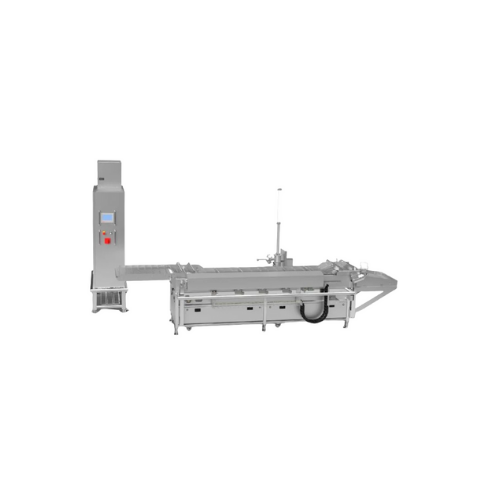

Continuous deep fryer for industrial production

Optimize your fried product line with precise control over frying time and fat absorption, ensuring consistent, high-quality outcomes across various pre-fried and ready-fried items.

Fries, Filters, and Regulates Fried Product Outputs

The DLA Industry Touch from WP Riehle is a versatile continuous open kettle fryer designed for semi-industrial to industrial food production environments. This fryer specializes in submerged deep frying, effectively enhancing throughput and maintaining product quality for diverse applications, such as fries, schnitzel, fried fish, falafel balls, and samosas. The DLA Industry Touch features a configurable design with various input options and an intuitive touch control system, supporting seamless integration into existing production lines. Equipped with a continuous filter system, it minimizes suspended particles, extending the effective life of frying oil and ensuring consistent product quality. The optional hydraulic lifting unit and tool-free transport unit removal facilitate easy cleaning and maintenance. Additionally, the fryer’s sophisticated controls allow for precise regulation of frying time and throughput speed, optimizing energy consumption and product quality. This robust and innovative solution is engineered to meet the demands of food processing companies, industrial food manufacturers, and snack production lines.

Benefits

- Optimizes product quality through reduced frying time and consistent temperature control.

- Extends oil lifespan with continuous filtration, decreasing operational costs.

- Enhances production flexibility with adjustable throughput speeds for varied products.

- Facilitates easy cleaning and maintenance with tool-free transport unit removal.

- Integrates seamlessly into production lines, supporting scalable food processing operations.

- Applications

- Fried products, Snacks, Pre-fried products, Industrial food production, Ready-fried products

- End products

- Fries, Falafel bällchen, Fried fish, Schnitzel, Samosas

- Steps before

- Breading, Preheating

- Steps after

- Cooling, Packaging

- Input ingredients

- raw fries, raw schnitzel, raw fish, raw falafel, raw samosas

- Output ingredients

- pre-fried products, ready-fried fries, ready-fried schnitzel, ready-fried fish, ready-fried falafel, ready-fried samosas

- Market info

- Automation

- Intuitive touch control, PLC-controlled

- Capacity

- Dependent on product and plant size, adjustable throughput

- Cleaning method

- Tool-free removal, hydraulic lifting unit for easy cleaning

- Filtration system

- Continuous filter system with self-cleaning permanent stainless steel filter element

- Frying process

- Submerged deep-frying, digital heating control

- Heating

- Hydraulic lifting for heating unit, digital control

- Input systems

- Various options

- Product Adjustability

- Infinitely adjustable throughput speed and frying time

- Tank capacity

- Optional 200 l refill tank

- Working Mechanism

- Submerged deep-frying

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Hydraulic lifting unit for easy cleaning

- Integrated Steps

- Optional continuous filter system

- Remote Maintenance

- Internet-ready control system

- Frying time adjustment

- Infinitely adjustable throughput speed

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product configurability

- Individually configurable

- Product diversity

- Pre-fried and ready-fried products

- Machine footprint

- Customizable

- Feed/discharge method

- Infeed belt / Cross distribution conveyor

- Tank shape and size

- Not specified

- Control panel type

- Touch control

- Compact footprint

- Individually configurable

- Control panel type

- Touch control

- Integration possibilities

- Connection to breading system

- Input systems

- With/without infeed belt, cross distribution conveyor

- Filter system

- Continuous with self-cleaning stainless steel filter

- Refill tank

- 200 l with automatic level regulation

- Hydraulic lifting unit

- For transport conveyor and heating

- Product-specific adjustments

- Possible