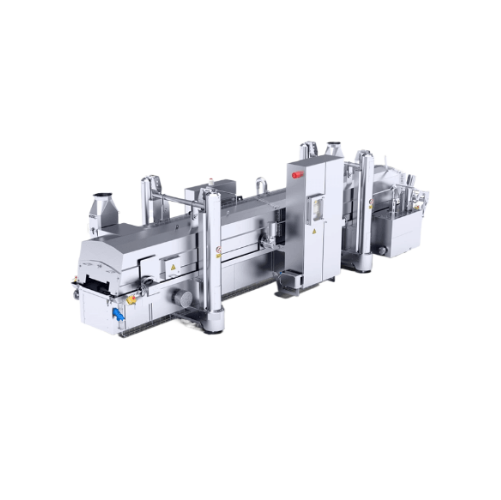

Industrial fryer for meatballs and vegetarian food

Enhance your production with a versatile industrial fryer that offers precise frying control for diverse food types, ensuring optimal texture and flavor with continuous sediment removal for superior quality and cleanliness.

Fryers Perform Flash Frying and Full Cooking

The Alco Fryer AGF ECO & PRO from Alco Food-Machines is engineered to deliver versatile frying and cooking solutions for diverse food processing needs. This fryer operates with flexible settings, allowing you to flash fry or fully cook a range of products, including meatballs, schnitzels, plant-based nuggets, and tempura vegetables. It utilizes a continuous sediment removal system to maintain oil cleanliness, enhancing product quality.

With continuously adjustable belt systems, the fryer accommodates various product types and production speeds, integrating seamlessly into existing production lines. The oil-circulating heat transfer system ensures optimal cooking efficiency, reducing energy consumption compared to conventional fryers. Constructed from stainless steel, the fryer offers durability and resistance to corrosion, while its CIP system supports easy, effective cleaning.

Available in ECO and PRO models, the former offers a space-efficient design for lower output requirements, while the latter suits high-capacity operations. Both models support precise temperature and speed controls, and the fryer’s design allows customization to fit specific line requirements, ensuring adaptability across food processing industries.

Benefits

- Increases product consistency with precise temperature control.

- Minimizes oil waste through continuous sediment removal.

- Enhances production flexibility with adjustable operation modes.

- Saves space with compact design in ECO model.

- Integrates seamlessly into current production lines with standard-coordinated belt widths.

- Applications

- Seafood, Ready meals, Meat, Fruits, Plant-based food, Nuts, Vegetables, Poultry

- End products

- Falafel, Hash browns, Meatballs, Fruit fritters, Tempura vegetables, Plant-based nuggets, Pre-cooked ready meals, Schnitzel, Nut-coated snacks, Breaded seafood

- Steps before

- Cutting, Preparation, Portioning

- Steps after

- Cooling, Packaging, Coating

- Input ingredients

- meat, vegetarian food, hash browns, falafel, meatballs, schnitzel, plant-based food, vegetables

- Output ingredients

- cooked meatballs, cooked schnitzel, cooked falafel, cooked hash browns, cooked plant-based food, cooked vegetables

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Belt system

- Different for upper and lower adjustment

- Material

- Stainless steel geared motors

- Continuous sediment removal

- Yes

- Belt gap

- Continuously adjustable

- Process temperature

- Continuously adjustable

- Dirt transport system

- For separating sediment

- Heat transfer

- Optimal through oil circulation

- Production speed

- Continuously adjustable

- Belt widths

- Market-standard-coordinated

- Vapor barrier system

- Sealing between oil tub and hood

- Heating elements

- Electrical or thermal oil-powered

- Exhaust chimney system

- Prefiltering option

- Cross-dirt transport

- Removes dirt particles early

- CIP cleaning system

- Preconnected automatic emptying

- Model series

- PRO and ECO

- Hourly output

- High (PRO series)

- Space saving design

- Compact (ECO series)

- Working mechanism

- Flexible frying settings for flash frying or full cooking

- Automation level

- Manual / PLC controlled

- CIP/SIP

- Complete cleaning system with automatic emptying

- Energy efficiency

- Top-performance heating elements ensure efficient heat transfer

- Batch vs. continuous operation

- Continuous

- Integrated steps

- Sediment removal and oil circulation for high-quality products

- Abrasion resistance

- High resistance

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Cleanability

- Yes, suitable for easy cleaning

- Biological compatibility

- Food grade materials used

- Suitable products

- Meatballs, schnitzel, falafel, hash browns, plant-based food, vegetables

- Footprint

- Compact space-saving design

- Belt width

- Market-standard-coordinated for line integration

- Belt systems

- Different types for optimal product adjustment

- Heating elements

- Electrical / Thermal oil-powered

- Exhaust system

- Stainless steel chimney pipes with filter

- Oil tub and hood insulation

- Fully insulated with vapor barrier sealing

- Belt width customization

- Market-standard-coordinated

- Heating element type

- Electrical / Thermal oil-powered

- Belt system type

- Different belt systems available

- Exhaust system configuration

- Exhaust chimney with filter