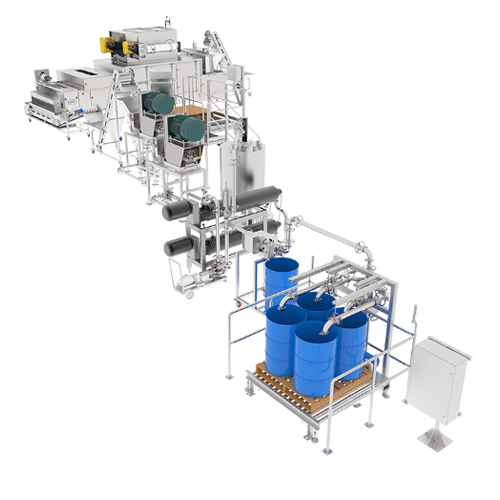

Integrated nut butter production line

Enhance your nut processing capabilities with a fully integrated production line that streamlines nut butter creation, ensuring seamless coordination from milling to packaging, with precise control and efficiency.

Processes Nut Butters and Specialty Nut Products

The Nut Butter Processing Line from AC Horn Manufacturing offers a robust and integrated solution for food processors and nut butter manufacturers. This line specializes in efficient processing of various nut butters and specialty products through coordinated equipment including roasters, granulators, and nut mills. Utilizing a fully automated system integrated via a bespoke control panel, the line ensures seamless operation across continuous shifts.

AC Horn’s unique capability lies in tailoring system integration to fit your specific production needs, whether your focus is on peanut, almond, or cashew butter or on flavored roasted nuts and coated varieties. With the flexibility to handle diverse operations, the line supports both solid and liquid product types, optimizing the entire manufacturing process.

Designed for industrial food production facilities, the Nut Butter Processing Line maintains high throughput while reducing operational costs, owing to energy-efficient motor control systems. All components are constructed with durable materials to ensure longevity and compliance with food industry standards.

The integration of advanced project management and engineering support ensures a fully customized setup, with complete project oversight from design through commissioning. This guarantees not only a smooth installation but also a refined production line tailored to your facility’s unique requirements.

Benefits

- Enhances production efficiency with seamless system integration and automated controls.

- Lowers operational costs through energy-efficient processing with optimized motor control.

- Offers versatile product handling for a wide range of nut butters and coated nut products.

- Ensures food safety and compliance with industry standards through robust material construction.

- Provides comprehensive project management to streamline installation and commissioning.

- Applications

- Japanese peanuts, Coated nuts, Snacks, Roasted nuts, Pellets, Chips, Popcorn, Corn tortillas, Blanched peanuts, Nut butter

- End products

- Flavored roasted nuts, Hazelnut butter, Mixed nut snacks, Cheese popcorn, Blue corn tortillas, Cashew butter, Peanut butter, Corn chips, Almond butter, Salted blanched peanuts, Honey-coated nuts, Caramel popcorn, Chocolate-coated nuts, Extruded snack pellets, Wasabi japanese peanuts

- Steps before

- Roasting, Grinding

- Steps after

- Packaging, Commissioning, System Integration

- Input ingredients

- nuts, raw peanuts, ingredients for nut butter

- Output ingredients

- nut butter, processed nut butter, packaged nut butter

- Market info

- AC Horn Manufacturing is renowned for its expertise in manufacturing industrial equipment for food processing, particularly in nut processing, popping equipment, and material handling systems, known for high-quality engineering and reliable performance in demanding industrial applications.

- Automation

- Custom program, PLC-controlled

- System Integration

- Fully automated, seamless operation

- Project Completion

- On-time delivery

- Design/Engineering

- Complete drawing sets provided

- Control System Integration

- Central control panel

- Working mechanism

- Integrated system

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Minimal

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- System integration

- Fully Automated

- Cleanability

- Easy to clean, suitable for hygienic processing

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Variable, suitable for nut butter texture

- Footprint

- Variable, depends on setup

- Control panel type

- Integrated main panel

- Discharge method

- Automatic/Centralized

- Control panel type

- Main control panel

- Integration possibilities

- System integration for fully automated line

- System integration

- Custom program by Horn programmer

- Project management

- Complete management by supplier

- Design/engineering

- Custom drawing sets