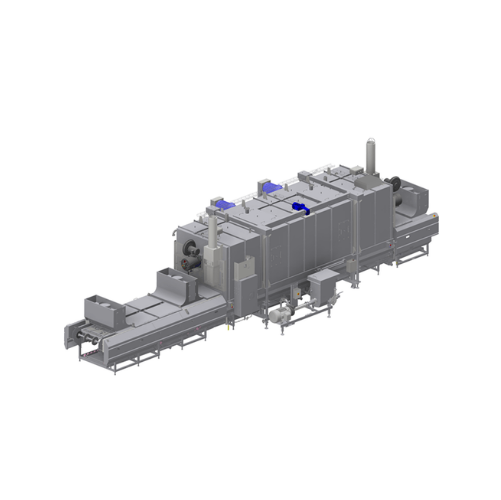

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their natural texture by using high temperature short dwell pasteurization, achieving reliable Salmonella reduction while maintaining product integrity.

Surface Pasteurizes Nuts and Dried Fruits

The Stein JSP Jet Stream® Surface Pasteurizer from JBT offers nut processing companies and food safety specialists an effective solution for ensuring product safety. This conveyorized system specializes in surface pasteurization, achieving a consistent five log reduction of Salmonella Enteritidis PT 30 without compromising the raw appearance of nuts and dried fruits. Utilizing high-temperature, short dwell time processes, it features a two-zone chamber combining steam and high-velocity impingement to deliver powerful heat transfer. With ProLINK™ user-friendly controls and a vibratory conveyor feed system, it integrates seamlessly into continuous production lines, while the patented Humitrol® system automatically regulates moisture. Designed to meet FDA requirements, the Stein JSP ensures thorough sanitation with its automatic Clean-in-Place system and offers models with varying belt sizes and pasteurization chamber lengths to suit different processing needs.

Benefits

- Ensures food safety with consistent five log Salmonella reduction, enhancing product reliability.

- Preserves product aesthetics by maintaining raw-like appearance, crucial for consumer acceptance.

- Streamlines operations with continuous, automated processing, minimizing labor intervention.

- Meets regulatory standards efficiently, ensuring compliance with FDA requirements.

- Facilitates quick cleaning and reduces downtime with automatic Clean-in-Place capabilities.

- Applications

- Food safety, Salmonella reduction, Fruits, Low moisture applications, Nuts

- End products

- Peanuts, Dried fruits, Pecans, Figs, Macadamia nuts, Dried apricots, Raisins, Walnuts, Pistachios, Nut-based snacks, Cashews, Dates, Almonds, Trail mixes

- Steps before

- Cleaning, Sorting, Drying, Weighing

- Steps after

- Cooling, Packaging, Labeling, Storage

- Input ingredients

- nuts, almond, low moisture products

- Output ingredients

- pathogen-free surface, Salmonella Enteritidis PT 30 reduced, pasteurized nuts, raw-like appearance preserved

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Automation

- Fully automatic

- Process type

- Continuous

- Conveyor type

- Vibratory conveyor feed system

- Heating system

- Indirect heating system

- Dwell time

- Short

- Reduction efficiency

- Five log reduction of Salmonella Enteritidis PT 30

- Chamber type

- Two Zone pasteurization chamber

- Cooling system

- Automatic Clean-in-Place (CIP) system

- Belt type

- Chain edge drive mesh belt

- Belt width

- 40 inch / 24 inch usable belt

- Chamber length

- 22 ft. / 16 ft. long pasteurizing chamber

- Infeed section length

- 15.5 ft. long

- Discharge section length

- 5.5 ft.

- Airflow control

- Automatic adjustment of top and bottom vertical airflow

- Hood design

- Clam shell hood with automatic hood lift

- Working Mechanism

- Conveyorized system

- Integrated Steps

- Steam and Impingement Zones

- CIP/SIP

- Automatic Clean-in-Place System

- Automation Level

- Fully Automatic Continuous Process

- Batch vs. Continuous Operation

- Inline Continuous

- Abrasion resistance

- High

- Biological compatibility

- Yes (pathogen-free surface)

- Cleanability

- Automatic Clean-in-Place (CIP) system

- Corrosive resistance (e.g. acids)

- High (indirect heating system)

- Application type

- Low moisture

- Product type

- Nuts, fruits

- FDA materials

- 21 CFR Part 11

- Machine footprint

- 40 inch usable belt and 22 ft. long pasteurizing chamber (JSP-1), 24 inch usable belt and 16 ft. long pasteurizing chamber (JSP-C)

- Feed method

- Vibratory conveyor feed system with built-in hopper

- Discharge method

- 5.5 ft. discharge section

- Zone configuration

- Two Zone pasteurization chamber (steam zone, impingement zone)

- Drive type

- Chain edge drive mesh belt with electric drives

- Hood design

- Clam shell hood design with automatic hood lift

- Airflow system

- Automatic adjustment of upper plenums and top and bottom vertical airflow

- Control panel type

- ProLINK™ user friendly controls

- Conveyor belt size

- 40 inch usable belt for JSP-1, 24 inch usable belt for JSP-C

- Pasteurizing chamber length

- 22 ft. for JSP-1, 16 ft. for JSP-C

- Transition chamber length

- Two or four ft. options

- Feeding system

- Vibratory feeding system with built-in hopper

- Hood design

- Clam shell hood design with automatic hood lift