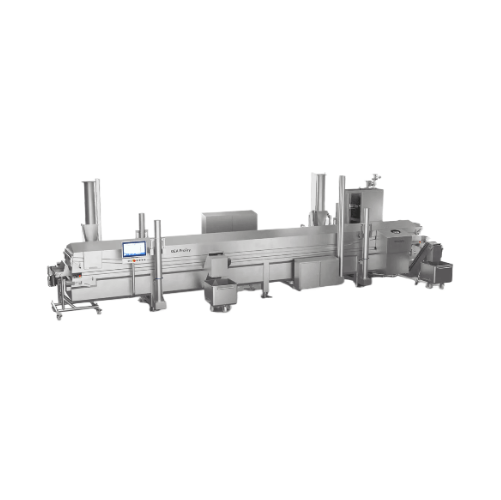

Industrial fryer for deep and flash fried foods

Boost your production capacity and product quality with a fryer designed for seamless integration into continuous, high-speed processing lines, offering precise oil quality control and enhanced sediment removal to optimize deep and flash frying processes.

Optimizes Frying and Enhances Product Quality

The GEA ProFry industrial fryer from GEA Group is engineered to enhance the frying process for food processing companies. Featuring a 30% increase in oil flow and real-time inline oil quality measurement, it ensures superior frying results. The ProFry is suitable for a diverse range of food applications including pork, poultry, seafood, and plant-based products, delivering uniform heating for end-products like tempura coated pork strips and crumb coated chicken schnitzel.

Designed for continuous high-speed operations, the ProFry supports thermal and electrical versions, such as the 650 and 1050 models, which accommodate varying throughput demands. Its SmartControl HMI offers an intuitive interface with customizable user settings for seamless integration and production continuity. The fryer utilizes an advanced oil circulation system and a patented sediment removal solution, extending oil lifespan and reducing waste.

This system is resource-efficient, with excellent hood and kettle insulation, and accurate temperature control, optimizing energy use. The integrated CIP system ensures up to 25% faster cleaning with minimal water and cleaning agents. Available in various lengths, the GEA ProFry offers engineering support for tailored configurations to meet specific production needs, making it an invaluable asset for food and beverage manufacturers focused on quality and efficiency.

Benefits

- Increases production capacity by 15% while maintaining high product quality.

- Enhances profitability by optimizing oil usage with online, real-time quality checks.

- Reduces operational waste with efficient sediment removal and oil circulation systems.

- Saves energy with optimized heat transfer and precise temperature control.

- Simplifies data management and operation with SmartControl HMI for improved process oversight.

- Applications

- Seafood, Pork, Plant-based products, Vegetables, Poultry

- End products

- Flour coated chicken wings, Crumb coated chicken schnitzel, Crumb coated fried fish, Battered vegetable tempura, Battered fish fillets, Tempura coated pork strips, Plant-based chicken nuggets, Home style chicken tenders, Coated fried onion rings

- Steps before

- Battering, Breading, Pre-dusting

- Steps after

- Cooling, Freezing, Packing

- Input ingredients

- pork, poultry, seafood, vegetables, plant-based products, tempura coated nuggets, crumb coated schnitzel, flour coated wings, home style tenders, coated fried fish, coated fried onion rings

- Output ingredients

- flash fried food products, deep fried food products, tempura nuggets, crumb schnitzel, flour wings, home style tenders, fried fish, fried onion rings

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Oil Flow Increase

- 30%

- Capacity Increase

- 15%

- Fryer Length

- 5m - 11m (ProFry 650), 6m - 11m (ProFry 1050)

- Automation Type

- SmartControl HMI, personalized operator interface

- Oil Quality Measurement

- Real-time inline (patent pending)

- Cleaning Efficiency

- Up to 25% faster cleaning

- Sediment Removal System

- Enhanced active sediment removal with frequency-driven drives

- Scraper Belt Position

- 1/3 along the fryer

- Screen Filter

- Slotted screen filter

- Screen Size

- 21.5” multi-touch

- Automation level

- SmartControl HMI

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Energy efficiency

- Resource efficient

- In-line oil quality checks

- Real-time, patented system

- Oil flow enhancement

- 30% more oil flow

- Sediment removal system

- Frequency-driven, adaptive

- User interface

- 21” multi-touch screen

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fried Product Types

- Pork, poultry, seafood, vegetables, plant-based

- Footprint size

- Compact

- Fryer length

- 5m - 11m

- Fryer type

- Thermal / Electrical

- SmartControl HMI screen size

- 21.5” multi-touch

- Hood and kettle insulation

- Efficient

- Kettle feature

- Excellent insulation

- Conveyor construction

- Special surface treatment

- Infeed belt material

- Teflon

- Discharge method

- Crosswise scraper belt system

- Control panel type

- SmartControl HMI

- Integration possibilities

- GEA SmartControl HMI with customizable display and alarm handling

- Operating platform

- 21.5" multi-touch screen

- Data export capabilities

- Easy-to-export production data

- User experience

- Personalized and simplified interface