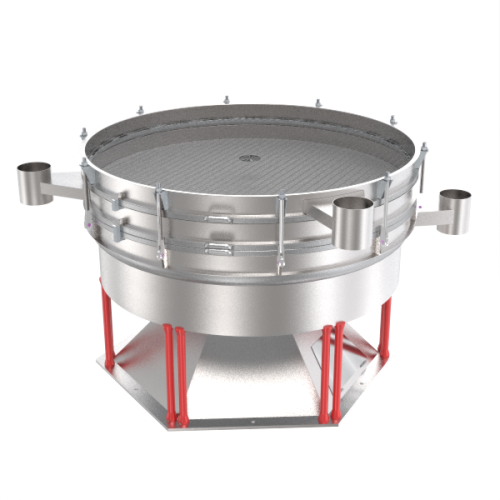

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your production line efficiency even with high-fat content materials using this advanced circular sifter.

Grades and Sieves Nuts and Flours

Maseto’s Circular Sifter is a versatile screening machine designed for continuous, high-speed grading and sieving of nuts and flours. It features a customizable multi-grader system, offering 1 to 4 graders for selecting up to 5 different product sizes via adjustable mesh variations. The equipment is ideal for applications such as almond flour, macadamia nut oil, and cashew nut snacks. It can process up to 20,000 kg/h, making it suitable for large-scale food, nut processing, and agricultural operations. The Circular Sifter integrates seamlessly into existing production lines with its user-friendly PLC control, minimizing energy use and enabling efficient process management. Constructed with durable materials, it includes self-cleaning systems to reduce maintenance downtime and prevent mesh clogging, ensuring optimal operation.

Benefits

- Ensures precise product grading, enhancing end-product quality.

- Increases processing efficiency with customizable mesh sieves.

- Minimizes downtime with integrated self-cleaning systems.

- Enhances energy efficiency in high-capacity operations.

- Seamlessly integrates into existing production lines, simplifying setup.

- Applications

- Nuts, Flours, Fatty products

- End products

- Cashew nut snack, Sesame seed oil, Tiger nut milk, Hazelnut meal, Pistachio paste, Peanut butter, Apricot kernel powder, Macadamia nut oil, Almond flour, Brazil nut meal

- Steps before

- Cleaning, Washing, Drying

- Steps after

- Selection, Sieving

- Input ingredients

- Almendra, Anacardo, Avellana, Cacahuete, Chufa, Coquito de Brasil, Pepita de Albaricoque, Macadamia, Nuez, Pistacho, Sésamo

- Output ingredients

- graded product by size

- Market info

- Maseto is known for supplying industrial engineered-to-order (ETO) equipment, specializing in custom machinery solutions for various sectors. Their expertise lies in advanced engineering, innovation, and high-quality manufacturing, earning them a strong reputation for reliability and precision.

- Capacity

- 500–20000 kg/h

- Screens/Graders

- 1, 2, 3 or 4 graders

- Product Selections

- 2 to 5 different selections

- Mesh Sizes

- Variable

- Self-cleaning system

- Yes

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Self-cleaning system

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleanability

- Self-cleaning system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Type

- Nuts, Seeds, Flour

- Self-cleaning Requirement

- Yes

- Screen Grading Options

- 1 to 4 graders

- Product Selection Variability

- 2 to 5 selections

- Machine footprint

- Compact

- Sieve configuration

- 1 to 4 graders

- Mesh variation

- 2 to 5 selections

- Self-cleaning system

- Included in smaller sieves

- Number of graders

- 1, 2, 3, or 4 graders

- Product selections

- From 2 to 5 different product selections

- Mesh sizes

- Variable mesh sizes

- Self-cleaning system

- Available for smaller sieves