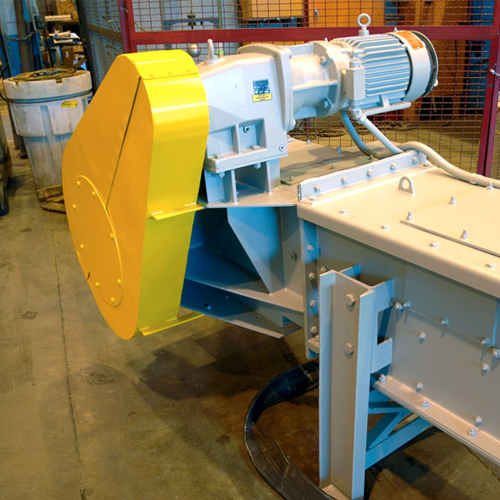

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in demanding environments, ensuring high operational uptime by seamlessly integrating inspection and maintenance features.

Transports and Inspects Bulk Materials Efficiently

The MoveMaster DC Chain Conveyor from Schenck Process is engineered to meet your bulk material handling needs in challenging environments. This conveyor system features a robust mechanical design that utilizes a chain-driven system to transport materials, such as chemicals, fertilizers, cement, and biomass, with precision and efficiency. It’s particularly suited for continuous and fully automated operations, making it ideal for large-scale manufacturing processes. The modular construction allows for rapid inspection and maintenance, integrating component condition monitoring to minimize downtime. Designed with cost-effectiveness in mind, the MoveMaster DC reduces power consumption to 1/10th compared to conventional dense phase conveyors. With entirely enclosed structures, it ensures dust-tight and weatherproof operations, enhancing safety and environmental compliance. Available in various material options to suit different industrial applications, it supports seamless integration into existing transport and yard logistics systems.

Benefits

- Minimizes operational costs with significantly reduced power consumption.

- Enhances operational efficiency through seamless integration into automated processes.

- Decreases maintenance disruptions with easy access for inspection and component monitoring.

- Improves workplace safety with fully enclosed, dust-tight construction.

- Adapts to diverse industrial applications with customizable material options.

- Applications

- Chemicals, Sealants, Coke, Bioplastics, Agrichemicals, Coatings, Coal, Polyolefins, Additives, Adhesives, Steelmaking, Biomass, Paints, Fertilizers, Cement

- End products

- Polyethylene, Epoxy coatings, Steel billets, Herbicide powders, Polypropylene, Ammonium nitrate, Biomass pellets, Silicone sealants, Portland cement, Urea, Coking coal, Pesticide granules, Biodegradable plastics, Acrylic paints, Polyurethane adhesives

- Steps before

- Material intake, Pre-sorting, Pre-conveying, Initial inspection

- Steps after

- Material distribution, Storage, Further conveying, Final inspection

- Input ingredients

- bulk materials, chemicals, compounds, coal, catalysts, fertilizers, biomass, plastics, steel, cement

- Output ingredients

- handled bulk materials, transferred bulk materials, elevated bulk materials

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Chain tension system

- Lifetime alignment visibility

- Component condition monitoring

- Produced for rapid inspection, diagnosis

- Maintenance ease

- Easy replacement of wear components

- Power Running Costs

- Significantly lower than most other forms of equipment

- Construction

- Heavy duty rigid construction in simple modules

- Environmental Safety

- Totally enclosed machines and transfer points

- Control system

- Manual to fully automatic control

- Chain type

- High strength chain

- Maintenance interval

- Infrequent

- Flexibility

- Operation in demanding environments

- Automation Level

- Manual / PLC-controlled

- Preventative Maintenance

- Simple / Minimal Downtime

- Inspection Ease

- Easy / Rapid

- Changeover Time

- Quick / Minimal disruption

- Energy Efficiency

- Low Power Running Costs

- Environmentally Acceptable

- Enclosed / Dust-tight construction

- Reliability

- High / Proven Performance

- Durability

- Heavy duty / Rigid construction

- Customization Options

- Modular / Configurable

- Maintenance Requirements

- Infrequent / Easy

- Machine footprint

- Compact

- Chain tension system

- Automatic

- Construction

- Heavy duty rigid

- Design inspection

- Easy Access

- Component condition monitoring

- Yes

- Lifetime alignment visibility

- Yes

- Discharge method

- Enclosed transfer points

- Control System Type

- Manual / PLC / BASIC control systems

- Inspection Ease

- Rapid inspection, diagnosis

- Maintenance Access

- Easy replacement of wear components

- Chain Tension System

- Included

- Condition Monitoring

- Component condition monitoring

- Alignment Visibility

- Lifetime alignment visibility

- Environment Suitability

- Dust-tight and weatherproof construction

- Automation Level

- Manual to fully automatic

- System Integration

- Single or multiple machine systems