Cereal Bar Making Equipment

Find innovative production technology for making cereal bars and connect directly with world-leading specialists

The cereal bar production line consists of mixing, cutting and cooling a dough of chosen ingredients. These can be seeds, nuts, chocolate chips, dried fruits - and many more options. It may seem simple, but it needs attention to provide an appetizing look and taste.

Technology picks for cereal bars

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

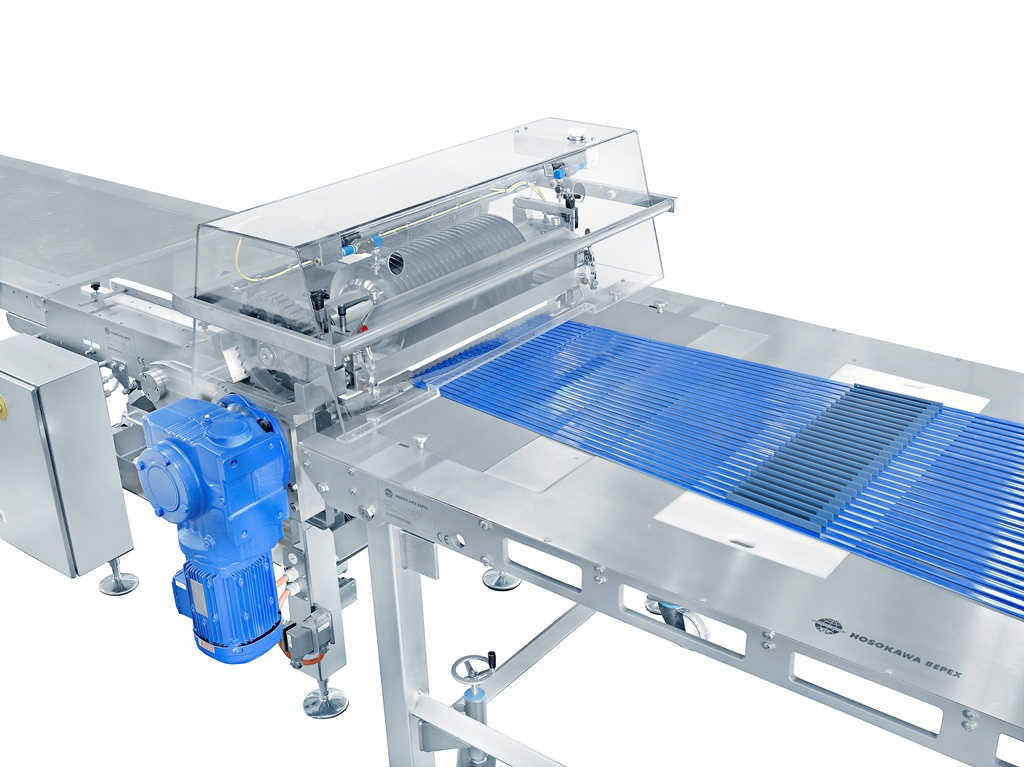

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

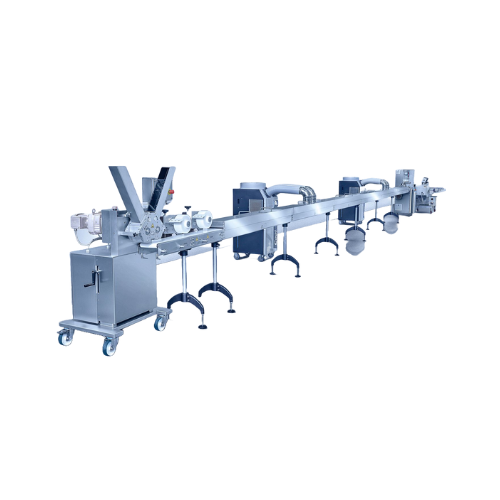

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Stories about cereal bars

Tell us about your production challenge

Setting up your cereal bar production line

The cereal bar production line starts with choosing and loading into the cooker the ingredients that will compose the bar. After that, the mixing process starts, usually with oil and sugar, to provide structure to the cereals. You can also try different liquids, such as syrup, honey, pureed dried apricots or barley malt syrup, to name a few. When you include the cereals to be mixed, you’ll also cook them. After that, you can roll the mix on a flat surface. Once you spread the dough, it is time to compress it to the desired dimensions, cut, cool and pack it. The whole production line can be automated or semi-automated; it is indeed possible to do some steps manually, for instance in beginners’ or small-scale productions.

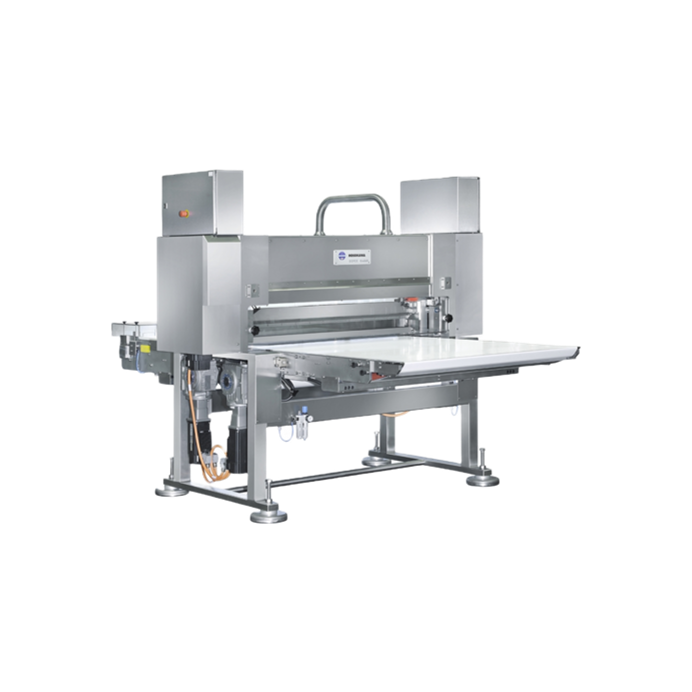

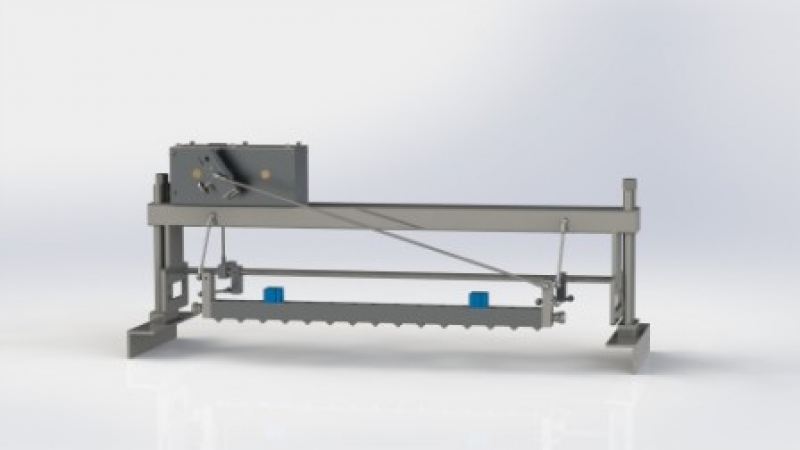

Rolling and cutting for small cereal bar production line

If you are starting your cereal bar production line, want to test a new recipe before scaling it or do not want to automatize the whole manufacture, you can use a manual plant for bars. In it, you have a table with a cooling and warming system, over which you can pour and disperse the cooked dough, whether you have mixed it or not. There, it is compressed and transformed into the final bar shape with the use of a manual guillotine cutter with blades.

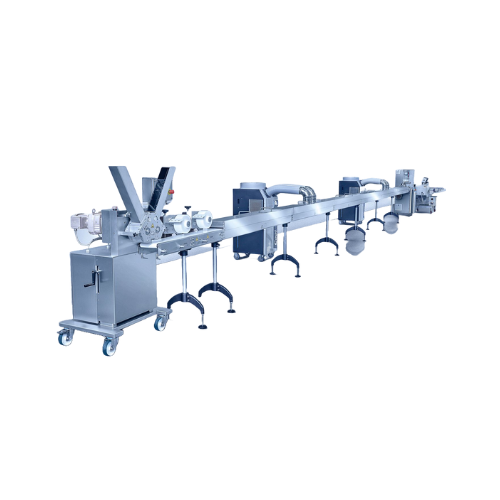

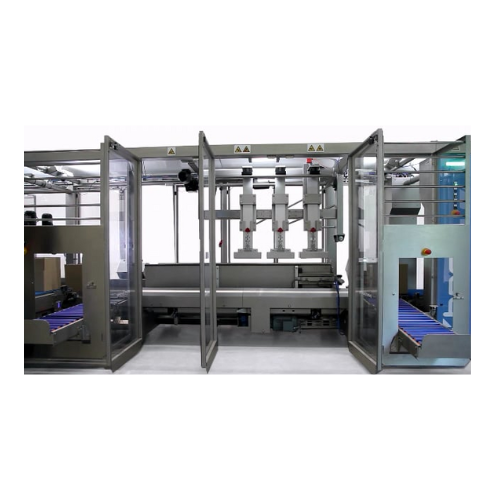

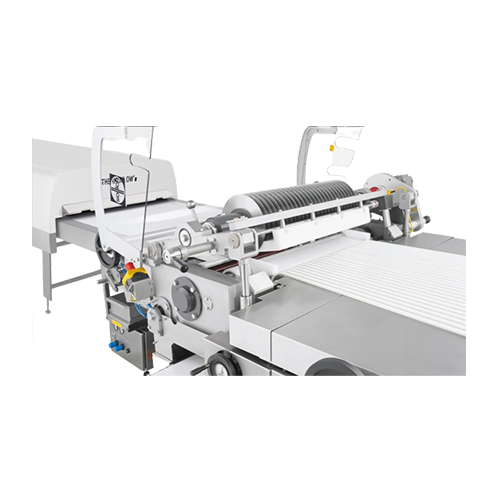

Automatic cereal bars processing option

You can also opt for an automatic plant. In this one, the equipment mixes, doses and cuts the cereal bar in the desired size and format. You need to include the cereal mix and to prepare and fill the vessel with a binder. You can adjust the manufacturing to your production specificities. They may be the cutting speed, for instance, or the bar size.

Packaging, the wrap up of your cereal bar production line

To help build a brand positioning and influence in the product purchase, you may consider an appealing packaging design. Fully customizable solutions adjust to product line specifications – in terms of size or shape, for instance. You can also use equipment that includes the application of seal foils. They are important because, among other things, they can extend the product’s shelf life and provide more safety to atmospheric changes. These foils also resist vibration damage and high or low-temperature variation.

Processing steps involved in cereal bars making

Which cereal bars technology do you need?

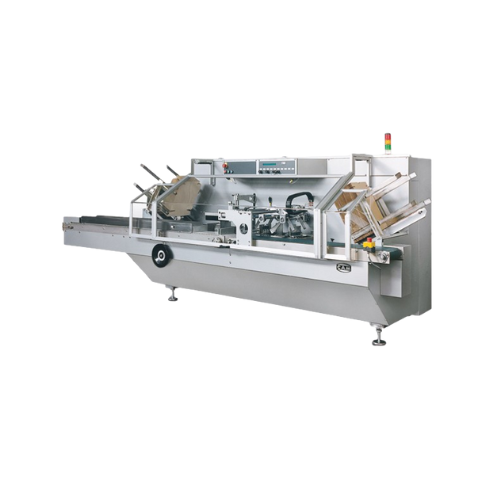

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Chocolate storage tank

Optimize your chocolate production with seamless storage solutions that ensure consistent quality and ...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Figure moulding for pliable mixes

Transform pliable mixtures into intricate 3D figures with precision and efficiency, cater...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Intermediate container for raw material preparation

Streamline your snack and cereal production with this solution that e...

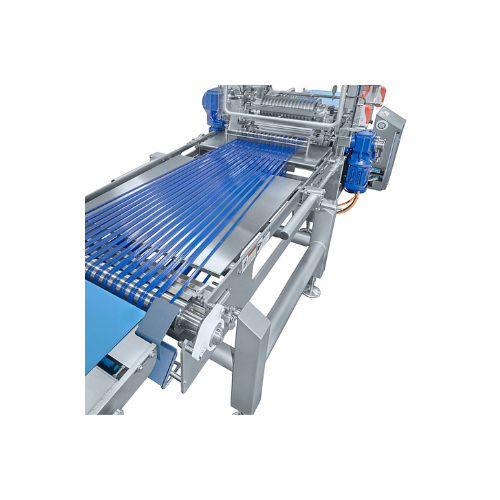

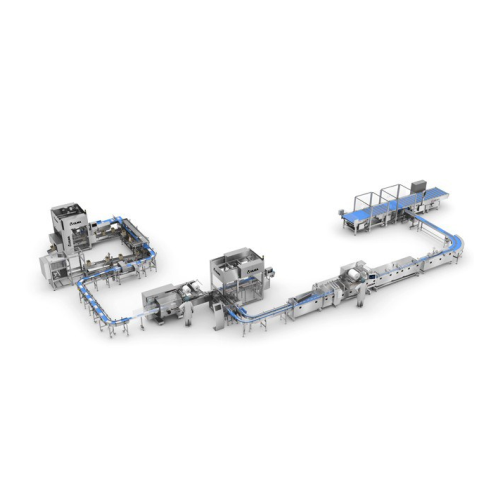

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

Inline grinding system for sausage and minced meat production

Streamline your production line by simultaneously grinding...

High-pressure vacuum filler for industrial sausage production

Effortlessly tackle high-pressure demands in sausage produ...

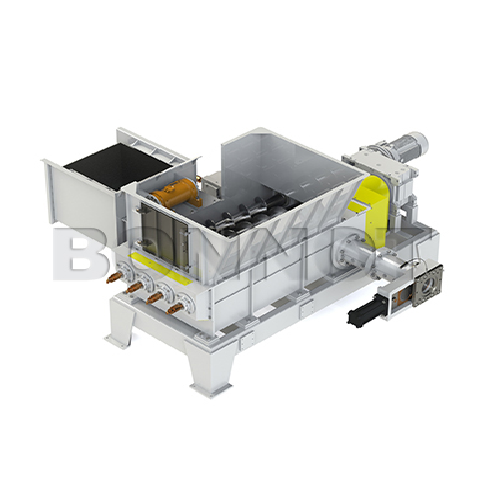

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

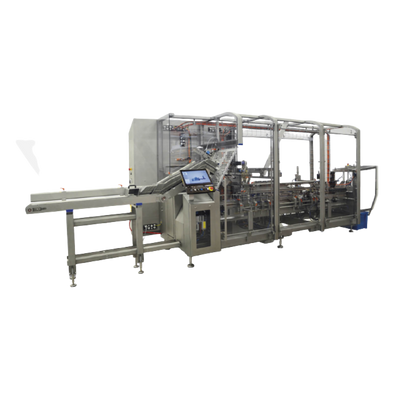

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

Full Rsc case shaker-compactor-sealer

Streamline your packaging line with a solution that compacts and seals cases to elimi...

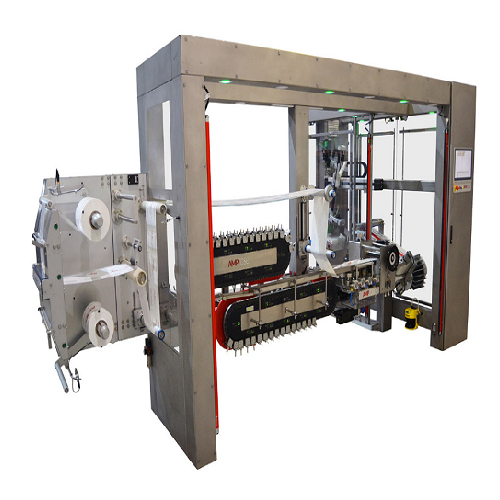

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Industrial screw pump for dosing hard fillings

Enhance precision and efficiency in dosing hard fillings with a robust scre...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Automated packaging and case packing for snack bars

Optimize your snack bar production line with this high-speed solution...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

Combined metal detector and checkweigher

Ensure compliance and product safety in food production with an integrated system ...

Live bottom extruder for processing sealants and mastics

Efficiently integrate entire material batches into your producti...

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

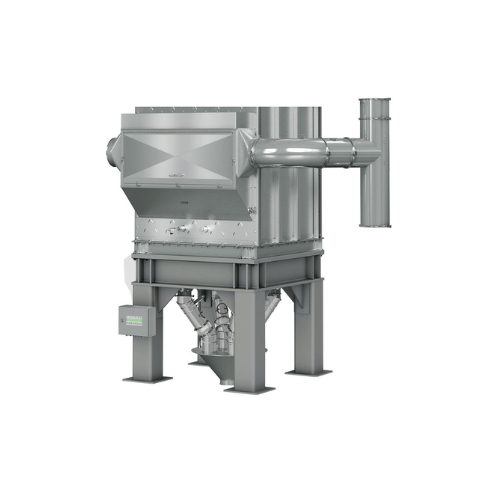

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

Single feeder operator interface for gravimetric feeders

Enhance precision in your dosing operations with an intuitive to...

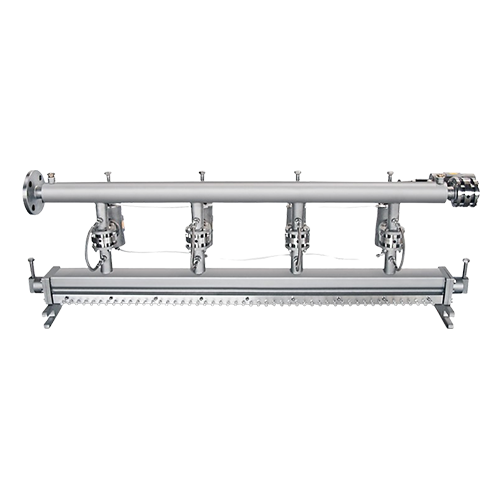

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

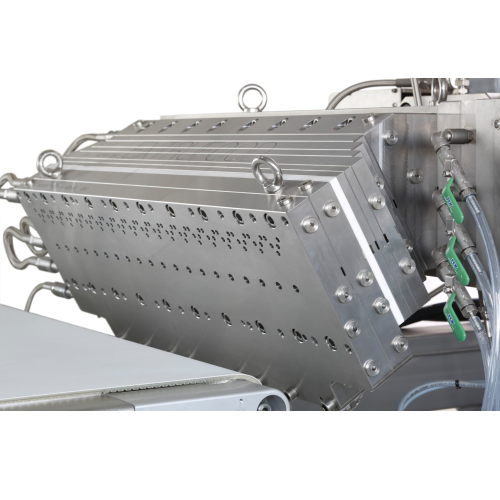

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Bottom coating system for confectionery production

Optimize your confectionery line with precision bottom coating, ensuri...

Compact carton blank feeding system

Maximize your production efficiency with a solution designed to streamline carton blank...

Cartoning Machine For Snacks and Sweets

When producing different snacks and sweets, each product will match a different car...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Multi-nozzle chocolate decorator

Make zigzag, corner, or loop designs on your enrobed products.

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for 3 masses

Form three ingredient mixes into the shapes and layer combinations required for your fi...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

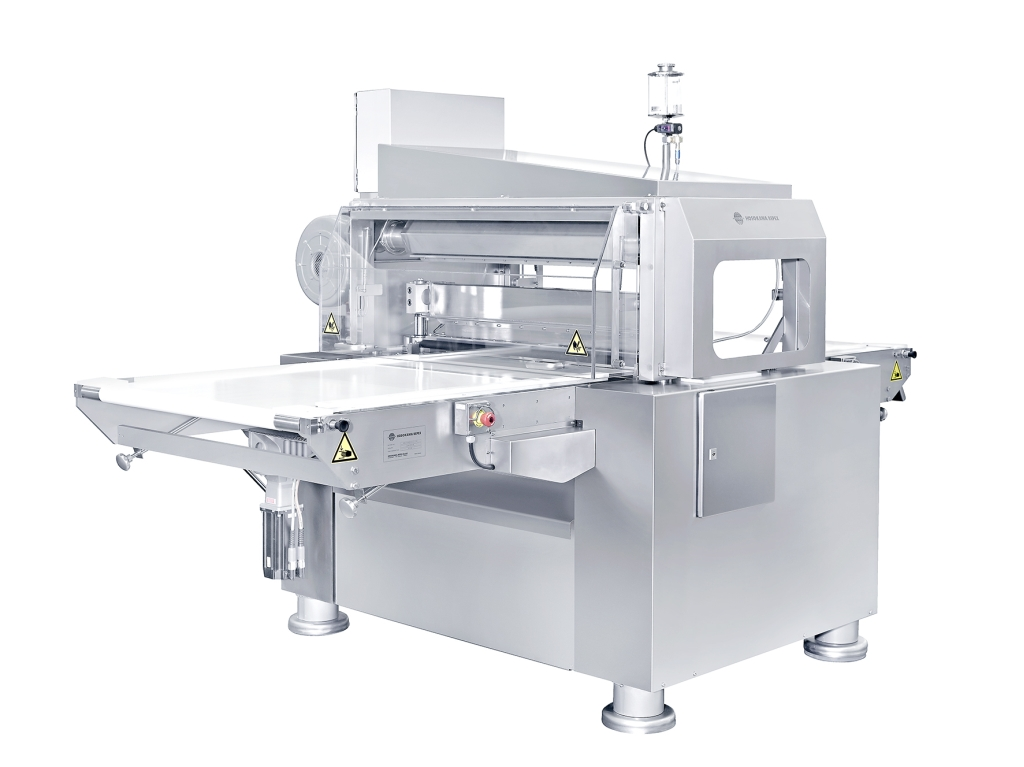

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

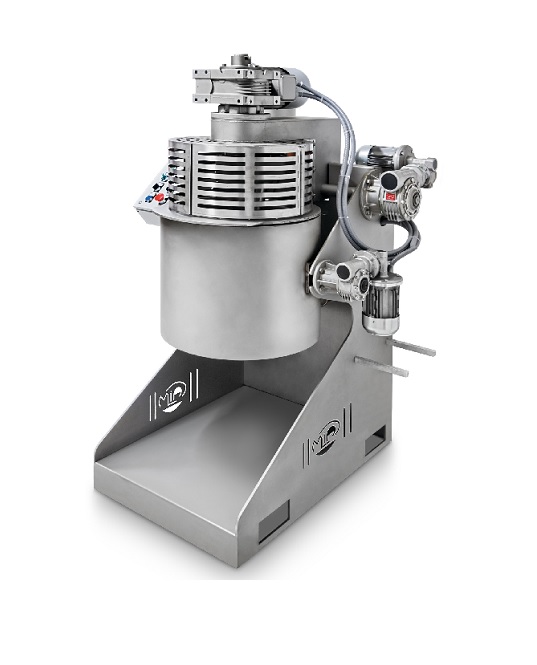

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

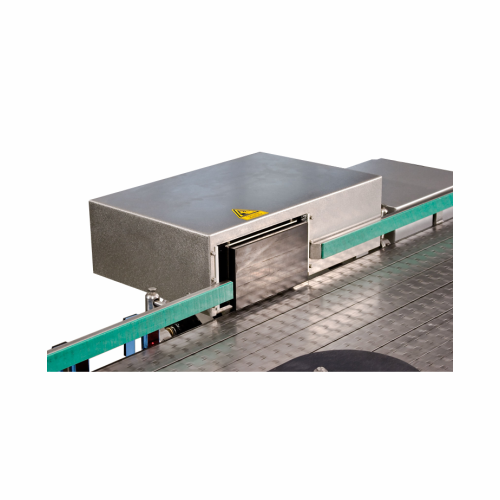

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...