Adhesives Manufacturing Equipment

Find innovative adhesives equipment and connect directly with world-leading technology suppliers

Adhesives are grouped according to their form, origin - natural or synthetic - and their material joining method. You can make natural adhesives from plant and animal sources such as bones, hide and skin, agar, dextrin. Manufacturers count with adhesive making equipment to produce synthetic adhesives from organic compounds. They include epoxy adhesives, cyanoacrylates (or super glue), acrylic adhesives and so on.

Stories about adhesives

Select your adhesives process

Tell us about your production challenge

Reactiveness: when adhesives need special conditions for bonding

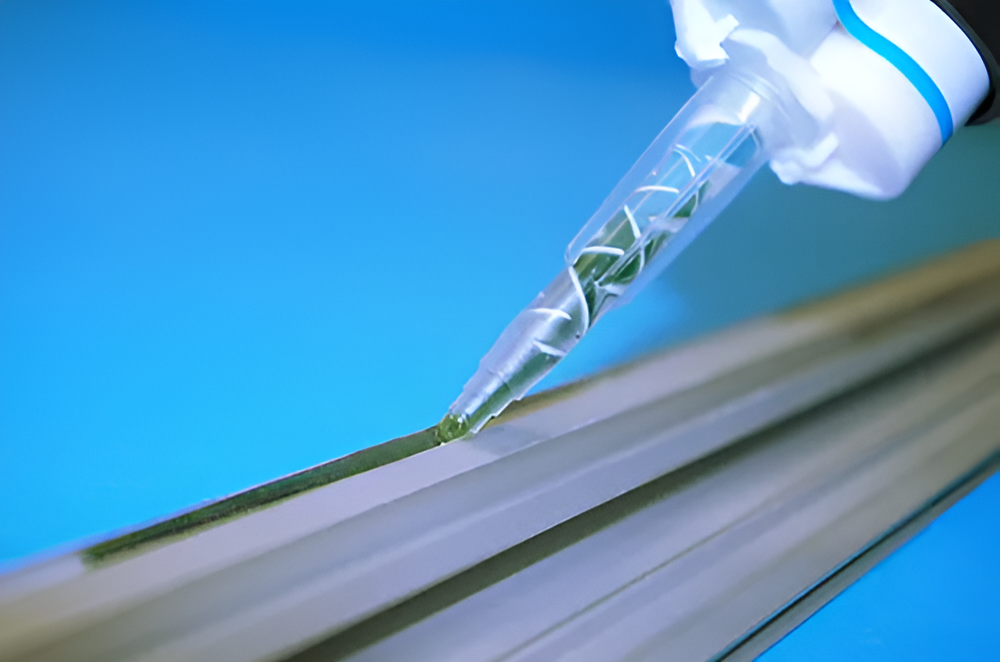

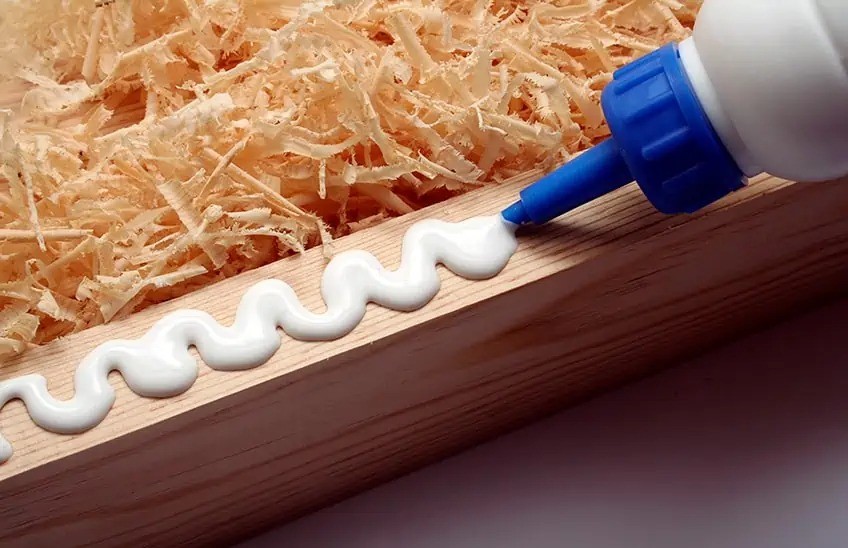

Further classification of adhesives involves their method of reaction. This implies that they may or may not need chemical reactions to harden. Reactive adhesives bond in the presence of a reactive catalyst like heat, moisture and absence of oxygen to solidify. Non-reactive adhesives harden by drying. Acrylic adhesive is reactive and you can produce it by the reaction of acrylic and methacrylic acids in the presence of a special activator, which initiates bonding. An acrylic reactor for helps get a better yield. Hot glue making can happen with batch processing, using a kettle mixer, for instance, or continuous extrusion. Adhesive making equipment automates large scale production.

Industrial production: how the adhesive making equipment design helps make quality adhesive

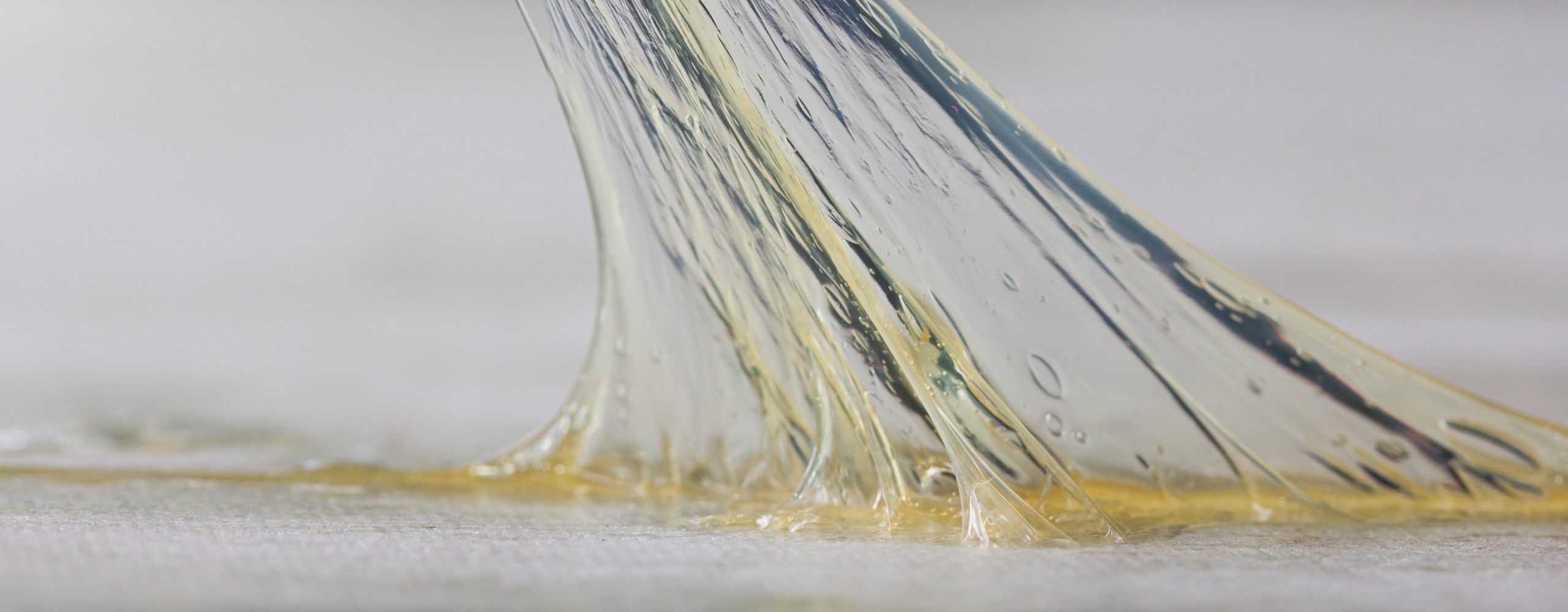

Solvent-based adhesives are suitable for different kinds of substrate, which explains their vast application in the manufacturing industry. You can use it in the medical industry, the packaging industry and for automobiles. Solvent- and water-based adhesives are both beneficial to manufacturers depending on their application. The former dries very quickly because they are made with hydrocarbon solvent such as acetone and toluene.

Asides from prolong drying time of water-based adhesives, they are safe and cheaper than the solvent-based. You can produce water based adhesives by combining water, polymers and additives. For solvent-based adhesives, mix solvents and thermoplastics such as acrylic or silicone. Use a high shear mixer to help you with that. It subjects the ingredients to intense high energy to make a stable and fine emulsion.

How do adhesives impact the environment – and are there alternatives?

The biodegradability of solvent-based adhesives is significantly low. The chemical wastes are not eco friendly and, as such ,affect the soil, water and air. A good number of manufacturing industries produce solvent-based adhesives because of their high substrate affinity.

Consider sustainable options like beeswax or gum arabic in place of non-renewable adhesives. Gelatin, an animal collagen, is biodegradable, but involves different manufacturing process and equipment other than adhesive making machine. It usually involves pre-treatment with acid (hydrochloric acid) or alkaline (sodium carbonate) to remove minerals and impurities. The extraction kettle can help you with that. Countries like the United States do not allow the use of solvents like toluene and methylene chloride when producing adhesives due to their negative environmental impact.

From ceramics to packaging – trends in the adhesive market

The global hot melt adhesive market reached a value of US$ 6.75 billion in 2020. Looking forward, the market is expected to grow at a CAGR of 4.5% during 2021-2026. The packaging sector is growing and steadily driving the demand for hot melt adhesives. Asides from sealing purposes, the automobile industry uses it for car seat covers. Other rising demand includes flooring materials and ceramics. Apart from looking for better adhesive processing equipment, producers also regard the cost-effectiveness of making adhesives. Also, instead of oven drying or ultraviolet curing, manufacturers are opting for the Ebeam technology, which doesn’t produce volatile organic compounds (VOCs).

Which adhesives technology do you need?

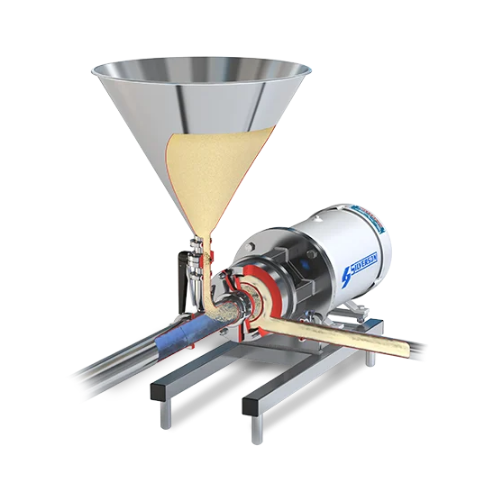

Continuous kneader for viscous applications

For engineers tackling high-viscosity challenges, this continuous kneader stre...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Dispersing system for high-viscous products

Achieve precise mixing and dispersing of high-viscous products with advanced f...

Mixing and dispersing solution for ultra high-viscous products

Efficiently process ultra high-viscous and thixotropic ma...

High-efficiency disperser for viscous products

Achieve precise control over the mixing and dispersing of high-viscosity ma...

Explosion-proof production vacuum disperser for viscous products

Achieve precise and reliable dispersion of high-viscosi...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

Vacuum dissolver for highly viscous products

Efficiently mix and disperse high-viscosity substances under vacuum to ensure...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

Explosion-proof basket mill for large scale production

Enhance your production line with an explosion-proof basket mill t...

Efficient high-volume dissolver with scraper

For high-viscosity formulations, this advanced dissolver with integrated scra...

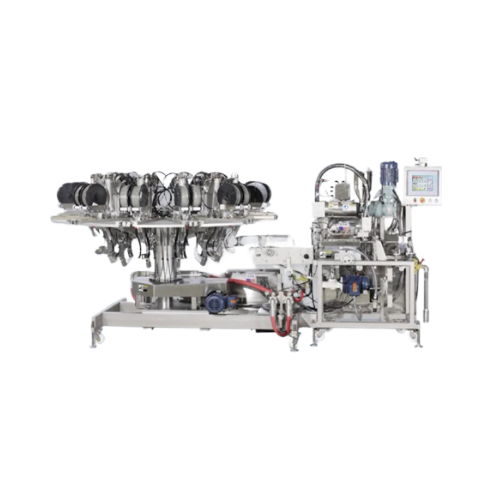

High-precision material coating for bore holes and internal threads

Achieve consistent, high-precision coating in bore ...

Homogenizer for low to medium viscosity media

Achieve uniform mixing and prevent air entrapment in low to medium viscosity...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

Aerator for high-viscosity media

Highly viscous ingredients in both the food and chemical processing industries require spec...

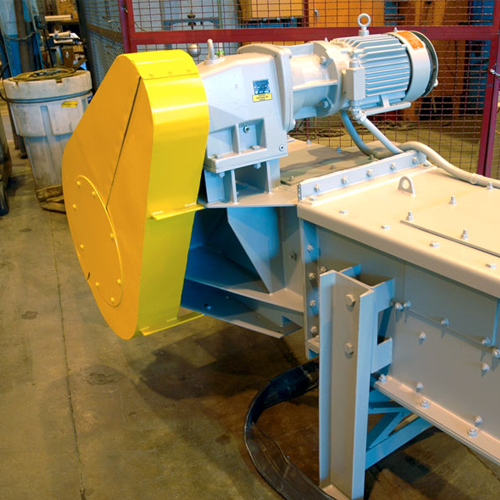

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Explosion-proof rotary vane vacuum pump

Ensure safety and efficiency in flammable environments with this explosion-proof va...

Cone calorimeter for fire testing and safety engineering

Ensure safety in your materials by precisely measuring combustio...

Guarded hot plate for thermal conductivity testing

Ensure optimal insulation performance with precise thermal conductivit...

Nanoparticle size analyzer

Master precise nanoparticle and zeta potential analysis with dynamic light scattering technology,...

Zeta potential analyzer for colloidal stability

Achieve precise control over colloidal stability and particle interactions...

Ultra high temperature treatment for small-scale production

Achieve extended shelf life and uniform product quality with...

Industrial robot for arc welding and adhesive applications

Optimize your production line with precise and high-speed rob...

Robotic arm for small component handling

Streamline your production with a versatile robotic arm designed for small compone...

Continuous-path arc welding robot

Optimize your production line with high-speed, precision arc welding using our advanced h...

Adhesive nozzle cleaning system for automotive production

Ensure consistent adhesive application and seamless quality by...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

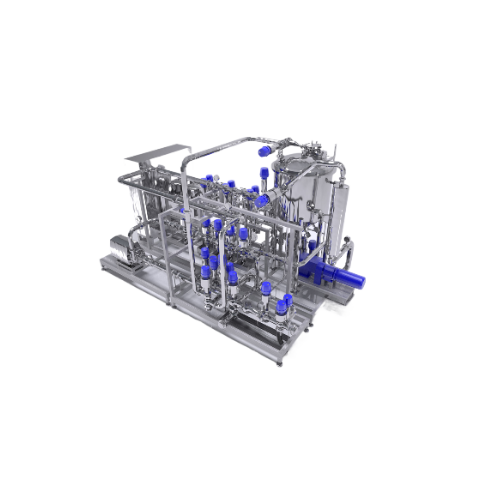

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Gravimetric dosing systems for precise material measurement

Achieve precise material measurement with gravimetric dosing...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

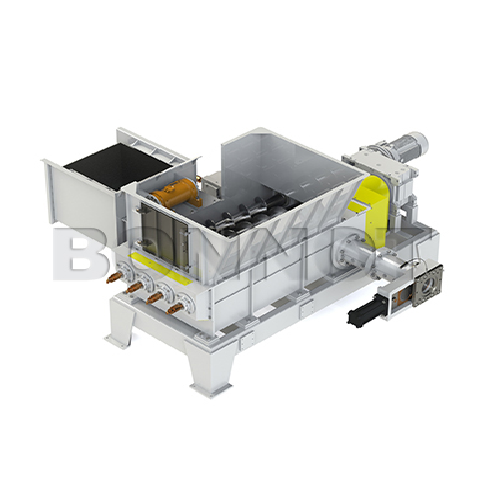

Horizontal paste mixer for high-viscosity materials

Efficiently transform high-viscosity and challenging materials into u...

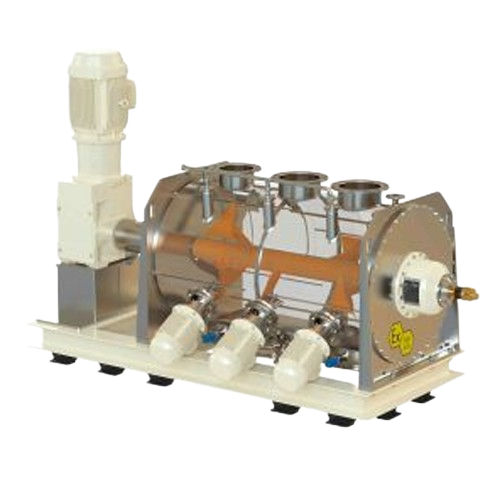

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Coating centrifuge for small parts with oil and adhesives

Optimize your coating processes with a centrifuge designed to ...

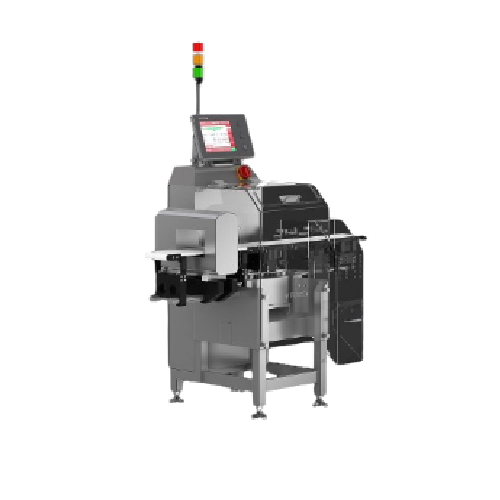

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Side entry mixer for industrial fluid mixing

Optimize your fluid mixing processes with high-speed side entry mixers, desig...

Universal industrial agitator for various fluid mixing needs

Optimize your production with an industrial agitator design...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

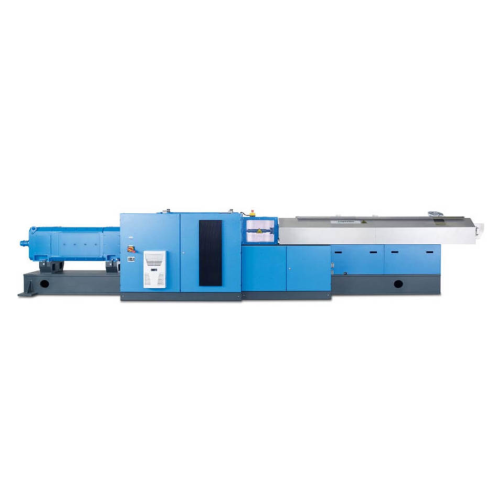

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Laboratory vacuum mixer reactor for liquids and semi-solids

Achieve precise emulsification and mixing for high-viscosity...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

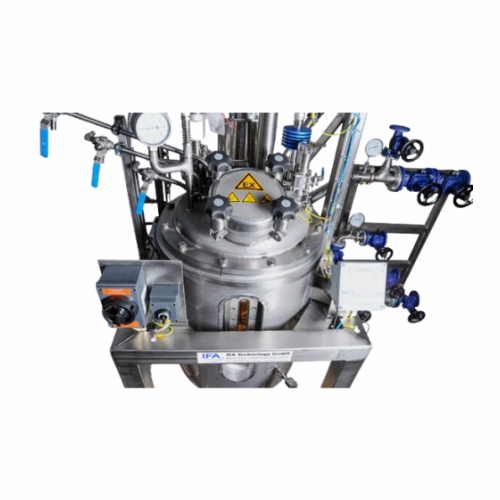

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

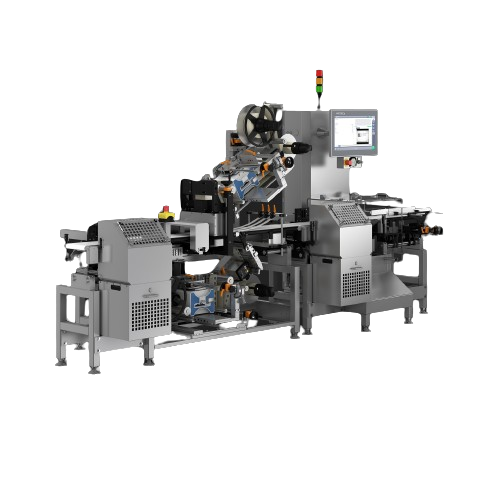

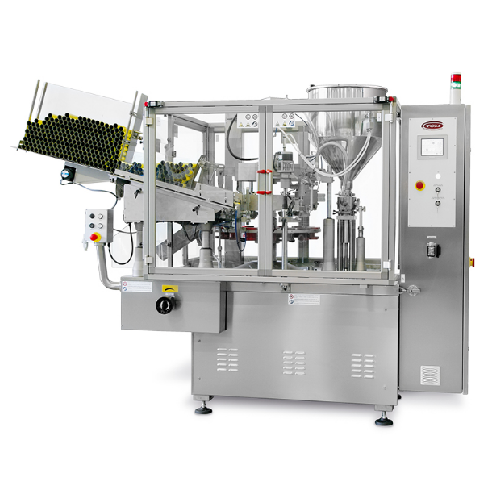

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Automatic single side adhesive labeling solution

Streamline your packaging line with precision; this solution offers effic...

Double sides adhesive sticker labeling solution

Achieve seamless and precise double-sided labeling on bottles and containe...

Indirect drying drums for solvent-based products

Optimize energy use and safety with our indirect drying drums, ideal for ...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Dual asymmetric centrifugal processing system for epoxies and slurries

Streamline complex formulations with a system th...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Automatic labeler for low profile containers

Optimize container labeling with precision and efficiency, addressing the cha...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Automated clipping system for flexible packaging

Achieve precise volume control and reduce material waste with this high-s...

Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with conti...

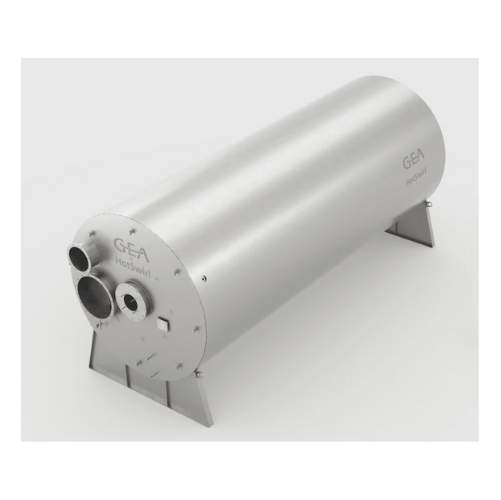

Industrial hot air system for spray dryers

Ensure consistent hot air delivery for critical drying processes, enhancing ene...

R&d spray drying solution for small batch production

Efficiently convert liquid solutions into precise, uniform powders f...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Integrated x-ray, checkweighing, and vision inspection unit

Ensure product safety and compliance by seamlessly detecting...

Modular end-of-line system for quality control

Streamline your end-of-line operations with seamless integration of weighin...

Compact x-ray scanner for foreign body detection

Ensure product quality with a space-saving x-ray scanner designed for hig...

Checkweighers for accurate weight control in production

Ensure precise weight compliance and complete data acquisition th...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Checkweigher with integrated metal detector for food industry

Ensure comprehensive quality control in your production li...

Processing vessel for liquid, sauce, or cream products

Efficiently mix and integrate liquid, cream, or slurry products wi...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for homogenous mixing of powders and pastes

Achieve rapid and precise mixing with high-speed dispersion...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Twin shaft mixers for fragile and high throughput applications

Maximize mixing efficiency and protect delicate materials...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Laboratory mixers for product development and research

Optimize your R&D efforts with advanced mixing solutions desi...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

Dissolver for high-viscosity products through floor installation

Optimize production of ultra-high viscosity products wi...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Top-mounted disperser for high-viscosity products

Achieve rapid, uniform dispersion of ultra-high viscosity materials wit...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

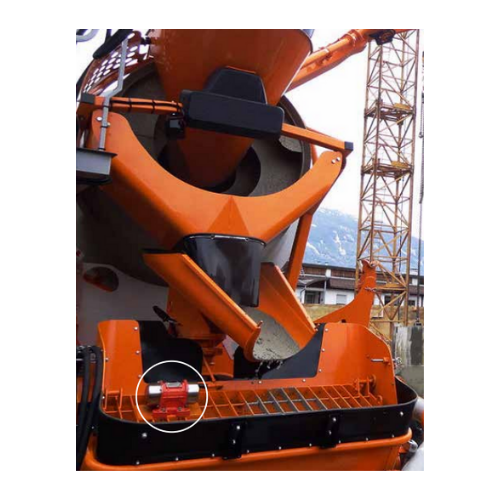

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Pneumatic actuators for industrial valves

Optimize valve control in your production line with precision-engineered actuato...

Industrial mixing dissolver for medium to large batches

Achieve precise mixing and dispersion of medium to large batch fo...

Explosion-proof dissolver for production applications

Ensure safety and efficiency in volatile environments with a robust...

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

High-performance dissolver for large-scale production

Optimize your production line with precision-controlled dispersion ...

Vacuum basket mill for high-viscosity product processing

Achieve exceptional fine milling results while preventing air in...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Vacuum disperser for high-viscosity products

Optimize high-viscosity product dispersion and prevent air inclusions with a ...

Vacuum dissolving system for high-viscosity products

Achieve flawless dispersion of high-viscosity substances under vacuu...

Production dissolver for high-viscosity products

Achieve optimal dispersion and grinding of high-viscosity substances with...

Rotary homogenizer for high shear mixing

Achieve precise homogenization of various viscosities with advanced rotor-stator t...

Rotor-stator homogenizer for high shear batch processing

Achieve ultra-fine particle distribution and stable emulsions wi...

Explosion-proof horizontal bead mill for paint production

Ensure ultra-fine particle size and consistent quality with an...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

High-capacity dissolvers for industrial mixing

Enhance your production line with precision mixing, achieving consistent di...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

High-efficiency immersion mill for medium viscosity products

Achieve precise particle size reduction and superior disper...

High-efficient industrial immersion mill

Achieve rapid, efficient dispersion and fine grinding in demanding production envi...

High-performance dissolver for industrial dispersion processes

Optimize your dispersion processes with this advanced dis...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Dissolving system for high-viscosity products

Optimize the dispersion of high-viscosity liquids and pastes with this versa...

Production dissolver with scraper for high-viscosity products

Efficiently tackle high-viscosity material processing with...

Industrial dissolver for high viscosity products

Optimize high-viscosity product dispersion with a robust dissolver design...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

Explosion-proof dissolver for high-viscosity products

Optimized for safely processing high-viscosity products, this explo...

Explosion-proof dissolver for high viscosity products

Optimize your high-viscosity material processing with an explosion-...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high-viscosity products

Optimize your production by eliminating air inclusions and ...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Vacuum dispersion system for laboratory applications

Achieve precise mixing and homogenization under vacuum conditions, e...

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion s...

Laboratory vacuum dissolver

Experience precision vacuum processing for your high-viscosity formulations, ensuring optimal di...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Dissolver for high-volume industrial dispersion

Achieve precise and efficient mixing with this dissolver, designed for sea...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Explosion-proof dissolvers for laboratory use

Ideal for safely dispersing and mixing chemical substances in potentially ex...

Lab stirrer for high-viscosity substances

Need precise, high-torque stirring for your complex formulations? This lab stirr...

Two-component static-dynamic mixer for high-viscosity materials

Simplify the challenging task of mixing two-component ma...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Laboratory bead mill for sample dispersion

Ensure precise particle size reduction with versatility and ease, enabling effi...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Nano bead mill for laboratory wet grinding

Achieve ultra-fine particle dispersion and consistent milling results with this...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Laboratory disperser for small batch processing

Achieve precise dispersion and homogenization of high-viscosity mixtures w...

Modular dispenser for dosing adhesives and abrasive media

Streamline your production line with a modular dispenser desig...

Precision 2k dispenser for automated systems

Achieve precise mixing and dispensing of two-component materials with minimal...

Dispenser for reactive material applications

Ensure precise dispensing of reactive materials without metal contamination, ...

Precision dispenser for high-viscosity fluids

Achieve unparalleled precision in dosing and application with a dispenser de...

3d print head for high-viscosity fluids and pastes

Enhance your 3D printing capabilities by reliably handling high-viscos...

Two component dispensing and meter mixing system for small quantities

Achieve precision and consistency in microdispens...

High-precision dosing systems for aerospace applications

Achieve unmatched precision and reliability when dosing complex ...

Industrial stativ mixer with adjustable height

Achieve precise mixing and stirring across diverse batches with a mobile, a...

Laboratory stirrer for high-viscosity materials

Streamline your laboratory mixing processes with a powerful stirrer design...

Industrial mixer for product-critical processes

When dealing with high-hygiene requirements and complex mixing tasks acros...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Compact high-torque extruder for customizable extrusion tasks

Ensure precise control over your extrusion processes with ...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Live bottom extruder for processing sealants and mastics

Efficiently integrate entire material batches into your producti...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Small batch tube filling system for metal and plastic tubes

Optimize your small-batch production with precise tube filli...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

Real-time trace gas analyzer for Voc detection

Achieve real-time, multi-analyte detection of volatile organic compounds an...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Portable and fixed mount mixing system

Optimize your mixing operations with a versatile system that adapts seamlessly betwe...

Powder/liquid mixing system for homogeneous dispersions

Struggling to integrate challenging powders into liquid formulati...

High shear batch mixer for industrial mixing

Optimize your production cycle with this high shear batch mixer, designed to ...

Disintegrator/dissolver mixing system for large solids

Streamline your process by transforming large, challenging solids ...

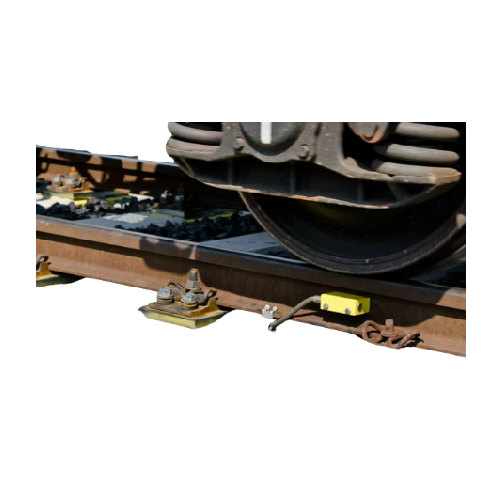

Pit scales for industrial weighing

Optimize material flow and ensure precise load determination with a robust pit scale sol...

Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide lega...

Scale hopper for bulk solid material handling

Ensure precise measurement and efficient transport of bulk solid materials w...

Crane scales for precise weighing in chassis

Optimize space with low-profile crane scales, ensuring accurate weight measur...

Crane weighing system for precision measurement

Ensure precise and temperature-resistant weighing during high-demand opera...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Bin weighing system kits for precise weight control

Ensure accurate material measurement in challenging environments with...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Ultrafine powder mill for coatings and pigments

Optimize your ultra-fine powder production with this precise grinding and ...

Solids flow meter for bulk solid streams

Ensure precise bulk material measurement with a system designed for accuracy and r...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Apron weighfeeder for sticky bulk materials

Optimally handle challenging, sticky materials with precision and consistency ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Loss-in-weight feeder for poor flowing bulk solids

Efficiently handle poorly flowing bulk solids with unparalleled precis...

Multipurpose feed station for bulk solids

Optimize your production line with a versatile feeding station designed for simu...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

En-masse chain conveyor for bulk material handling

Streamline your bulk material handling with a gentle, efficient system...

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in de...

Compact palletizer for food and beverage products

Optimize your end-of-line operations with a space-saving palletizer tha...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Conditioned seed drying machine

It’s essential to dry moist seeds before you process and store them. Seeds with too high or ...

Tray erector

Corrugated trays come in many forms and sizes. Automate the process of erecting the trays to ensure consistent q...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Tray former for various tray formats including trays with corner constructions

If you are looking to increase your sup...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Automatic can sealer

If you need to cap paint, glues, and solvents containers and are currently manually placing the lids, yo...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Airshocking hammer

Silos, hoppers, bins, and other containers can build up a layer of powdered product on the internal walls....

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Lid applicator for corrugated cases

For your secondary packaging, you may be considering packing into boxes that require a ...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...