Making Battered Nuts

Find innovative production technology for making battered nuts and connect directly with world-leading specialists

Battered nuts, also known as cracker nuts or Japanese style peanuts, are a variation of peanut snack products. The general manufacturing process includes peeling and slicing the peanuts, coating these with batter and seasoning, frying in oil, cooling, and packing, ready for consumption.

Select your battered nuts process

Tell us about your production challenge

Fried coat of battered nuts

Flavor development of battered nuts starts with the coating process. You coat battered nuts in flavor-infused batter, done through either dipping or dosing. The choice depends on how well your flavors adhere to the nuts. Complete submersion of the nuts in batter or tumbling these through a drum cylinder ensures even application of the coating. Although coating usually comes before industrial frying, you may also add other flavors after frying, such as savory powders, to improve your product’s taste.

The coated nuts are then subjected to frying or cooking. The conventional method for cooking the nuts is through deep frying. Conveyor-type deep fryers are essential for continuous systems of battered nuts production to prevent delays in the production process. However, you may use other alternatives to produce healthier battered nuts, such as dry roasting, or using healthier oils, such as coconut oil.

Coats for all seasons

The core process for developing the flavor of your battered nuts is in the seasoning and coating process. When and how you infuse and establish your desired flavor greatly affects your final product profile.

Important factors to consider when seasoning and coating peanuts include the flavor retention of the seasoning after frying and the evenness of the coating. If the seasoning is infused in the batter which will be subjected to frying, you must ensure that your flavors are thermally stable such that these are not destroyed nor produce off-flavors. Choose to add your flavors before or after heating the battered nuts depending on your seasoning properties and final product profile. You can add volatile flavors, such as citric acid, after frying, to retain their taste. On the other hand, add flavors for caramelization before the frying process since their tastes develop during heating.

Different coatings all over the world

Manufacturers use various coatings for battered nuts around the world to design their products. Some examples include glazing oil, water, spices, chocolate, and even yogurt.

Regardless of coating, you must evaluate the effective method of coating, how it adheres to the nuts, how it develops during thermal treatment, and if it reacts with your other additional seasonings. For example, enrobing machines are a good match for nuts with sugar-based flavors since these can evenly coat your nuts before frying. If you are making savory dry-roasted nuts, you will require an oil dosing machine placed prior to the flavoring coating process to ensure your flavor sticks. For example, making salted peanuts would follow this process. Experiment on what works for you to better assess the sequence of steps in your production process and what technologies you will need to implement the process well.

Processing steps involved in battered nuts making

Which battered nuts technology do you need?

Portioning system for small and medium-sized meat slices

Achieve precise meat portioning with volumetric forming, optimiz...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Continuous paper filter for frying oil

Ensure oil clarity and enhance product quality by continuously removing ultra-fine p...

Oil curtain fryer for snack production

Enhance snack quality and shelf life by frying with rapid oil turnover and minimal o...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Conveyorized thermal fluid immersion fryer for coated food products

Optimize frying processes with precise heat control...

Breading applicator for high-volume poultry processing

Achieve uniform coating with precision hydraulics, ensuring every ...

Flexible battering system for food production

Optimize your coated product output with a flexible battering solution that ...

Servo driven multi-piston depositor for batters and fillings

Ensure precise portion control and maintain product integri...

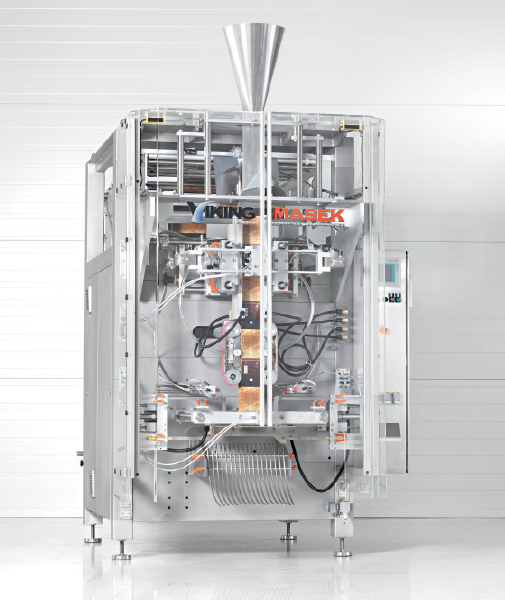

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

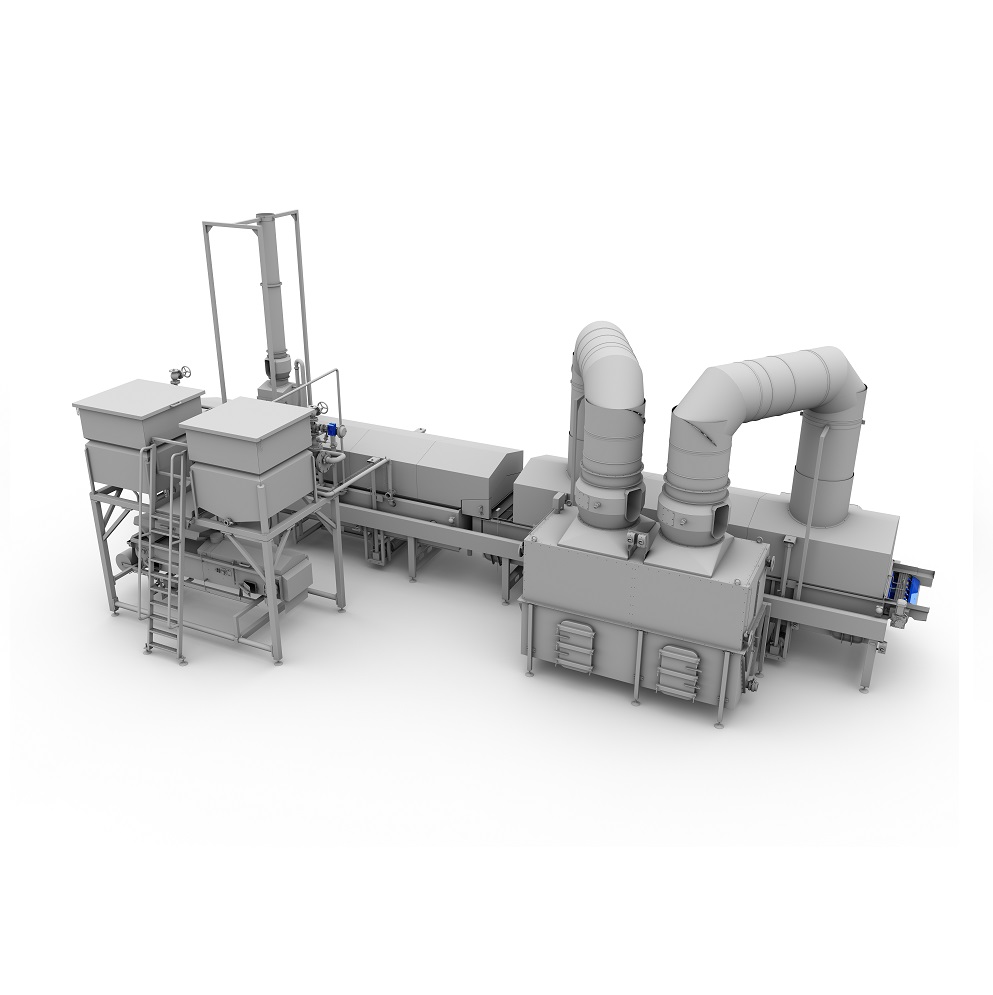

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

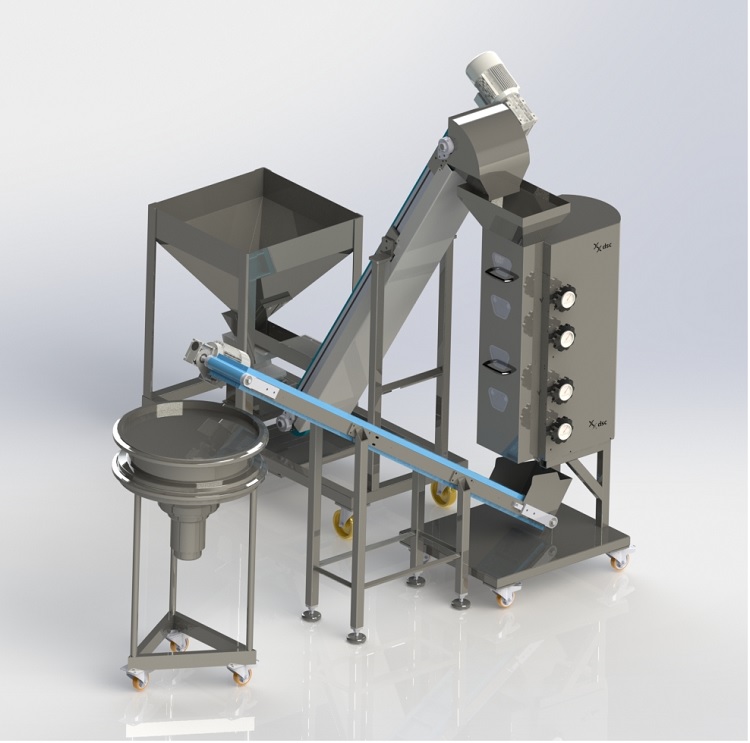

Mixing system for batter and cream

When making a cake, the proper mixing of liquid batter is critical to ensuring it looks ...

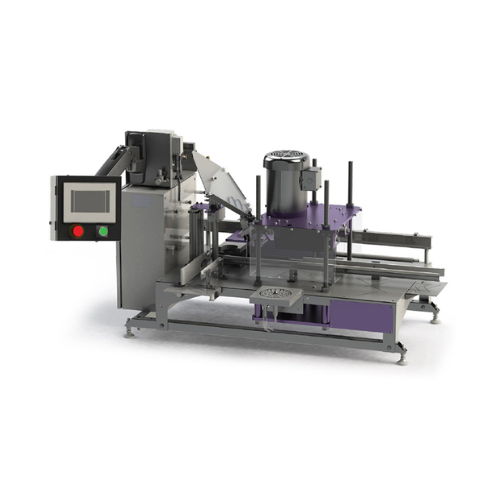

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...