortlessly transform basic ingredients into a diverse array of pasta shapes with precision...

Garri processing line

Transform cassava into versatile products like garri and flour with high precision through a seamless p...

Fried food production line

Achieve consistent quality in fried snacks with this integrated production line, streamlining pro...

Semi-automatic frozen french fries production line

Improve efficiency in your production line with a semi-automatic syste...

Chin chin production line for west african fried snacks

Streamline your snack production by automating the entire chin ch...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

Complete banana chips production line

Streamline your snack production with a comprehensive line that transforms raw banana...

Industrial cooking kettle for diverse food processing needs

Optimize your food processing with a versatile kettle design...

Energy recovery unit for potato chips production line

Manufacturers of French fries and potato chips require a lot of ene...

French fries processing line

Mass-producing french fries from raw potatoes requires a series of steps and various equipment ...

Potato chips production line

The key to making a flavorful and crispy bag of potato chips is the frying temperature within t...

Vibratory Centrifuge for Fibrous and Coarse Solids

When processing coal, minerals, pulp, and fibrous plant materials, ach...

Low pressure forming for plant-based products

Achieve precise shape and weight consistency in plant-based products with lo...

Formed mash processing line for potato products

Optimize your potato processing with this versatile line, designed for hig...

Pellet snack production line for industrial use

Streamline your snack production with a versatile pellet snack line that e...

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

Plantain and banana chip fryer

Achieve consistent, high-quality plantain and banana chips with a continuous fryer designed f...

Industrial potato chip fryer

Enhance your snack food production with the Industrial Potato Chip Fryer, expertly designed for...

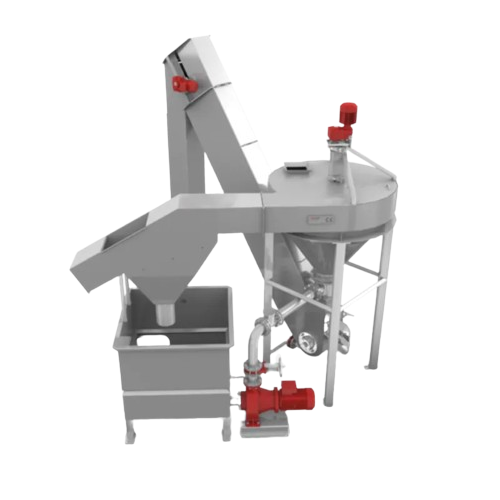

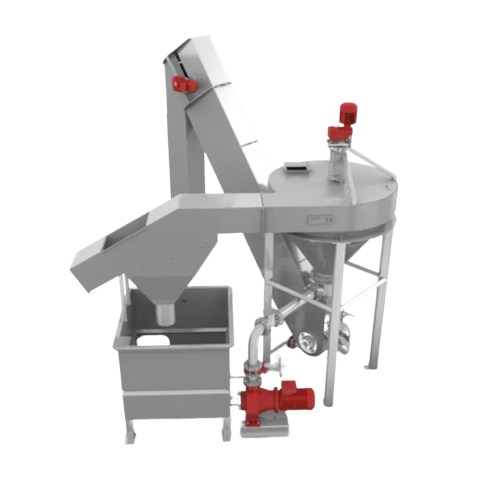

Corn masa preparation system

Efficiently transform dry corn into fresh masa in minutes using a continuous process, eliminati...

Fabricated chip fryer

Achieve uniformity in stackable snack chips with a fryer that precisely controls temperature and oil le...

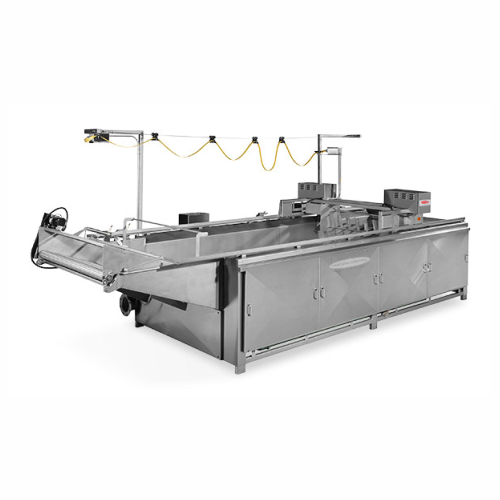

Corn cooking systems for tortilla chips

Achieve precise control over corn cooking and processing for tortilla chips, ensuri...

Vacuum tumblers for food processing

Optimize your production line with vacuum tumblers designed to enhance flavor infusion,...

Industrial mixing and processing plant for demanding products

Enhance your production line with precise mixing and proce...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food text...

Cooked ham steaker

Achieve precise meat texture and uniformity with solutions designed for controlled cutting and pressing. I...

Schnitzel tenderizer with adjustable cutting pressure

For precise meat preparation, equip your production line with a sch...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

Small batch free fall mixer for food industry applications

Efficiently handle diverse ingredient integration for plant-b...

Integrated production system for food processing

Optimize your food production line with this versatile system, designed t...

Meat flattening and levelling system

Optimize your meat production with precise flattening and leveling, achieving consiste...

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

Customized puff pastry production line

Streamline your pastry production process with this customizable solution, capable o...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Automated blini production line

Enhance your food production efficiency with a blini solution that combines precise filling,...

Advanced control system for food processing lines

Streamline your production with a web-enabled interface that allows sea...

Controlled injection system for bone-in or boneless meats

Achieve uniform brine distribution and superior moisture reten...

Small batch deep fryer for bakery demonstrations

Achieve consistently low fat absorption and perfect results for small bat...

Industrial donut fryer for high output and customization

Enhance your donut and pastry production efficiency with a custo...

High-performance donut and ball donut production line

Efficiently produce a wide variety of donuts with precise shape and...

Small scale potato chips production line

Optimize your small-scale snack production with a versatile solution that seamless...

Jujube pitting and nut removing solution

Streamline your fruit processing with this efficient solution designed to remove p...