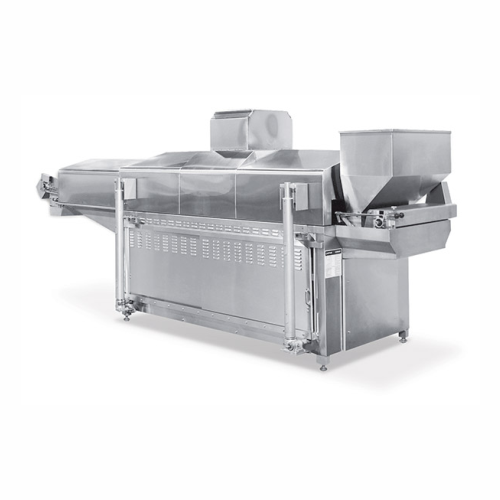

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this continuous fryer, enhancing product quality and shelf life across a wide variety of snack food products.

Frys and Conveys Snack Products Continuously

The Mastermatic Snack Food Fryer from Heat and Control provides an optimal solution for snack food manufacturers aiming for high-quality, continuous frying processes. This equipment stands out with its direct-heated design and multiple heating zones, allowing precise temperature and conveyor speed control, ensuring uniformly cooked snacks. Catering to applications such as tortilla chips, cheese balls, and extruded snack pellets, it guarantees consistent taste and texture across various product types including solid snacks and granules.

Built to handle substantial throughput, this fryer supports seamless integration into existing production lines, offering flexible conveyor designs customizable to your unique needs. Its PLC-controlled system facilitates automation, allowing for efficient operation and remote monitoring. Energy efficiency is enhanced through optimized heating, with low oil volume usage contributing to extended oil life and reduced operating costs.

Constructed from durable materials, the fryer assures longevity and resistance to processing conditions, while compliance with industry standards ensures safe food processing. With options for customization and engineering support, the Mastermatic fryer is designed to meet diverse operational requirements, from small-batch specialty snacks to large-scale commercial productions. Additionally, easy maintenance and cleaning are achievable with its accessible design, minimizing downtime and maximizing productivity.

Benefits

- Enhances product quality through consistent temperature and speed control.

- Increases efficiency with lower energy consumption and oil usage.

- Facilitates diverse snack production with customizable conveyor options.

- Simplifies integration with existing lines due to versatile design.

- Minimizes operational costs with extended oil life and reduced maintenance.

- Applications

- Wheat nuts, Snacks, Pellet snacks, Tortilla chips, Soy nuts, Pork rinds, Noodles, Vegetable snacks, Nuts, Corn chips, Cheese balls

- End products

- Instant noodles, Veggie straws, Roasted almonds, Cheese puffs, Pork cracklings, Extruded snack pellets

- Steps before

- Conveying, Blending, Corn Cooking, Soaking, Corn Milling / Masa Preparation, Cutting, Peeling / Grading

- Steps after

- Product Cooling, Seasoning, Packaging, Weighing

- Input ingredients

- tortilla chips, soy nuts, wheat nuts, corn chips, cheese balls, pork rinds, pellet snacks, vegetable snacks, noodles, dry corn, corn flour, masa flour, raw recipe, pulse, legume snacks, nuts

- Output ingredients

- snack food products, extruded corn chips, sheeted corn chips, cheese puffs, namkeen, green peas, roasted nuts, seasoned nuts, coated nuts, glazed nuts, rice pellets, sea pellets, grain-based pellets, collet snacks, shaped tortilla chips, fresh masa

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Temperature Control

- Multiple heating zones

- Conveyor Speed

- Adjustable

- Oil Volume

- Low

- Fryer Type

- Direct-heated continuous fryer

- Temperature control

- Multiple heating zones

- Oil volume management

- Low oil volume

- Conveyor speed control

- Adjustable per product

- Cooking method

- Direct-heated continuous

- Flexibility

- Suitable for a variety of products

- Customization options

- Custom conveyor designs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Conveyor design

- Standard / Custom

- Heating zones

- Multiple / Adjustable

- Oil volume control

- Low volume

- Temperature control

- Accurate / Precision

- Conveyor speed

- Adjustable / Variable

- Integration possibilities

- Custom options available