Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts and seeds with a rotary can filler, ensuring continuous packaging without jams or spills, tailored to a wide range of container sizes.

Fills and Packages Dry Free-Flowing Products

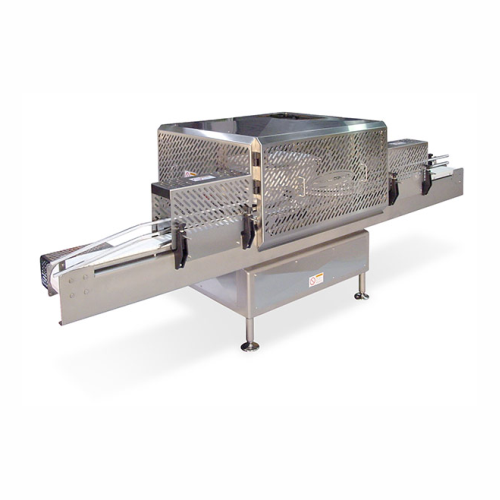

The Rotary Can Filler from Heat and Control is engineered for seamless high-speed packaging operations in the food processing and nut packaging industries. This continuous motion system uses precision indexing to accurately fill dry free-flowing products, such as roasted almonds and mixed nuts, into various containers. Capable of processing up to 90 containers per minute, the equipment integrates smoothly with existing conveyor systems, ensuring minimal downtime and high production efficiency. Designed for durability, it offers IP65 washdown protection, making it suitable for rigorous cleaning protocols. Optional stainless steel construction enhances corrosion resistance, catering to specific material requirements. Its straightforward design allows easy adjustments for different container sizes, and the system is equipped with a user-friendly PLC interface for full process control and remote monitoring. A valuable addition to any packaging line, the Rotary Can Filler promises reliable, precise performance with customizable support from Heat and Control’s engineering team.

Benefits

- Maximizes packaging speed with the ability to fill up to 90 containers per minute.

- Enhances production flexibility by easily adjusting to different container sizes and types.

- Minimizes operational downtime with its jam-proof design and reliable container handling.

- Supports stringent hygiene standards with IP65 washdown capability for thorough cleaning.

- Improves operational efficiency via PLC-controlled system for precise and automated filling processes.

- Applications

- Nuts, Dry free-flowing products

- End products

- Roasted almonds, Trail mix, Cashew nuts, Mixed nuts, Salted peanuts, Sunflower seeds

- Steps before

- Blending, Inspection, Weighing, Conveying, Roasting, Seasoning

- Steps after

- Packaging, Inspection, Weighing, Conveying

- Input ingredients

- dry free-flowing products, containers, jars, canisters

- Output ingredients

- precise net weight packages, filled cans, filled jars, filled canisters

- Market info

- Heat and Control is known for manufacturing industrial food processing and packaging equipment. They have a strong reputation for providing innovative, high-quality solutions tailored to meet specific customer requirements in the food industry.

- Filling speed

- Up to 90 containers per minute

- Container size compatibility

- Adjustable for a wide range of container heights and diameters

- Filling method

- Volumetric

- Filling accuracy

- Precise net weight packaging

- Product compatibility

- Dry free-flowing products

- IP rating

- IP65 washdown

- Automation level

- Continuous motion

- Working mechanism

- Continuous rotary motion

- Integrated steps

- Filling and indexing

- Automation level

- PLC-controlled

- Changeover time

- Fast and easy-to-adjust

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- Varies (adjustable for heights and diameters)

- Container type

- Cans, jars, canisters

- Product type

- Dry free-flowing products

- Discharge method

- Starwheel system

- Compact footprint

- Designed for easy installation

- Feed method

- Single-lane conveyor

- Container handling

- Adjustable for height and diameter

- Container size compatibility

- Adjustable height and diameter