Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates. Pumping abrasive materials causes ordinary cast-iron bends to wear out over time causing product loss and system downtime.

Convey abrasive materials through bends with low-loss and wear

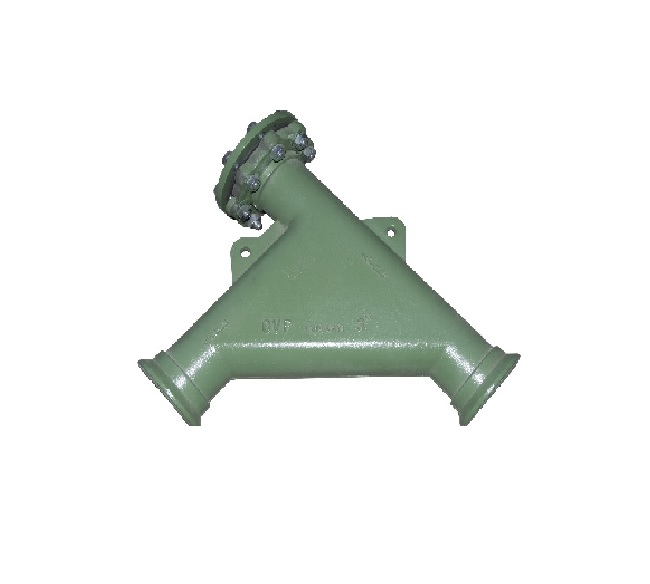

GVF Impianti offers wear-resistant bends for dense phase pneumatic conveyor lines. They are produced in cast iron with Ni-Hard carbonitriding for increased wear resistance. GVF bends are supplied with a revolving split flange which allows them to be rotated as desired. They are supplied with soft gum die casting gaskets and are fitted with an eye-bolt for uplift support.

The CSQ Series bends are squared bends, available with two or three channels in sizes of 2-5 inches. CSQ bends allow the product to form a bed in the bend which helps reduce wear.

The CM series of segmented bends is available in sizes of 2.5 to 4 inches. CM bends are designed to minimize loss of load at the bend. They are composed of three sectors of 30° and can form 30°, 60°, and 90° bends. The three-sector construction allows the replacement of a single element.

Applications include foundry sand handling and conveying of other fine, abrasive, or granular solids including feldspar, fly ash, alumina, carbon black, candies, resins, beans, nuts, and grains.

Benefits

- Reduce replacement downtime with wear-resistant bends

- Easy installation with rotatable flange and eye-bolt

- Increase flow rates by minimizing load loss with segmented bends

- Cut maintenance costs with single segment replacement