Let's make healthy snacks

Find innovative healthy snacks equipment and connect directly with world-leading technology suppliers

If Popeye needed spinach for his power, you need healthy snacks to boost your energy! From dried fruit chips to nuts and protein bars, healthy snacks have become more popular since the 2000s, and the global healthy snack market will reach USD 98 billion by 2025. In the wide range of healthy snacks, raw fruits and vegetables appear as the main ingredient, and these snacks focus on the high protein content and reduced fat or carbohydrate percentages. Also, “less processed” and “less amount of added chemicals” are the primary trend in making healthy snacks as the clean eating movement began after the 2000s.

Top picks for producing healthy snacks

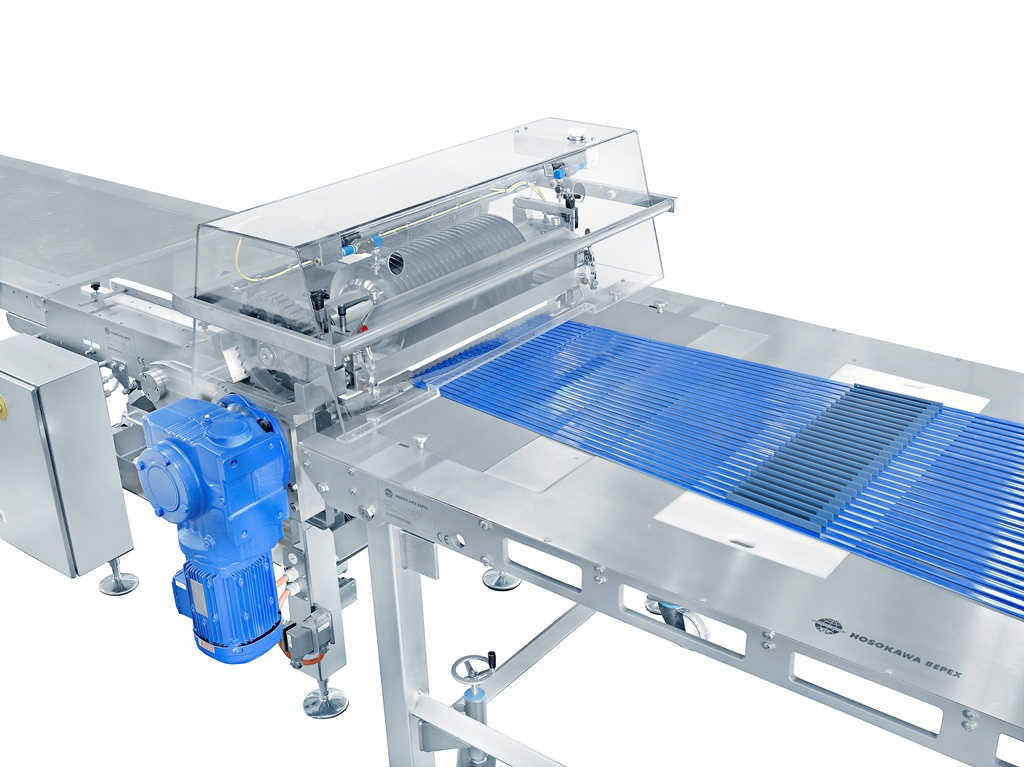

Flavouring system for healthy rice cakes and snacks

Being active on the market for healthy popped snacks asks for a flexi...

Flexible popped chips machine

Producers of healthy snacks like popped chips, are much more competitive when they are able to...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Vegetable and fruit dicer for commercial use

Efficiently transform a variety of produce into precise cubes, slices, or shr...

Stories about healthy snacks

From big bags to compact bags: use MAP in both

#Changemaker: Putting a label on sustainability

How to detect the smallest leaks in your sandwich packaging

#Changemaker: white chlorella as your next protein source!

#Changemaker: Try this spoonful of fermented buckwheat snack!

#Changemaker: Chips plus protein minus gluten

Select your healthy snacks process

Tell us about your production challenge

What exactly are healthy snacks?

“Healthy snacks” can be understood as a broad and ambiguous term. This term can be pretty unclear since the concept of healthy is subjective. In the healthy snack industry, healthy snacks are often recognized as snacks that are low in sugar, high in protein, no trans fats, and high in fiber. They are made of natural (possibly organic) ingredients grown without pesticides or antibiotics, with no added artificial colors, flavors, or preservatives. And all of these features are often labeled as one of the followings – whole grain, fiber-rich, high protein, no fats, gluten-free, organic, no added sugar, natural or no preservatives, probiotics, antioxidant-rich, or immunity-boosting.

The physical format of healthy snacks can be divided into three big categories – bars, chips, and mixed nuts. Bars are considered the most convenient form of healthy snacks as they are easy to take on the go. They are often made of whole grains, ancient grains, cereals, seeds, and nuts. Currently, cereal and granola bars and protein bars dominate this segment.

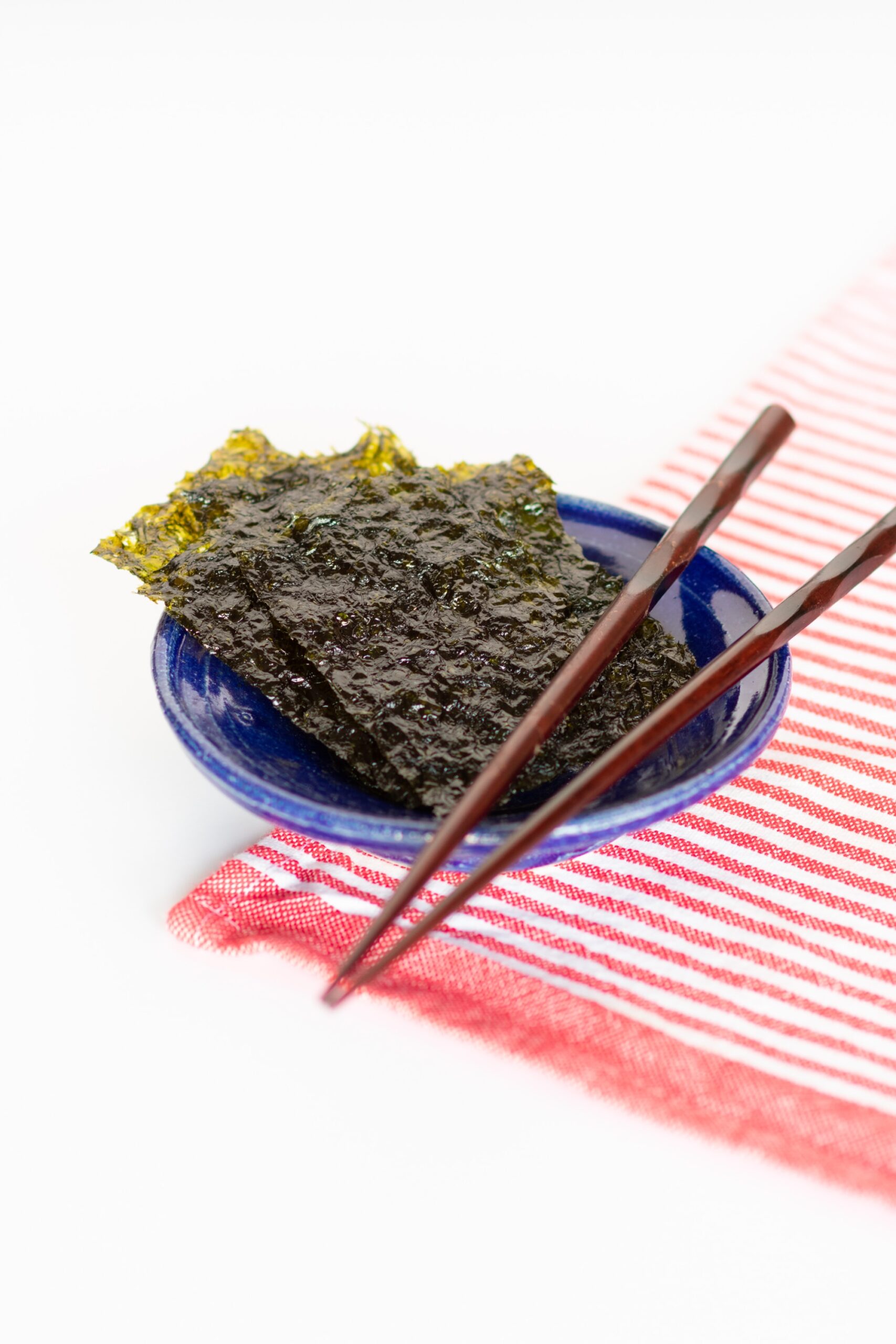

For the second category, there are chips. In the healthy snacks industry, chip manufacturers often attempt to produce a healthier version of conventional potato chips by replacing potatoes with multigrain, rice, corn, wheat, fruits, and vegetables. They focus on achieving low-fat, low sodium, and high nutrients in their products. The producers, hence, often use the baking method instead of frying or using all-natural non-GMO ingredients.

Lastly, there are nuts and seed mixes. They are beloved due to their portability, convenience, and variety in flavors; also, the natural attribute of being gluten-free and rich in omega contributes to their popularity. Ingredients like cashew, peanut, almonds, hazelnuts, flaxseeds, chia seeds, and hemp seeds are popular in nut and seed mix products.

New healthy snack production technologies – preserve the nutritional quality and taste of your ingredients!

Ultrasound and microwave-assisted vacuum frying technology is a new way of frying technology that can not only enhance the look of fried foods but also enhances the quality of food as it maintains the heat-sensitive and oxidation-sensitive nutrients. Also, since this technology is operated at a lower temperature than regular fryer machines, the producer utilizing this new vacuum frying technology can save more energy and earn higher yields.

Another new technology is pulsed electric field (PEF) pre-processing treatments. PEF uses pulses of electricity and pierces the cell membranes to emit further fluid out of fruits or vegetables. This non-thermal technology can maintain the nutrients of raw ingredients, and it helps the end product to contain a lower amount of sugar and acrylamide. Additionally, it saves water and energy consumption for operation by 90%.

Individual Quick Freezing (IQF) is a technology used to preserve raw ingredients by freezing them individually. Here, the freezing process takes only a few minutes, and the food ingredients are frozen separately. This freezing technology is famous for its ability to preserve the sensory and physio-chemical traits of raw ingredients. Often raw ingredients consisting of multiple small pieces such as berries, peas, and corn are treated with this technology.

What is trending in healthy snacks? – personalize your snacks for different demographics and pay attention to the environmental impact!

If you are a producer of healthy snacks, it is crucial to be aware of the new trends in the healthy snacks industry. Plant-based snack is a hot topic as there is a rise in vegetarian and vegan populations, specifically in the younger generation. Plant-based snacks incorporate ingredients like turmeric, ashwagandha, folic acid, and green tea, which can increase the product’s health value by providing additional vitamins and minerals.

Another topic is personalized snacks. Like the vegetarian or vegan trend, consumers nowadays seek snacks that can accommodate their lifestyle and dietary or health requirements. Consequently, customized nutrition became popular. Customers are less concerned about the sugar, fat, or protein content but more about how these snacks can meet the ideal lifestyle they aim to achieve. Mood-boosting, gut-friendly, and sleep-better snacks are examples of this topic.

Finally, there is a trend concerning the environment. When purchasing healthy snacks, customers would like to know if the product is trustworthy and sustainable. Hence, displaying a clear and honest explanation of the source of ingredients, manufacturing and packaging details (if they are recyclable or biodegradable), and farming and collection routes (concerning carbon footprint) became important factors for consumers. Naturally, upcycled snacks have been spotlighted as an environmentally friendly alternative that reduces waste generation.

Which healthy snacks technology do you need?

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Industrial dipping bath for prolonging shelf life of cut fruits and vegetables

Enhance the shelf life and hygiene of y...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

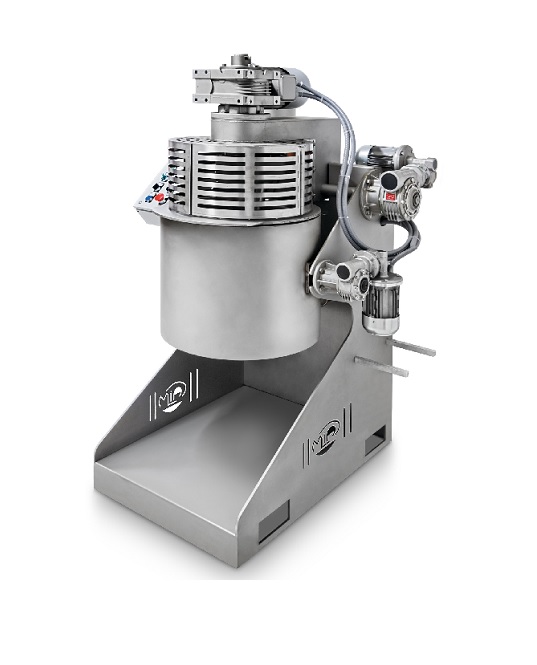

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Horizontal slow masticating juicer for maximum juice yield

Optimize your juice extraction process with a slow masticatin...

Vertical slow juicer for producing cold pressed juice

Achieve optimal juice quality and versatility with low-speed crushi...

Jumbo twin gear slow masticating juicer for high-yield juice extraction

Achieve optimal nutrient retention and extended...

Twin gear slow masticating juicer for vegetables and fruits

Achieve higher mineral content in your juices with this slow...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

Glass personal blender for nutrient preservation

Experience enhanced flavors and nutrient retention with advanced vacuum b...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

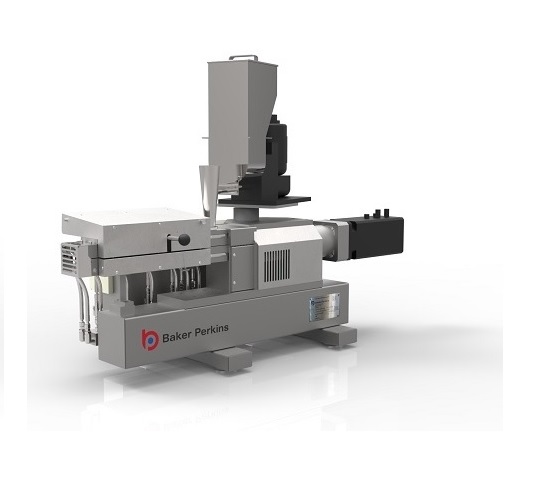

Continuous extruder for protein bars and super foods

Optimize your snack production with a continuous extrusion solution ...

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Industrial guillotine machine for extruded foods

Textured vegetable proteins made from soy, wheat, and oats are extruded i...

Benchtop extruder for cereals and snacks

Extruded products are very popular in the breakfast cereal and snack sectors. It i...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Cabinet dryer for cannabis

If you need careful drying for products like pharmaceutical-grade cannabis buds then traditional ...

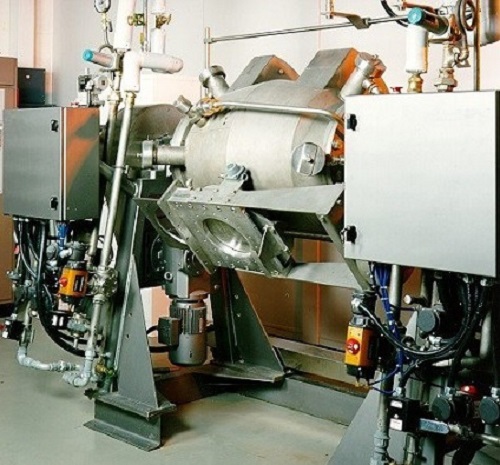

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

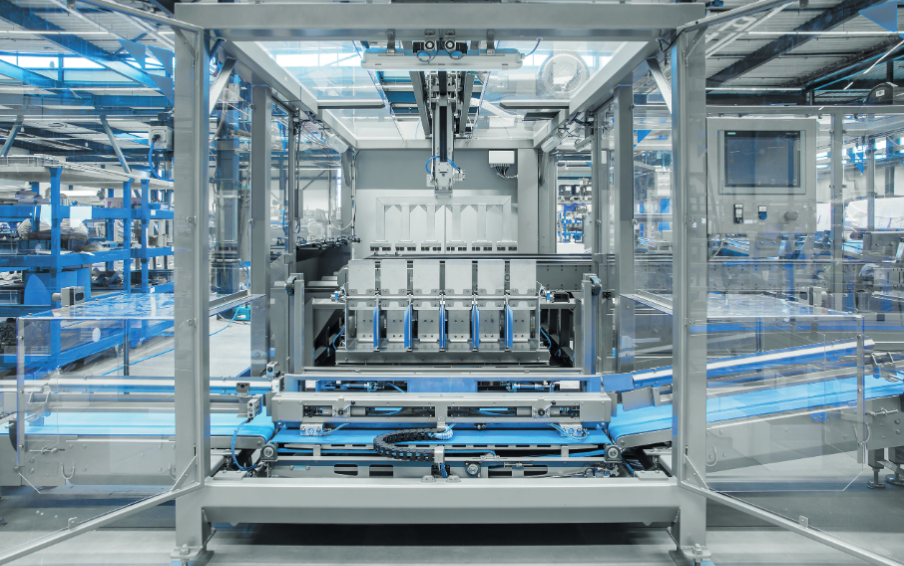

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Ultra-clean FFS machine for yoghurt in cups

Dairy products like yoghurt are very susceptible to spoilage. Yeasts and mould...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Industrial tunnel dryer for food sector

Dry foods are popular consumables and have their place on the market. In cases wher...

Industrial belt dryer for fruits and vegetables

The industrial belt dryer by Pigo is a simple yet super effective fruit an...

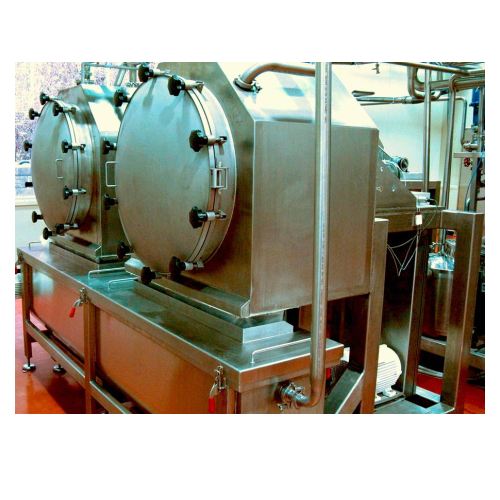

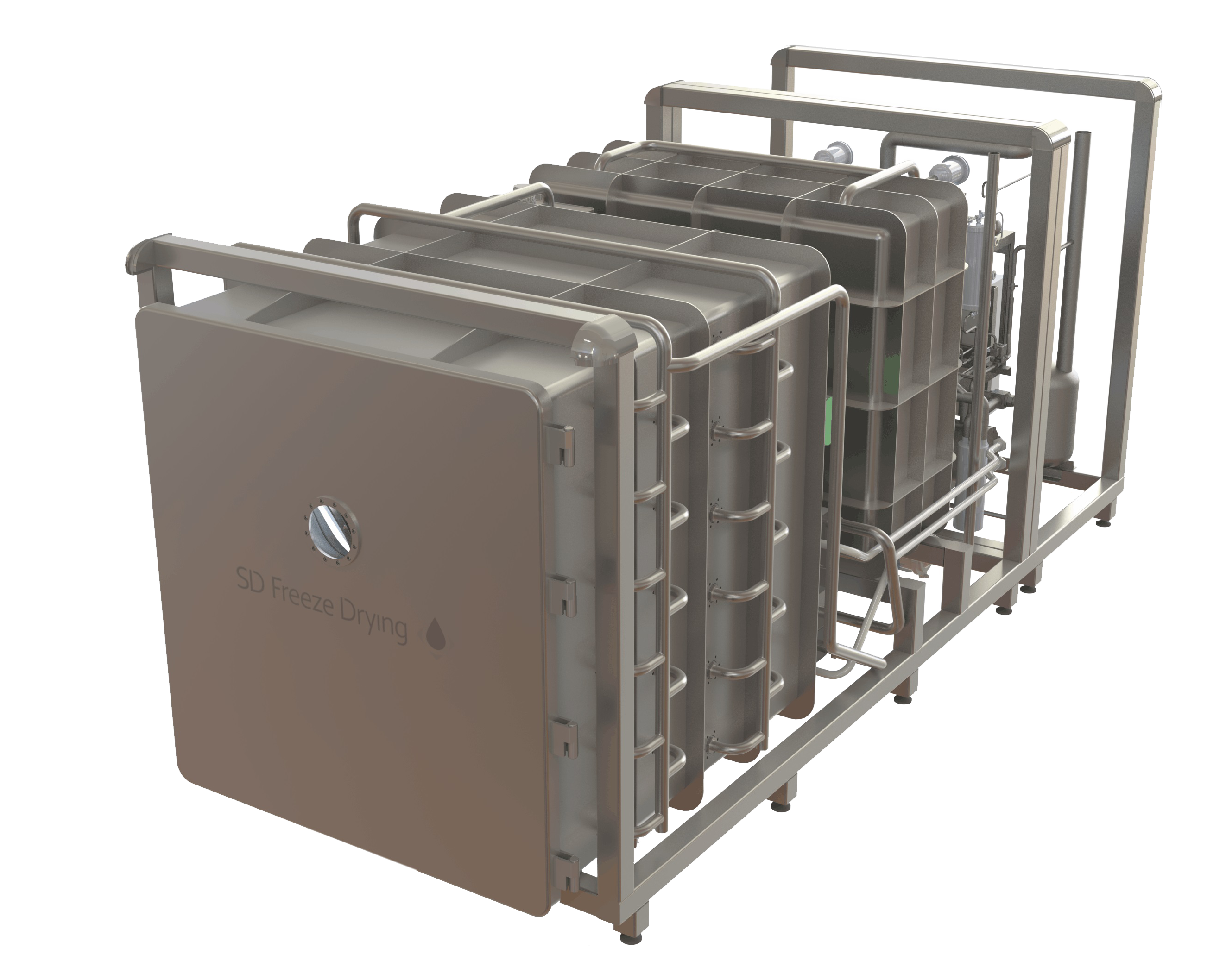

Industrial freeze-dryer for fruits

Freeze-drying is a complex and delicate process. If you are searching the market for a f...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

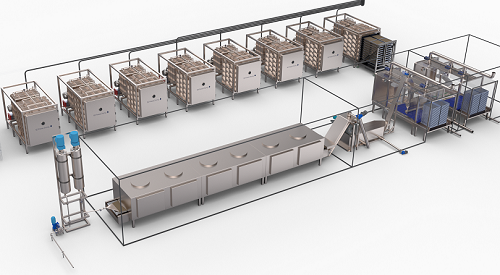

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

High-speed flow pack wrapping machine for chocolates

Foil flow pack wrapping of chocolate products is an attractive and p...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

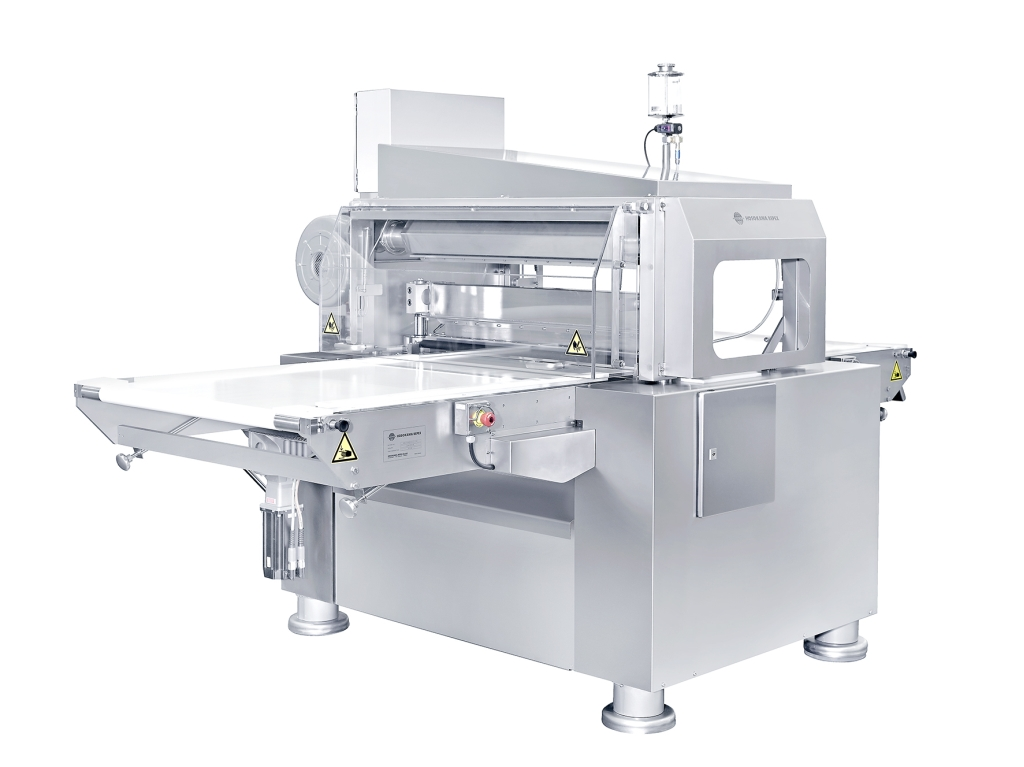

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

High capacity decorator

Enhance the appearance of your product by applying final finishing touches and designs. This is a ser...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Optical sorter for dried and frozen fruits

Dried fruits, frozen fruits, frozen vegetables and nuts present a challenge for...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Convection oven for granola

For high-quality granola products, a perfect bake is required for optimum color, taste, and mout...

Granola batch mixer

The production of granola-based recipes requires careful ingredients handling to ensure optimum quality. ...

Thin-film cooker for confectionery products

Producing excellent confectionery products requires high quality cooking. Trad...

Pilot extruder for cereals and snacks

Small batches of product using high value ingredients are not economical or practical...

Laboratory scale cereal cooker

When developing new breakfast cereal products it is expensive and time-consuming to take your...

Breaker for baked granola sheets

Once baked in large sheets, granola needs to be processed into a final product. For premium...

Pre-conditioner for breakfast cereals

Extruded breakfast cereal products are a popular and lucrative product class. In case...

Cooked cereals shredder

By shredding cooked cereals, innovative breakfast and snack products can be created, including single...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...

Industrial pressure cooker

Optimizing production processes and human resources to reduce energy consumption and save time an...

Industrial sauce pan

For the small and medium food industry, economical use of time, space and human resources is critical wh...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...