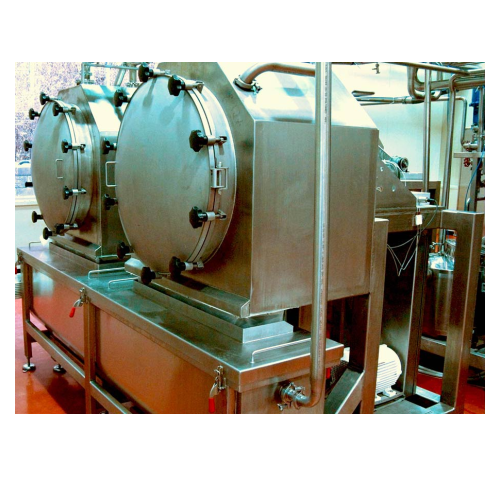

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely process almonds into quality milk, ensuring optimal texture, flavor, and nutrient fortification while minimizing waste.

Processes and Packages Almond Milk Variants

The Almond Milk Processing and Packaging Machine from ProSoya efficiently transforms raw almonds into diverse, high-quality plant-based milk products. Utilizing an integrated process of blanching, grinding, mixing, and homogenization, it ensures minimal waste and optimal product consistency. Ideal for food and beverage industries, this equipment produces unsweetened almond milk and fortified variants, catering to growing demand for dairy alternatives. With a continuous operation, it accommodates various packaging needs for both chilled and ambient distribution, offering aseptic and retorted options. The machine supports CIP (Clean-In-Place) for seamless cleaning, minimizing downtime. Available with PLC-controlled systems for automation, it can be customized based on throughput requirements, ensuring seamless integration into existing production lines.

Benefits

- Minimizes waste by utilizing all raw almond materials efficiently.

- Reduces packaging-related logistical costs with versatile storage options, including aseptic and retorted packaging.

- Enhances product quality and consumer appeal with customizable formulations and fortifications.

- Seamlessly integrates into existing operations with PLC-controlled automation, reducing labor costs.

- Ensures quick adaptation to process changes with customizable throughput and operation controls.

- Applications

- Dairy alternatives, Plant-based milk, Nut milks, Vegan beverages

- End products

- Almond paste milk, Blanched almond milk, Almond milk in aseptic packaging, Unsweetened almond milk, Whole almond milk, Almond milk with vitamins and calcium, Almond milk in retorted packaging

- Steps before

- Purification, Blanching, Grinding

- Steps after

- Fortification, Packaging, Storage

- Input ingredients

- whole almonds, blanched almonds, almond paste

- Output ingredients

- almond milk, unsweetened almond milk, vitamins and calcium fortified almond milk

- Market info

- Prosoya is known for its expertise in manufacturing soy milk production equipment, providing innovative solutions for efficiently processing soybeans into soy milk and related products, highly regarded for its advanced technology and customizable engineering solutions.

- Raw Material Type

- Whole almonds, blanched almonds, almond paste

- Packaging Options

- Chilled

- Ambient

- aseptic pouch/carton/bottle, retorted pouch/bottle/can

- Product Features

- Unsweetened, fortified with vitamins and calcium

- Production Capability

- Turnkey solution

- Cost Efficiency

- Minimum cost per unit volume

- Flavor and Texture

- Good product body, mouthfeel, flavor

- Shelf Stability

- Stable

- Working mechanism

- Batch / Continuous

- Integrated steps

- Grinding / Blanching / Filtration / Packaging

- CIP/SIP

- Clean-in-Place (CIP) / Steam-in-Place (SIP)

- Batch vs. continuous operation

- Batch

- Automation level

- Automated / Manual

- Container size and shape

- Bottle / Carton / Pouch

- By-product minimization

- Zero waste

- Machine footprint

- Variable based on configuration

- Tank shape and size

- Varies for different input materials

- Feed/discharge method

- Customized based on packaging type

- Control panel type

- Programmable Logic Controller (PLC)

- Packaging options

- Bottle, Carton, Pouch, Aseptic Packaging, Retorted Packaging

- Raw material compatibility

- Whole Almonds, Blanched Almonds, Almond Paste

- Customization for product type

- Nut milks such as Peanut, Hazelnut, Walnut, Cashew, Macadamia, Sesame, Flaxseed, Hemp

- Integration possibilities

- Turnkey Solutions

- Waste reduction capability

- Full usage of raw material with no by-product