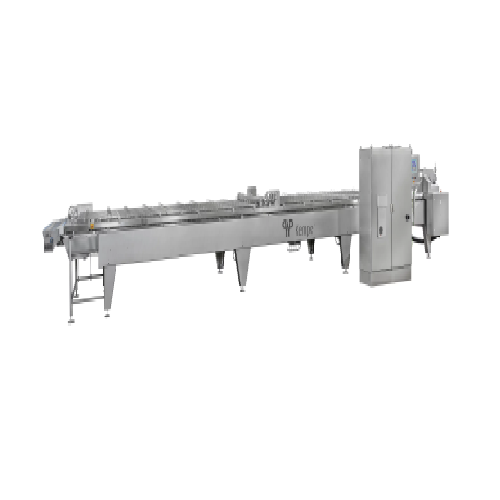

Industrial fryer for donuts and ball donuts

Maximize your deep-fried pastry output with precise control over frying conditions, ensuring consistently high-quality results for a wide range of confectionery delights.

Fires and Transports Donuts Efficiently

The LARGO from WP Kemper is an industrial fryer designed for high-volume donut and pastry production, catering to large-scale bakeries and food processing companies. Its modular configuration allows for flexible integration into existing production lines, efficiently handling capacities of up to 50,400 pieces per hour. LARGO employs a dual heating system, offering either direct heating rods or a thermal oil heat exchanger, promoting precise temperature control through nine independent heating circuits. With built-in automation for decorating, filling, and sugaring, this fryer maximizes throughput while maintaining consistent product quality. Its insulated double-walled design minimizes heat loss, optimizing energy consumption. LARGO is engineered for easy integration, with automated control panels for seamless operation and a user-friendly interface for process adjustments. Cleaning is straightforward due to its elevating baking transport and flat pan base design, reducing downtime and ensuring hygiene standards. Customization options include peripheral stations for varied applications, supported by WP Kemper’s engineering expertise to tailor solutions to specific manufacturing needs.

Benefits

- Enhances production efficiency with automated frying, decorating, and filling, reducing manual intervention.

- Saves energy through double-walled insulation and precise heat distribution.

- Maintains consistent product quality with controlled frying and turning processes.

- Simplifies cleaning processes, minimizing downtime and ensuring hygienic operations.

- Offers customizable configurations to meet specific production requirements, optimizing workflow integration.

- Applications

- French crullers, Local specialities, Long donuts, Ball donuts, Curd balls, Donuts, Cake donuts, Apfelringe

- End products

- Chocolate frosted donuts, Custard-filled long johns, Berliner, Honey-dipped french crullers, Cinnamon sugar donuts, Specialty regional pastries, Bavarian cream-filled donuts, Jelly-filled donuts, Apple fritters, Iced apfelringe, Vanilla cake donuts, Classic glazed donuts, Powdered sugar ball donuts

- Steps before

- Dough preparation, Product shaping, Weight sorting

- Steps after

- Packing, Powder sugaring, Jam filling

- Input ingredients

- dough, frying oil

- Output ingredients

- donuts, ball donuts, curd balls, long donuts, apfelringe, local specialities, french crullers, cake donuts

- Market info

- WP Kemper is known for manufacturing high-quality industrial baking equipment, specializing in mixing, dividing, and dough processing solutions, with a strong reputation for innovation, engineering excellence, and reliable service in the bakery industry.

- Capacity

- 9, 800 - 50, 400 pcs/hour

- Working Width

- 1, 100 mm

- 1,540 mm

- Automation

- Automated decorating modules

- Energy Efficiency

- High energy saving through double-walled insulation

- Heating System

- Electrical heating / Thermal oil heating

- Turning Mechanism

- Turning station / Turning wheel

- Product Transport

- Basket / Bar transport

- Temperature Control

- Multi-heating zone system, up to 9 circuits

- Baking Time

- 100 seconds

- Heating Rods

- Direct heat transfer

- Filtration System

- Integrated filtration, filter systems

- Fat Level Monitoring

- Capacitive altimeter

- Control Interface

- Touch panel control

- Modularity

- Modular and adaptable

- Cleaning Method

- Flat pan base with cleaning outlet

- Product Variety

- Donuts, Ball Donuts, etc.

- Automation level

- Manual / Automated

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Easy cleaning with elevating baking transport

- Energy efficiency

- High, with double-walled insulation

- Heat transfer mechanism

- Efficient with thermal oil / heating rods

- Cleanability

- Easy to clean

- Product Variability

- Donuts, Ball Donuts, Curd Balls

- Machine footprint

- Modular, adaptable

- Basket transport size

- 43 - 83 baskets

- Working width

- 1, 100 mm

- 1,540 mm

- Heating method

- Electrical rods / Thermal oil

- Transport method

- Basket / Bar transport

- Product turning method

- Turning station / Wheel

- Capacity

- Up to 50, 400 pcs/h

- Infeed method

- Height-adjustable conveyor

- Insulation

- Double-walled insulation

- Machine variants

- Basket transport, Bar transport, Heating rods, Frying oil heat exchanger

- Product infeed

- Height-adjustable infeed conveyor

- Control panel type

- Touch panel

- Heating methods

- Electrical heating, Thermal oil heating

- Oil management options

- Automatic fat level monitoring

- Turning station options

- Turning station, Turning wheel

- Insulation

- Double-walled insulation of the pan base and walls

- Optional modules

- Jam filling, Powder sugaring, Depositing station