Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-intensive tasks of palletizing and depalletizing, ensuring precision and speed while reducing manual handling and the risk of injury.

Automates Palletizing and Depalletizing Operations

Viking Masek’s robotic palletizing and depalletizing systems, powered in collaboration with IAS, Inc., specialize in optimizing the handling of pallets in diverse industrial settings, such as food, beverage, and medical manufacturing. Leveraging a high-speed automation framework, they seamlessly integrate with existing production lines, accommodating solid, powder, granule, and liquid products. These systems offer swift handling of large volumes, catering to products ranging from granola bars to insulin pens. Equipped with intelligent robotic controls, they ensure precise stacking and unloading, reducing manual labor and enhancing throughput. Built with robust materials, they endure the demands of various operational conditions, and their PLC-based design allows for easy integration with remote monitoring tools. Viking Masek’s solutions are engineered for versatility, meeting specific customer needs with customized layouts and configurations.

Benefits

- Enhances operational efficiency by automating labor-intensive pallet handling tasks.

- Increases production line integration with versatile material handling capabilities.

- Reduces labor costs with precise, high-speed robotic controls.

- Minimizes downtime with robust materials designed for continuous operation.

- Supports industry-wide compatibility with customizable configurations.

- Applications

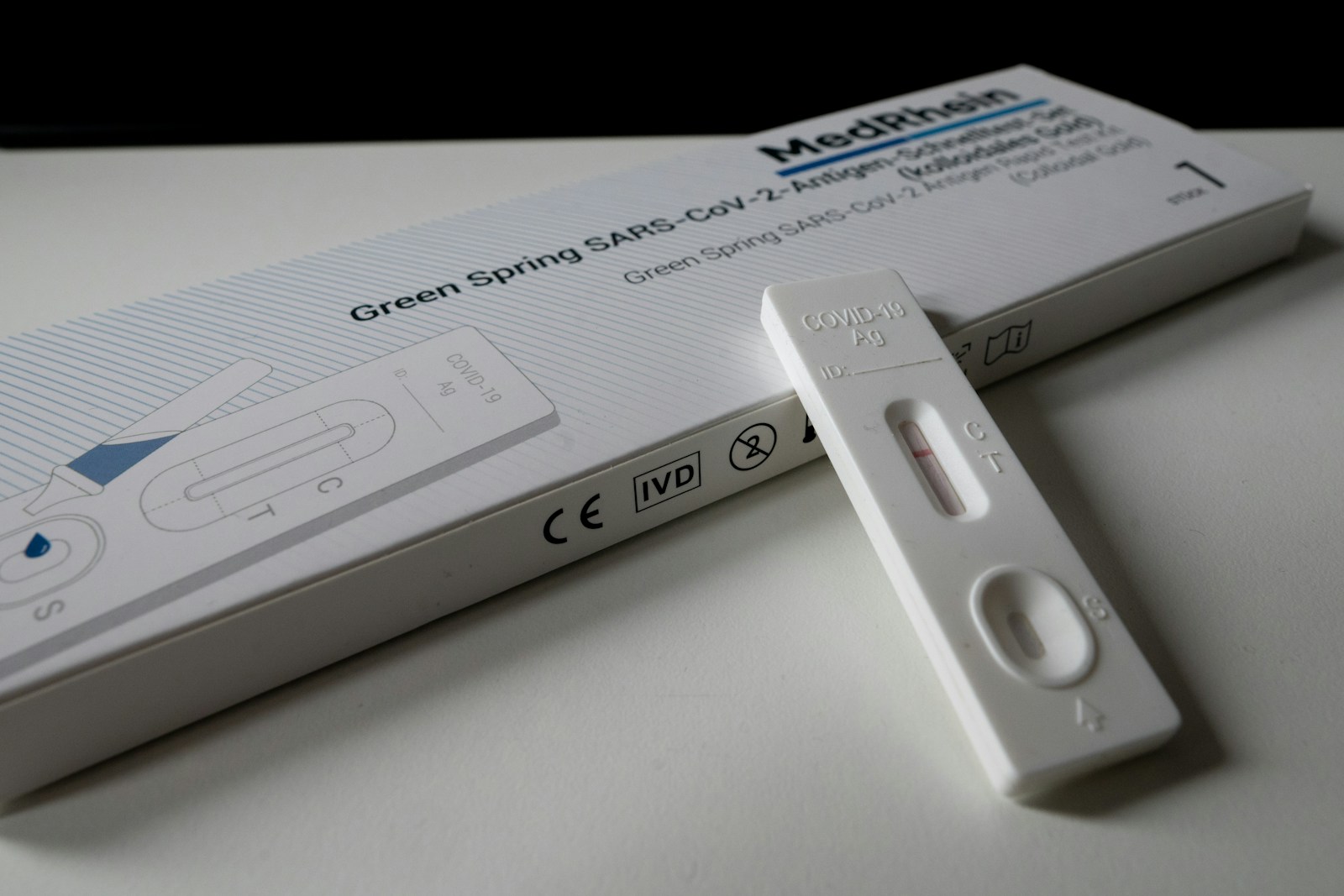

- Contract packaging, Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Powders, Candy, Pasta, Pet food, Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Vegetables, Poultry, Medical

- End products

- Dog biscuits, Spaghetti, Sauces, Bottled water, Fruit snacks, Lentils, Vitamin tablets, Protein shakes, Sterile gloves, Protein powder, White rice, Gluten-free bread, Soft drinks, Cookies, Apple slices, Salmon fillets, Chicken breasts, Hemp flower, Quinoa, Powdered milk, Muesli bars, Olive oil, Multigrain bread, Cornflakes, Nutritional supplements, Organic yogurt, Cat food, Granola, Sausages, Cashews, Almonds, Peanuts, Cbd oil, Fish oil capsules, Blue cheese, Insulin pens, Carrot sticks, Chocolate bars, Covid-19 test kits

- Steps before

- Material Sorting, Bulk Product Delivery

- Steps after

- Shipment Preparation, Pallet Wrapping

- Input ingredients

- bulk product, incoming pallets, cases, raw materials

- Output ingredients

- stacked pallets, finished product cases, organized cases, packaged goods

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Automation

- Robotic

- Automation

- Palletizing/Depalletizing

- Speed

- High-speed

- Capacity

- High capacity

- Handling type

- Bulk product

- Operation type

- Precision stacking

- Collaboration

- Partnered with IAS, Inc.

- Automation level

- Robotic / PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Minimal / Quick setup

- CIP/SIP

- N/A

- Cleaning method

- N/A

- Energy efficiency

- High

- Precision level

- High

- Speed

- High throughput

- Product type

- Cases, bags, boxes

- Machine footprint

- Compact

- Shape

- Rectangular

- Discharge method

- Robotic Arm

- Control panel type

- Touchscreen

- Customization

- Available for specific needs

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Robotics integration compatible

- Footprint

- Compact design

- System flexibility

- Customizable stacking patterns

- Scalability

- Expandable modules