Jujube pitting and nut removing solution

Streamline your fruit processing with this efficient solution designed to remove pits and nuts from jujubes, cherries, and dates, ensuring minimal waste and high-quality end products like snacks and jams.

Pits and Processes Jujubes and Cherries

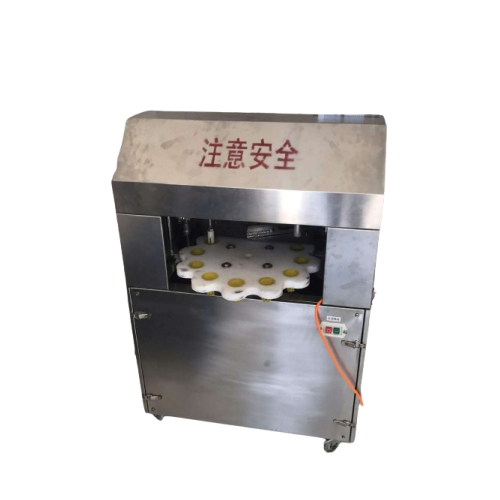

The TZ-3 Series from Taizy Machinery offers a comprehensive solution for efficient jujube and cherry processing. Utilizing a fully automatic pitting mechanism, it ensures minimal pulp wastage with a peeling rate up to 99.9%, catering to diverse needs with models like TZ-3A to TZ-3D, handling 75-200 kg/h. Its stainless steel construction meets food industry standards, offering durability and easy maintenance. Ideal for food processing lines, it excels in applications like making dried jujube snacks, cherry jam, and date paste. Tailored for seamless integration, this machine provides customizable options to accommodate various fruit sizes.

Benefits

- Enhances production efficiency with high throughput and low damage rate.

- Minimizes waste through a superior 99.9% peeling rate, conserving valuable pulp.

- Reduces labor costs via fully automated operation.

- Provides flexible processing with customizable settings for different fruit sizes.

- Ensures durability and food safety with stainless steel construction.

- Applications

- Nut processing, Fruit processing, Date processing, Cherry processing, Olive processing, Jujube processing, Vegetable processing

- End products

- Dried jujube snacks, Jujube granola bars, Jujube wine, Cherry pie filling, Date paste, Olive tapenade, Cherry jam, Date syrup, Olive oil base for skincare, Nut butter

- Steps before

- Jujube grading, Jujube cleaning, Drying

- Steps after

- Jujube splitting, Packing

- Input ingredients

- raw jujubes, dried dates, dates, olives, cherries

- Output ingredients

- pitted jujubes, pitted dates, pitted olives, pitted cherries, jujubes with removed pits, sliced jujubes

- Market info

- Taizy Food Machinery is known for manufacturing industrial food processing equipment, specializing in engineered-to-order (ETO) machinery. They have a reputation for innovative, high-quality solutions tailored to meet various customer specifications globally.

- Power

- 1.5kw

- Capacity

- 75-200kg/h

- Peeling rate

- 99.9%

- Residual nuclear rate

- ≤2%

- Adaptation (jujube diameter)

- 12-20mm

- Automation

- Fully automatic

- Material

- Stainless steel

- Working mechanism

- Automatic pitting

- Peeling rate

- 99.9%

- Changeover flexibility

- Customizable diameter 12-20mm

- Batch vs. continuous operation

- Batch

- Automation level

- Fully Automatic

- Energy efficiency

- Low damage rate and power use (1.5kw)

- Abrasion Resistance

- High

- Biological compatibility

- Suitable for food processing

- Cleanability

- Stainless steel construction

- Corrosive resistance (e.g. acids)

- Good

- Food Grade Stainless Steel

- Yes

- FDA materials

- Yes

- Machine Footprint

- Compact

- Material of Construction

- Stainless Steel

- Feed/Discharge Method

- Automatic Feed

- Customizable Features

- Yes, Diameter Customization

- Component Material

- Food Grade Stainless Steel

- Design

- Fully Automatic

- Model Sizes

- TZ-3A to TZ-3D

- Adaptation Range

- 12-20 mm Diameter

- Material

- Stainless steel / Full stainless steel