Peanut Processing Equipment

Find innovative production technology for making peanuts and connect directly with world-leading specialists

Peanuts, also known as groundnuts are one of the most popular edible seeds in the world. You can eat them as-is or process them further into on-the-shelf products like peanut butter, oil, snacks, and soups. Depending on what you want to make, some peanut manufacturing processes include roasting, frying, boiling, grinding, pressing, and coating the peanuts.

Select your peanuts process

Tell us about your production challenge

Different peanuts for making different products

You make fried peanuts by deep-frying the raw peanuts in oil until they just begin to turn brown. You then sieve the fried peanuts to remove the excess oil and sprinkle some salt to taste.

When producing fried peanuts, you should consider the type of oil you want to use, your production volume, and the particular peanut strain to determine the best production technology for your needs. It will vary because each peanut type – runner, Virginia, Spanish, and Valencia – can deliver different peanut products. You can get peanut butter from runner peanuts, and snacks and roasted peanuts from the larger Virginia peanuts, The sweet Valencia peanuts are good for boiled peanuts and homemade peanut butter. Finally, the versatile Spanish peanuts is the best for peanut oil production.

Matters of the heart: what oil to choose

The most common oils for deep-frying peanuts are peanut oil itself, soybean oil, canola oil, coconut oil, and olive oil. The ideal oils should have a high concentration of monounsaturated and saturated fats, and a low concentration of polyunsaturated fats.

Peanut oil is excellent for deep frying and blends with the taste of peanuts. It, however, contains a relatively high amount of polyunsaturated fats. Soybean oil is also a good choice to fry peanuts as it doesn’t alter their flavor. It also contains a high level of polyunsaturated fats, though. Olive oil and coconut oil are considered the healthiest oils with ideal concentrations of heart-healthy fats. They are great alternatives to peanut oil but are relatively more expensive. Having said that, peanuts are said to improve our hearts longevity according to this study.

An extra layer of tasty: salty, sweet, and other peanuts

Peanut processing can result in salty peanuts, sweet peanuts, and other flavors. To do that, you soak or coat the peanuts raw or cooked in different solutions to allow the flavor to seep in. Salty or salted peanuts are soaked or cooked in a salty solution. Sweet peanuts are made by coating the peas in sugar or a sweetener like caramel. Equipment like a coating machine ensures uniformly and consistently coated peanuts.

When making sweet peanuts…

For sweet peanuts, it is ideal to roast the peanuts before coating them in the melted sugar or sweetener to reduce the chances of them getting burnt. Also, take care that the sugar doesn’t caramelize (become brown) before putting the peanuts in.

You can spice your salty or sweet peanuts with other flavors like cinnamon and nutmeg. Another popular peanut snack is a peanut burger. This is made by coating the roasted peanuts in dough and then oven-baking them to add a crunchy layer to the peanuts.

Peanut Processing 101: aflatoxin levels

One important criterion to consider when making peanuts or peanut products is the aflatoxin levels. Aflatoxins are toxic compounds that can cause disease in humans and animals and are common in peanuts and other food products.

Aflatoxins cannot be completely destroyed by heat treatment or during processing. You must have testing equipment to ensure the aflatoxin levels in your raw peanuts are within safe limits as specified by the regulations before moving forward with any other manufacturing process. You must also specify on your products that peanuts can cause allergies.

Food processing involves many different steps and processing machinery. The same is true for peanut and groundnut processing. Peanuts go through various processing equipment to reach the end consumer. For successful production, specialized peanut processors are used to make this as automated as possible. First, the peanuts are procured from the ground.

After which, they run through separation equipment to remove unwanted particles such as soil remnants and dust particles. Then, the peanuts enter a shelling machine to remove their shells. Once de-shelling has occurred, the peanuts can now enter a gravity separator to get rid of further impurities or left over shells. Separation effectiveness is key to ensuring a quality final product.

The penultimate step is putting the peanuts through a grading machine that separates them according to weight. Finally, further separation occurs after this whereby the nuts are split up by size. If you’re looking to make nut butter then additional equipment and processing will need to take place.

Processing steps involved in peanuts making

Which peanuts technology do you need?

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

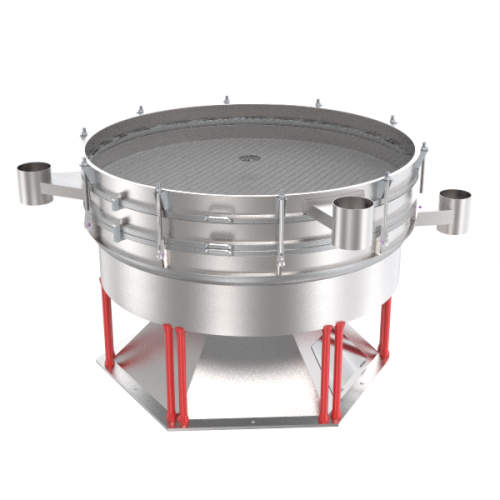

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

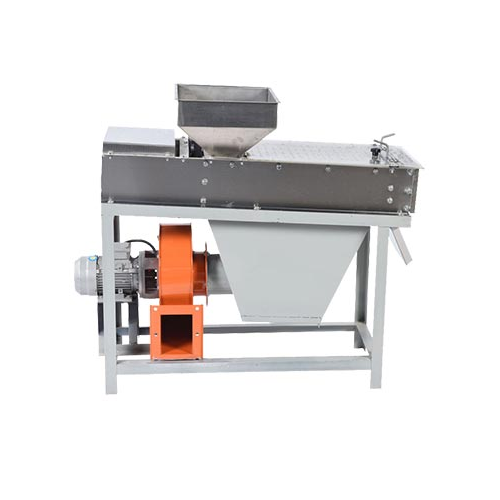

Peanut peeler for efficient skin removal

Ensure consistent peanut quality by efficiently removing skins with adjustable-spe...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

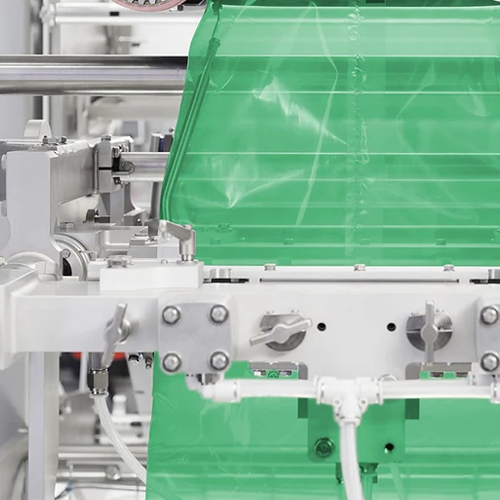

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

In-line seal checker for high-speed snack packaging

Ensure flawless package integrity with in-line leak detection, enhanc...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

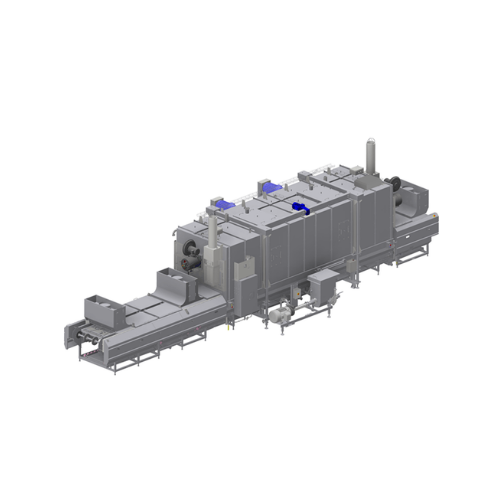

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

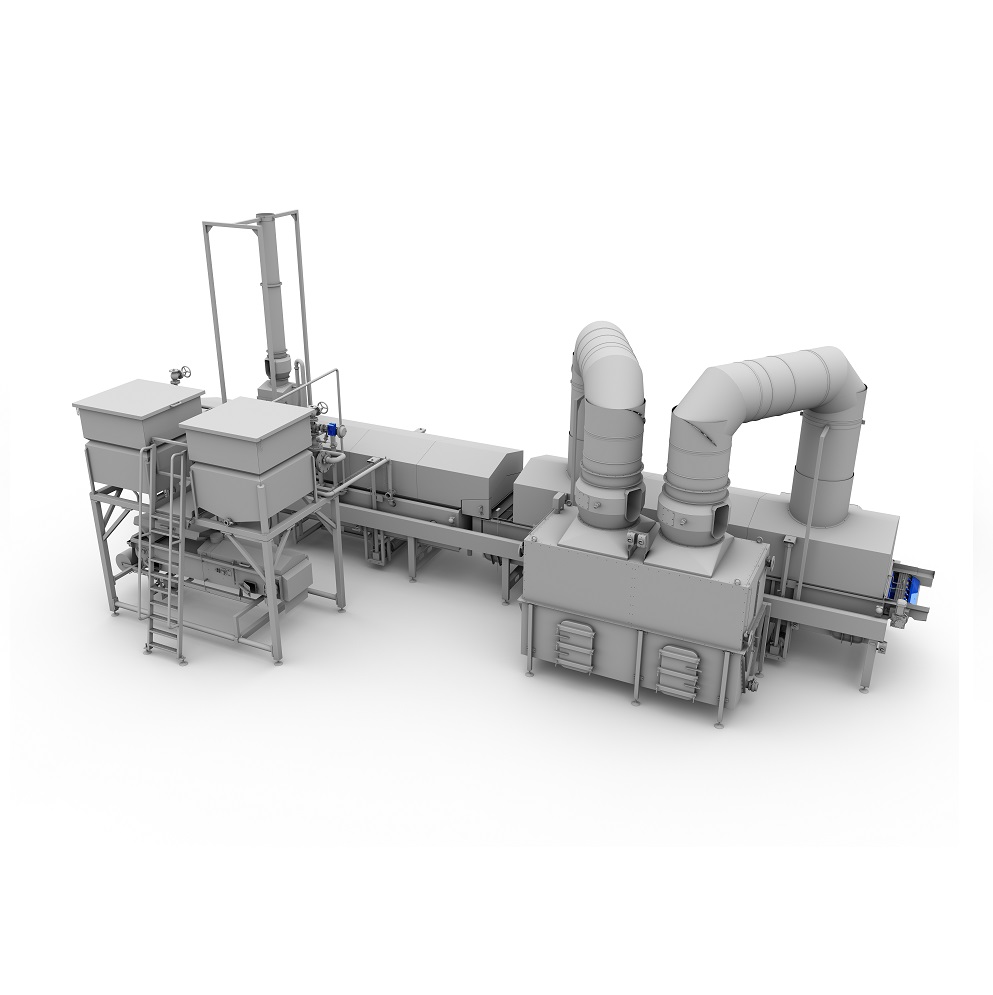

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

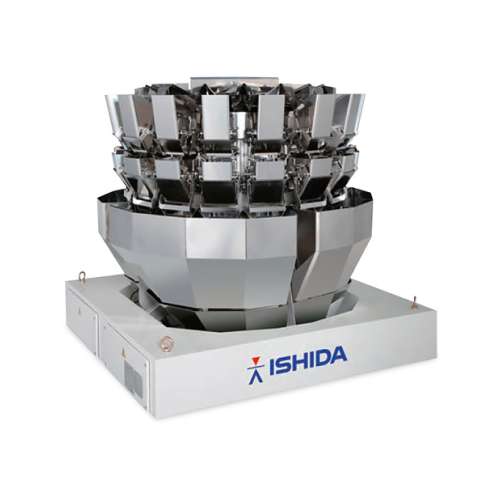

Blending multihead weigher for accurate component mixing

Achieve precise blending in high-speed operations with individua...

Continuous cocoa bean roaster

Achieve precise flavor profiles in cocoa and nut processing with a continuous roasting solutio...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Packaging conveyor for efficient bag handling

Simplify your packaging line with a conveyor designed to efficiently transfe...

Single lane collator for packaging room

Streamline your packaging operations by efficiently collating, counting, and aligni...

Smart pack conveyor systems for packaging room

Efficiently manage the flow of snack and nut products from packaging to dis...

High capacity continuous puffer for popcorn

Optimize your snack production with advanced airflow and speed controls design...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Rotary oven for japanese peanuts

Achieve uniform coating and optimal roasting for Japanese-style peanuts with precise temper...

Seasoning system for snack products

Optimize your snack production with precise oil, salt, and seasoning distribution, ensu...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Continuous dry popcorn popper

For snack producers aiming to consistently deliver high-capacity popcorn output, this advanced...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

Granulator for nut processing

Efficiently transform various nut varieties into uniform, sharp-edged granules while minimizin...

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

Retractable spiral chute for bulk material handling

Enhance the integrity of your products by gently transferring bulk ma...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

Integrated nut butter production line

Enhance your nut processing capabilities with a fully integrated production line that...

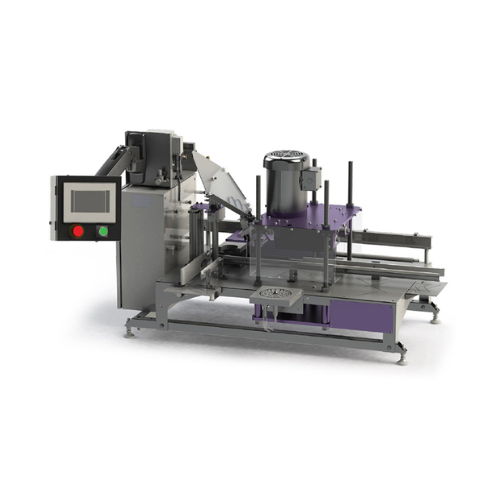

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

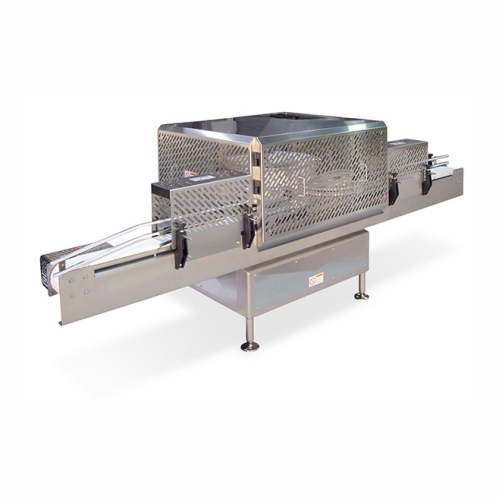

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

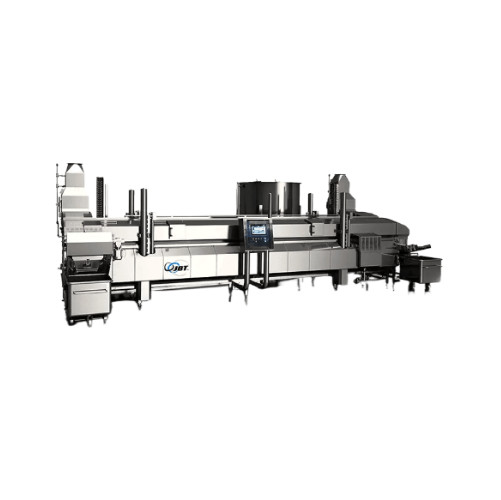

Direct heated immersion fryer for convenience food processing

Achieve superior temperature control and minimize oil cons...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

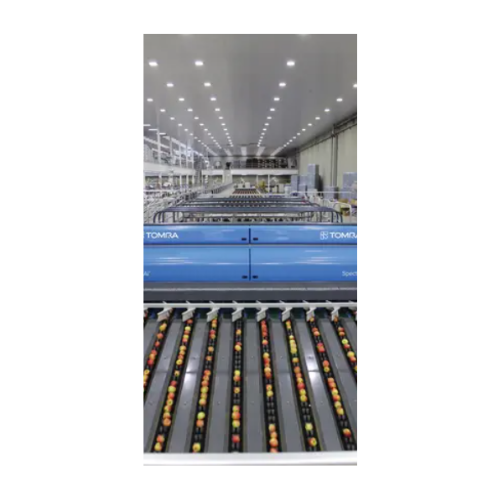

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Wet almond peeling machine for nut processing

Enhance your nut processing efficiency by achieving up to 98% peeling rate w...

Potato and sweet potato cleaning and peeling system

Streamline your root vegetable processing with a robust system design...

Industrial almond slicer for nut processing

Achieve precise nut slices with adjustable thickness, perfect for enhancing pa...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Almond sheller

Streamline your nut processing operations with a high-efficiency shelling machine designed for precision cracki...

Screw oil press for edible oil extraction

Optimize your oil extraction process with this screw oil press, designed to effi...

Garlic peeling equipment for industrial applications

Achieve optimal peeling efficiency with this garlic and nut peeling ...

Continuous fryer for high-capacity industrial frying

Achieve consistent high-capacity frying with this continuous mesh be...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

Automatic peanut peeling system

Achieve seamless peanut processing by eliminating red skins efficiently, enhancing the quali...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Electrostatic drum flavoring system for food processing

Enhance your snack production efficiency with a system designed t...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Vacuum and Gas Injection System for FIBCs

Products packed in large bulk bags, such as FIBCs, require vacuum pressure and a...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

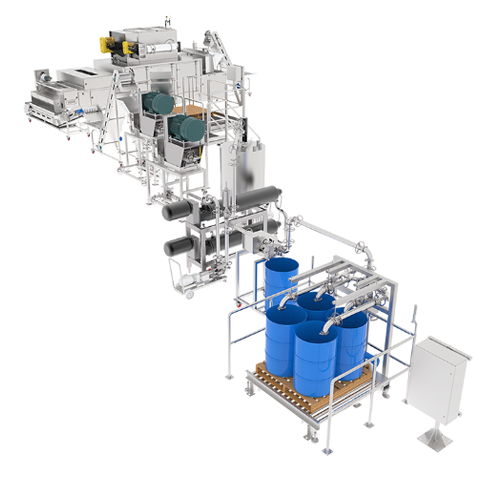

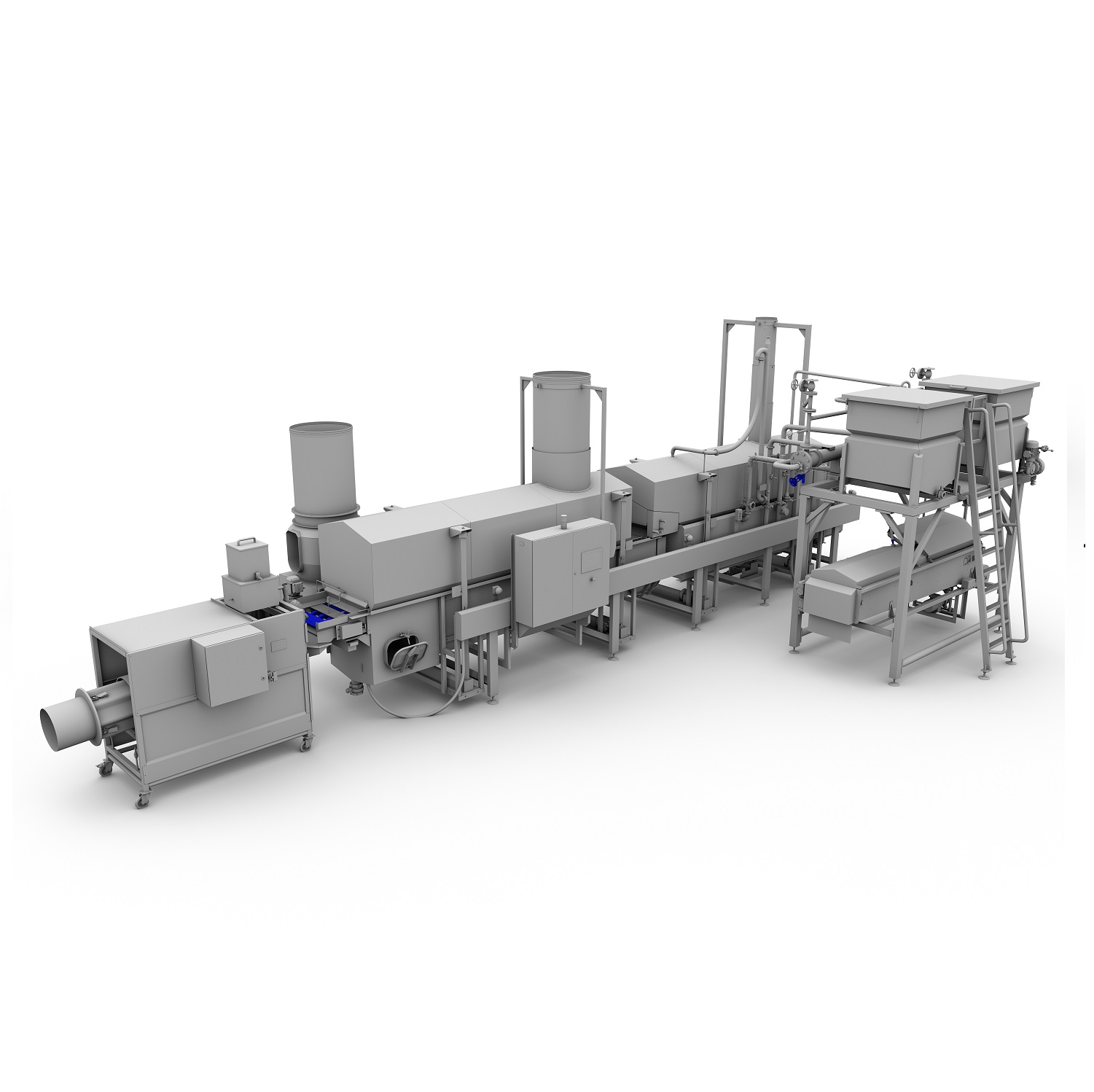

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

Peanut frying line

Fried peanuts are a very popular snack around the world. If you are looking to start a nut processing plan...

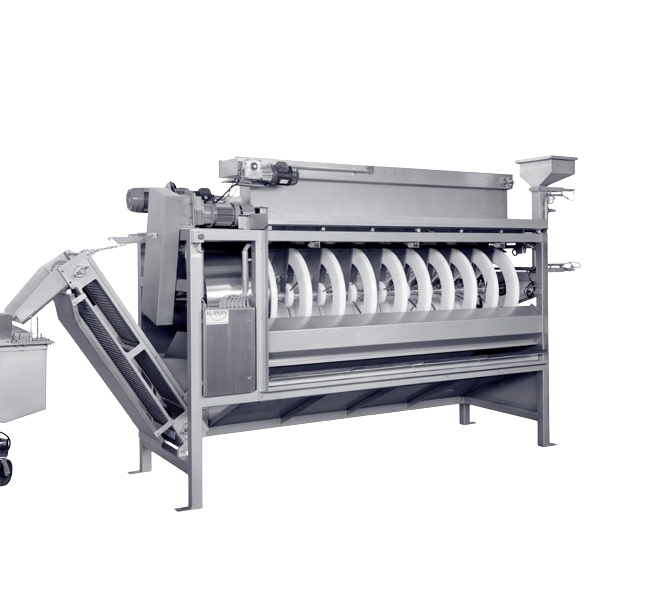

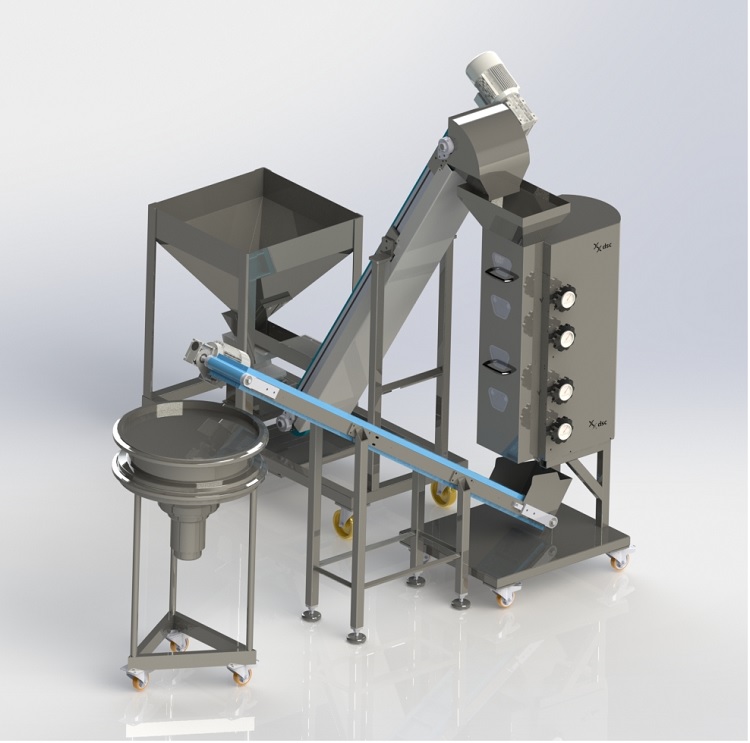

Continuous, automatic coating machine for peanuts

If you are in the peanut processing industry, bringing out delicious va...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

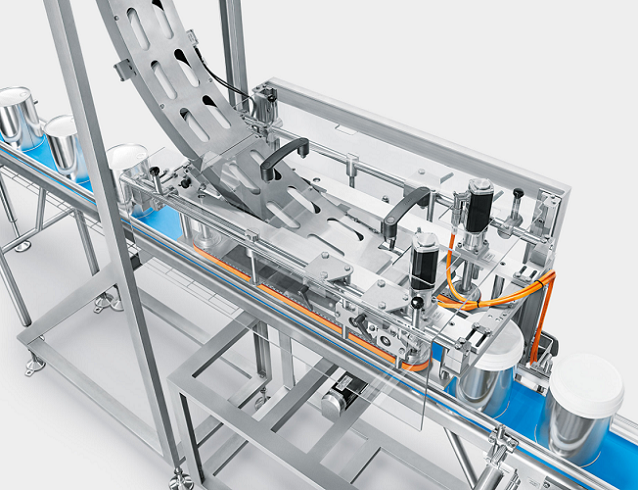

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

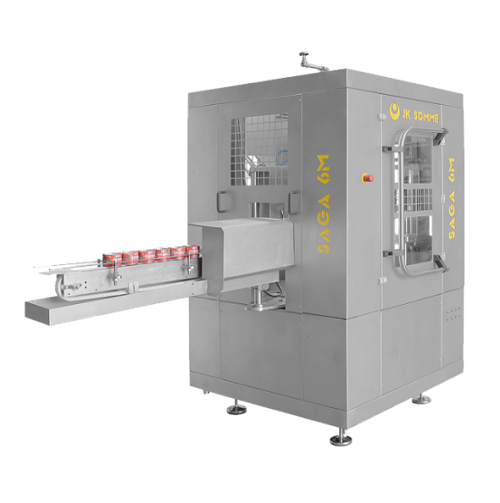

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

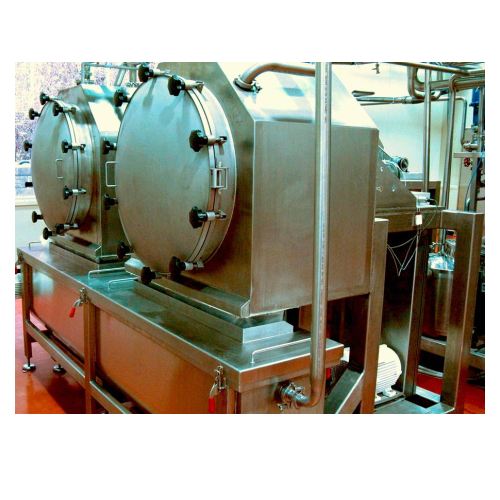

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.