Continuous extruder for protein bars and super foods

Optimize your snack production with a continuous extrusion solution that enhances efficiency, handling diverse compositions from nut pastes to protein bars, ensuring precise shaping and consistent quality ready for further chocolate coating and packaging.

Extrudes and Shapes Protein Bars and Nut Pastes

The Selmi Extruder offers a precise solution for crafting protein bars, nut pastes, and other confectionery items. Utilizing thermoregulated screw pumps, this equipment ensures consistent product extrusion with control over size and shape through an interchangeable 3-hole head. It accommodates various compounds like almond paste, ganache, and gianduja to create diverse end-products such as energy bars and chocolate-coated sweets.

With a production capacity of approximately 100/120 kilograms per hour, this continuous extruder integrates seamlessly with coating and cooling tunnels, optimizing the enrobing process. Its intuitive touch screen panel allows for swift adjustments in product format and extrusion speed, while the on-board refrigeration unit enhances efficiency by offering heated or refrigerated modes.

Designed for easy sanitation, it features removable heads and augers for quick changes between batches, supporting a wide range of confectionery needs. Whether you’re producing vegan chocolate ganache or spirulina bites, the Selmi Extruder is engineered for adaptability and high throughput, making it ideal for confectionery manufacturers and protein bar producers.

Benefits

- Boosts production efficiency with continuous extrusion and integrated coating options.

- Minimizes energy use through thermoregulated operations, offering heated or refrigerated modes.

- Enhances product consistency and flexibility with customizable extrusion settings.

- Streamlines cleaning and maintenance with removable components for quick batch transitions.

- Expands product range capability, accommodating diverse confectionery and nut paste formulations.

- Applications

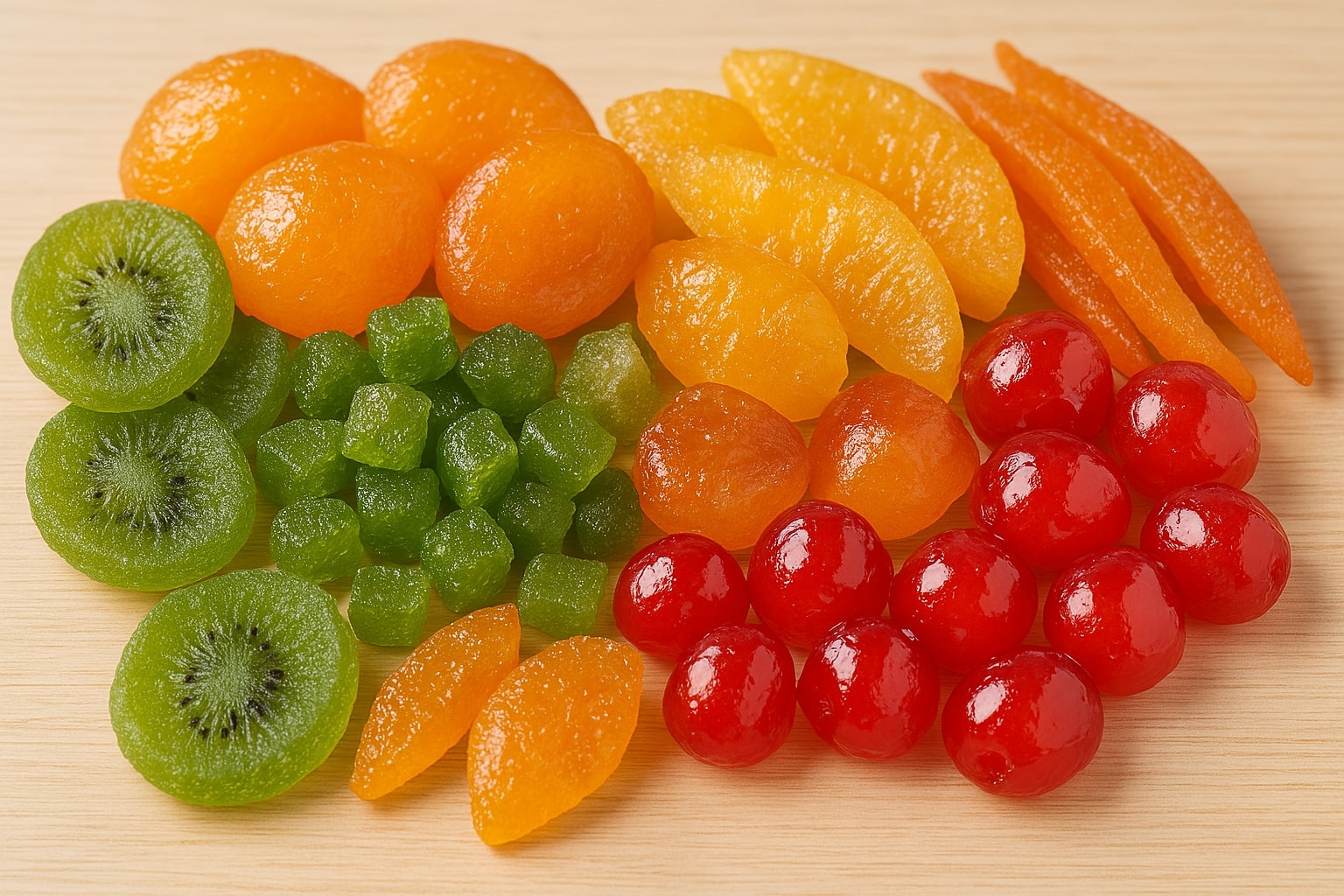

- Super foods, Nut compounds, Snacks, Date paste, Peanut paste, Confectionery, Ganache, Sweets, Hazelnut paste, Gianduja, Almond paste, Candied fruits, Nut pastes, Protein bars

- End products

- Energy bars, Milk chocolate gianduja, Vegan chocolate ganache, Pumpkin seed bars, Spirulina bites, Keto bars, Date energy balls, Protein bar bases, Chocolate pralines, Protein-packed snacks, Chocolate-coated sweets, Candied orange slices, Marzipan, Almond butter, Peanut butter, Hazelnut spread

- Steps before

- mixing, ingredient selection, compound preparation, manual product loading

- Steps after

- coating, cooling, decoration, packaging

- Input ingredients

- almond paste, ganaches, gianduja paste, date paste, candied fruit, peanut paste, hazelnut, nuts, protein bar compounds, super food compounds

- Output ingredients

- protein bars, super foods, almond paste products, ganache products, gianduja products

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Automation

- Intuitive touch screen panel

- Capacity

- 100/120 kg/h

- Power required

- 4 kW

- Power supply

- 400 V three phase - 50 Hz

- Dimensions

- 1540x1820x820 mm

- Cooling option

- Heated or refrigerated mode

- Cleaning method

- Easily sanitized and washable

- Extrusion speed

- Adjustable via touch screen

- Die configuration

- Interchangeable 3-hole head

- Automation level

- Intuitive touch screen panel

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easily sanitized and washable

- Changeover time

- Quick due to removable head and augers

- Energy efficiency

- High production, low energy use

- Abrasion resistance

- High

- Cleanability

- Easy to clean, removable head and augers

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Compatible with food products like protein bars and superfoods

- Density/particle size

- Compatible with pastes and similar consistencies

- Machine footprint

- 1540x1820x820 mm

- Discharge method

- Guillotine cut

- Control panel type

- Touch screen panel

- Cooling option

- Heated or refrigerated mode

- Control panel type

- Intuitive touch screen panel

- Integration possibilities

- Compatible with tempering machines, enrobing and cooling tunnels

- Interchangeable extrusion head

- 3-hole head

- Heating and cooling mode

- Heated or refrigerated mode

- Removable parts

- Removable head and augers for easy sanitization