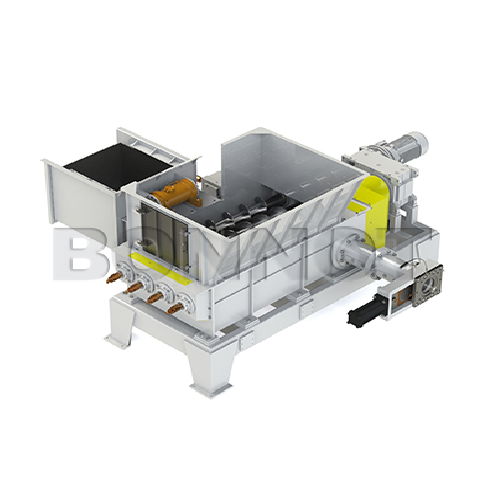

Live bottom extruder for processing sealants and mastics

Efficiently integrate entire material batches into your production line while maintaining precise temperature and feed control, eliminating pre-sizing costs and enhancing quality consistency for diverse end-products.

Processes and Loads Sealants and Mastics Efficiently

The RS 6 Series LB and RS 8 Series LB Live Bottom Extruders from The Bonnot Company are engineered to streamline batch processing workflows, tackling the challenge of efficiently handling entire loads of diverse materials—ranging from sealants and mastics to industrial rubber and food products. This equipment stands out with dual-drive technology that independently controls feeding and extrusion, providing unparalleled precision in material handling.

With customized feed beds and multiple temperature zones, including screw temperature control, the Live Bottom Extruder ensures consistent output and optimal material properties. It processes applications such as butyl sealant strips, automotive mastics, and cereal bars, supporting capacities from 1,000 to 4,500 lbs/hour, depending on the model. The extruder’s design incorporates high torque motors and a hydraulic batch loading system for seamless integration into your production line.

The RS Series features jacketed barrels for enhanced temperature regulation, while its flexible configuration—right or left-hand orientation—accommodates various facility layouts. The extruders are suitable for chemical, food, rubber, and sealant industries, offering robust construction with optional material and corrosion-resistant finishes. Simplified maintenance and customizable options ensure these extruders meet specific operational demands and production goals efficiently.

Benefits

- Eliminates pre-sizing costs, streamlining batch processing for increased efficiency.

- Dual-drive system provides precise control over feeding and extrusion, enhancing product consistency.

- Customizable configurations fit seamlessly into existing layouts, reducing installation complexities.

- Energy-efficient operation due to optimized motor control, minimizing operational costs.

- Facilitates high-capacity processing, supporting up to 4,500 lbs/hour depending on the model.

- Applications

- Sealants, Mastics, Butyl, Food forming products, Firelogs, Rubber, Rodenticides

- End products

- Firelog briquettes, Automotive mastics, Industrial rubber sheets, Cereal bars, Rodenticide pellets, Butyl sealant strips, Pasta shapes

- Steps before

- Mixing, Batch Loading

- Steps after

- Feeding, Temperature Control, Extrusion

- Input ingredients

- Butyl, Sealants, Mastics

- Output ingredients

- Processed Sealants, Extruded Material

- Market info

- The Bonnot Company is known for its expertise in manufacturing industrial extruders and cutting equipment, specializing in engineered-to-order solutions for various industries, including food, chemical, and ceramic sectors, with a reputation for quality and innovation.

- Output

- 1, 000 - 4, 500 lbs/hour

- Approximate Layout (RS 6 Series)

- 124” x 105” x 108”

- Approximate Layout (RS 8 Series)

- 190” x 128” x 59”

- Hopper Opening (RS 6 Series)

- 48” x 36-1/4”

- Hopper Opening (RS 8 Series)

- 86-1/8” x 48”

- Motor Power (RS 6 Series)

- 25 HP / 75 HP

- Motor Power (RS 8 Series)

- 40 HP / 100 HP

- Feed Screw Diameter

- 8"

- Batch Size Compatibility

- Customized

- Temperature Zones

- Multiple with Screw Temperature Control

- Hydraulic Batch Loading

- Optional

- Torque

- High Torque Feeder and Extrusion Motor

- Configuration

- Right or Left-Hand

- Batch vs. continuous operation

- Batch

- Automation level

- Dual drives for independent control

- Temperature control

- Multiple temperature zones

- Loading method

- Hydraulic batch loading

- Configuration options

- Right or left-hand configurations

- Temperature Range

- Multiple temperature zones

- Batch size compatibility

- Variable based on custom configuration

- Loading configuration

- Hydraulic / Manual Batch Loading

- Machine Footprint

- 124” x 105” x 108” / 190” x 128” x 59”

- Feed Method

- Batch loading with optional hydraulic feature

- Discharge Method

- Live bottom extrusion

- Hopper Opening Size

- 48” x 36-1/4” / 86-1/8” x 48”

- Temperature Zones

- Multiple, including screws

- Screw Diameter

- 8"

- Hydraulic Batch Loading System

- Optional

- Temperature Zones

- Multiple

- Feed Bed Size

- Customized to match batch size

- Configuration

- Right or Left-Hand

- Extruder Designs

- Different extruder designs available

- Screw Temperature Control

- Rotary Union