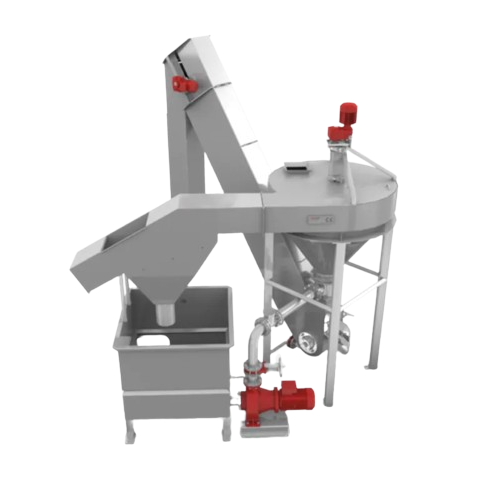

Formed mash processing line for potato products

Optimize your potato processing with this versatile line, designed for high-efficiency conversion of raw potatoes into a variety of formed mash products, ensuring superior product quality and consistency while minimizing waste.

Processes Potatoes into Formed Mash Products

The Formed Mash Line from Kiremko is engineered to seamlessly convert raw potatoes into a variety of formed mash products such as croquettes and rösti rounds. Utilizing an integrated multi-stage system, the process begins with pre-cleaning using cyclone destoners and drum washers, moving through precision steam peeling and cutting using the STRATA Invicta and FAM Tridis™ 240P for optimal size and shape. Following peeling, screw type blanchers and coolers ensure even temperature control for starch retrogradation. High-volume steam cookers efficiently boil the potatoes, which are then mashed and separated by the Hoegger separator to remove any impurities or color defects.

Suitable for potato processing and snack production, the line integrates fully automated operations managed by PLC controls, optimizing throughput up to 70 tons per hour with minimal operator intervention. The EcoMiser™ fryer reduces oil usage and improves energy efficiency, while CIP systems make maintenance straightforward and contamination-free. Kiremko’s equipment is crafted from durable materials like stainless steel with wear-resistant coatings, ensuring longevity in challenging production environments. Customization options are available to align with specific production needs, supported by Kiremko’s engineering expertise.

Benefits

- Enhances production efficiency with integrated, continuous processing from raw ingredient to finished product.

- Lowers energy consumption and operational costs through steam-based cooking and optimized oil recovery systems.

- Offers high throughput capacity, accommodating up to 70 tons per hour, minimizing production bottlenecks.

- Facilitates quick changeover between product forms, reducing downtime and enhancing production flexibility.

- Ensures product consistency and quality by integrating precise temperature control and automated operation.

- Applications

- Hash browns, Formed potato products, Pellet snacks, Potato chips, Potato products, French fries

- End products

- Duchesse potatoes, Steam-peeled potato slices, Mashed potato croquettes, Three-dimensional potato shapes, Diced potatoes for mash, Pommes noisettes, Ribbed potato chips, Potato flakes, Coated french fries, Potato mash snacks, Formed potato waffles, Potato rösti rounds

- Steps before

- Pre-cleaning, Peeling, Cutting and Sizing, Blanching, Cooling, Cooking

- Steps after

- Mashing, Mixing, Forming, Frying

- Input ingredients

- potatoes, water, steam, cutting tools

- Output ingredients

- mash products, formed mashed products, croquettes, potato duchesse, pommes noisettes, fried potato products

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Capacity

- Up to 70 tons per hour

- Material Composition

- Stainless steel and polyurethane

- Automation

- PLC-controlled

- Peeling Accuracy

- Blade thinner than other machines

- Blanching Temperature

- Precise temperature control

- Cooling Temperature

- Retro-gradation to desired specification

- Cooking Method

- Steam Cooker

- Formation Flexibility

- Quick Change Inserts

- Time for Changeover

- 30 minutes

- Frying Technology

- Accurate frying technology

- Oil Recovery

- EcoMiser™

- Dicer Capability

- Tridimensional slicing and dicing

- Working mechanism

- Cyclone destoner, drum washer, steam peeling

- Integrated steps

- Pre-cleaning, Peeling, Cutting, Blanching, Cooking, Mashing, Mixing, Forming, Frying

- Changeover time

- Quick Change Inserts (30 minutes)

- CIP/SIP

- Manual / Automatic Cleaning

- Batch vs. Continuous operation

- Continuous (In-line) Process

- Automation level

- PLC / SCADA controlled

- Cleaning method

- High efficiency, low water consumption

- Energy efficiency

- Designed for low energy consumption

- Size flexibility

- Accommodates various potato sizes

- Reliability

- High durability and efficiency

- Abrasion resistance

- Stainless steel, polyurethane layer

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Suitable for potatoes, free of poor-quality contamination

- Cleanability

- Easy maintenance and cleaning technologies

- Container type

- Potato mash

- Viscosity

- Medium

- End product vulnerability

- High

- Cyclone destoner capacity

- Up to 70 tons per hour

- Material thickness

- 5-mm thick plate steel

- Discharge method

- Ferris wheel, pump system, outfeed screw

- Forming machine features

- 'Quick Change Inserts', adjustable weight

- Integration capabilities

- PLC / SCADA

- Forming tool change

- Quick Change Inserts

- Product weight adjustment

- Adjustable

- Screw type configuration

- Single / Double