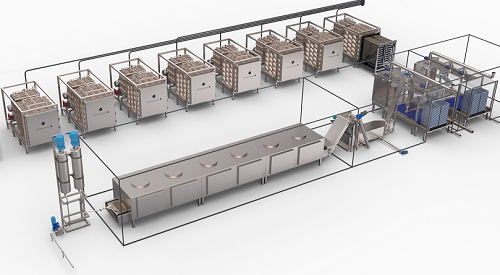

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it is essential to ensure that the products are stable, concentrated and have a good shelf life. There is a need for freeze dryers to have a capacity high enough to yield large quantities of the end product through batch production, such as capsules or fortifiers to be added to dried food.

Save costs with an increased capacity to freeze dry nutraceuticals

Siccadania’s FD500 offers an automated and continuous freeze drying production, by arranging several FD500 standard freeze dryer units in a system. The modularized and optimized FD500 standard module is perfectly prepared for the automatic loading and unloading of trays. It therefore requires no manual labour. The modules can be customised in a desired and suitable layout to reach your required output capacity. Its capacity can be increased or decreased easily, by adding or removing FD500 dryer units to or from the system. The automation system can handle up to 20 units.

The automatic freeze dry system is thus a cost efficient, high capacity solution which freeze dries your product while maintaining their chemical structure to confirm they still provide the expected health benefits. It is hygienic and easy to maintain making it suitable for freeze drying in the food, beverage and chemical industry and also of nutraceuticals and dietary supplements e.g. probiotic bacteria, colostrum, enzymes and allergen extracts.

Benefits

- Different products can be dried simultaneously making production flexible.

- The fully automatic system reduces the cost for manual labour and operating expenses.

- All equipment is designed based on the highest hygienic standards.

- Lower qualifying costs - the qualifying documentation for the first unit can be used as a template for the subsequent units.