High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear efficiency, ideal for demanding applications that require fast incorporation rates and reduced aeration.

Incorporates and Mixes Powders into Liquids

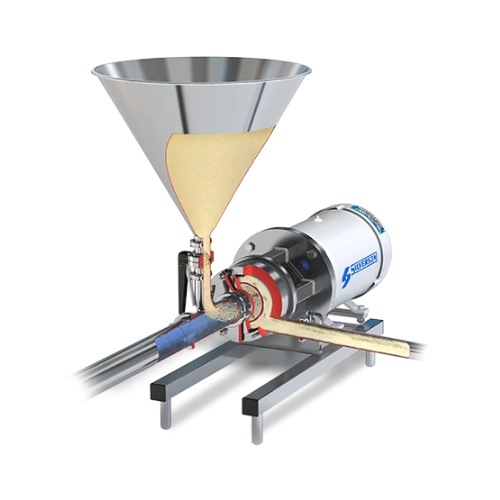

The Silverson Flashmix is an innovative high shear powder/liquid mixer designed to address the challenges of efficient powder incorporation. This cutting-edge equipment forces powders into liquid streams, unlike conventional vacuum-based systems, offering robust performance in high-viscosity and high-temperature processes. Ideal for industries ranging from biopharmaceuticals to food and beverage, the Flashmix ensures agglomerate-free mixing, producing consistent and uniform end-products like protein powders, enzyme solutions, and flavored beverages.

Capable of incorporating powders at rates up to 500 lbs/min, the Flashmix is adaptable for batch and continuous operations, handling diverse product types such as slurries and viscous solutions. Its modular construction allows for seamless integration into existing production lines, and optional pneumatic valves enable semi-automated processing, enhancing operational efficiency. Constructed with 316L stainless steel for product contact parts and featuring sanitary single mechanical shaft seals, the Flashmix is both corrosion-resistant and suitable for CIP (Cleaning-In-Place), ensuring compliance with industry hygiene standards. Additionally, it offers customization options, including various hopper sizes and motor types, to meet specific process requirements and production scales.

Benefits

- Enhances production efficiency by incorporating powders quickly, achieving rates up to 500 lbs/min with minimal manual intervention.

- Guarantees uniformity and quality of mixtures with its agglomerate-free, high shear mixing process.

- Supports a wide range of applications, from high-viscosity to high-temperature environments, broadening production capabilities.

- Reduces operational costs with its low power requirements and integrated self-pumping feature, eliminating the need for additional pumps.

- Simplifies maintenance and cleaning with a CIP-compatible design, minimizing production downtimes.

- Applications

- Vitamins, Water treatment, Cosmetics, Enzymes, Pigments, Food, Chemicals, Fine chemicals, Detergents, Ceramics, Pulp and paper, Biopharmaceuticals, Flavors and fragrances, Solvents, Resins, Baby food, Paints, Pharmaceuticals, Beverages, Powder supplements, Nutraceuticals, Adhesives, Dairy products, Essential oils

- End products

- Cosmetic creams, Paint thinners, Protein powders, Flavored dairy beverages, Processed paper pulp, Ceramic glazes, Chemical reagents, Infant formula, Liquid detergents, Artists' paints, Fragrance compounds, Enzyme solutions, Resin solutions, Industrial adhesives, Fruit juices, Essential oil blends, Water treatment solutions, Vitamin capsules

- Steps before

- Purification, Drying, Grinding, Measuring, Heating, Weighing

- Steps after

- Packing, Sterilization, Quality Control, Coating, Final Mixing

- Input ingredients

- powders, liquids, high viscosity mixes, gums, thickeners

- Output ingredients

- homogeneous product, agglomerate-free mix, dispersed and hydrated powders

- Market info

- Silverson is renowned for manufacturing high-quality industrial mixers, specializing in high-shear mixers for industries such as food, pharmaceuticals, and cosmetics, offering customized solutions and exceptional engineering expertise.

- Powder incorporation rate

- Up to 500 lbs/min

- Liquid flow rate

- Up to 275 gal/min

- Material of construction

- 316L stainless steel

- Motor type

- TEFC motors

- Sealing

- Sanitary single mechanical shaft seal

- Hopper capacity

- 1.4, 3.5 or 10.6 cu ft

- Cleaning method

- Cleaning-In-Place (CIP)

- Self-pumping capability

- Yes

- Size

- Varies based on model

- Batch size

- Up to 10 liters (FMX5)

- Temperature compatibility

- High-temperature operations

- Power requirement

- Low power without additional pumps

- Modular construction

- Yes, for various applications and batch sizes

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Inline Continuous

- Air incorporation control

- Minimized aeration

- CIP/SIP

- Designed for CIP

- Cleaning method

- CIP

- Energy efficiency

- Low power requirement

- Changeover time

- Quick and easy workhead change

- Working mechanism

- High shear mixing

- Integrated steps

- Powder incorporation and hydration

- Ergonomics

- User-friendly design

- Cleanability

- Designed for Cleaning-In-Place (CIP)

- Biological compatibility

- 3-A Certified and EHEDG Certifiable

- Corrosive resistance (e.g. acids)

- 316L Stainless Steel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Agglomerate-free

- Machine Footprint

- Compact design for limited space

- Hopper size

- 1.4 to 10.6 cu ft

- Feed Method

- Powder feed suction hose

- Material of Construction

- 316L stainless steel for contact parts