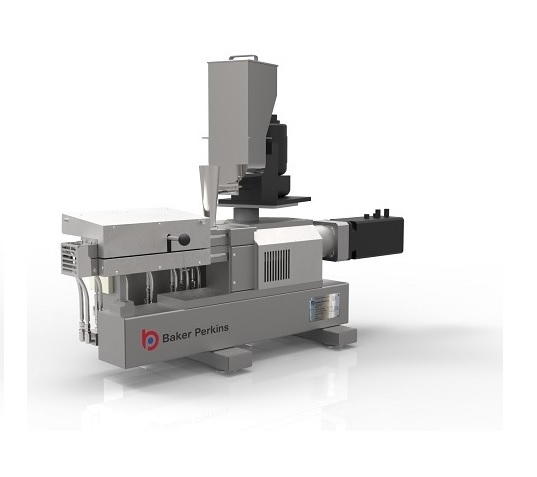

Benchtop extruder for cereals and snacks

Extruded products are very popular in the breakfast cereal and snack sectors. It is extremely inefficient to design, test and perfect new product ideas and recipes using full-scale production equipment. A high-quality lab-scale extruder is a vital tool both in product research and recipe design, and where results can be accurately scaled in production line design as well.

Benchtop extruder for research, troubleshooting, and quality assurance needs

The Baker Perkins MPF19 Benchtop Extruder is a high-quality twin screw extruder perfect for lab work, product design and process testing duties.

The MPF19 is equipped with the unique Baker Perkins “clam-shell” barrel. This allows the extruder to be halted at any stage and provides immediate access to check on the processed materials.

Designed with maximum flexibility for research and development, the MPF19 allows for quick and easy adjustment of formulation, all process settings, and all screw configurations. In addition, the screw configurations offer identical geometry to full-scale production extruders which makes the MPF19 perfect for recipe formulation and testing. Fully automated start-up and shutdown procedure also perfectly mimics the same systems available on production scale machines.

An integrated control system provides almost all the controls available in a production scale extruder, and provides storage for up to 50 recipes and full performance data capture. The MPF19 can be connected to a PC to allow data download for analysis and comparison.

Benefits

- Allows for the rapid testing of new product ideas for evaluation

- Perfectly scaled with full size production extruders means it can be used for process troubleshooting

- Effects of new ingredients or formulations can be tested without impacting main production

- Small form factor allows batch size as low as 5kg per hour, up to 25kg per hour

- Onboard touchscreen HMI for full recipe control and operational data