Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide legal-for-trade, high-speed weighing of solids and liquids, optimizing your logistics by reducing shunting and enhancing data accuracy during transit.

Weighs and Monitors Rail Cars Dynamically

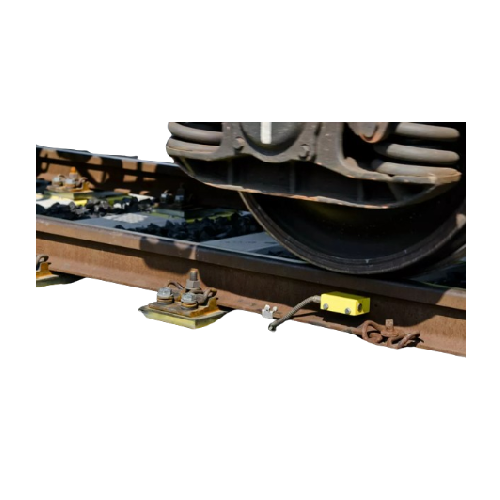

Schenck Process’s MULTIRAIL LegalWeight system is a dynamic train scale engineered for precise legal-for-trade rail car weighing. This equipment stands out by providing high-accuracy measurements during train transit, crucial for industries like chemicals, steelmaking, and logistics. The system effectively monitors wheel, axle, and wagon loads, optimizing axle load distribution and center of gravity precision. Suitable for both solids and liquids, it enables continuous weighing with integrated database systems for intelligent data analysis and remote diagnostics. Featuring a robust construction with stainless steel weighbeams and the option for an integrated control scale, it ensures durability and compliance with OIML R 106 standards. The modular design allows for fast installation with minimal rail disruption. MULTIRAIL LegalWeight maximizes operational efficiency up to 15 km/h, reducing shunting needs and supporting high-speed logistics and rail industry operations.

Benefits

- Enhances operational efficiency with high-precision dynamic weighing, reducing shunting and handling costs.

- Legal-for-trade accuracy ensures reliable invoicing, minimizing disputes over weight discrepancies.

- Integrated remote diagnostics lower maintenance costs through proactive monitoring.

- Modular setup allows quick installation, minimizing track downtime and disruption.

- Robust stainless steel construction offers durability, suitable for challenging industrial and environmental conditions.

- Applications

- Sealants, Catalysts, Rail vehicles, Liquids, Chemicals, Cement, Coke, Agrichemicals, Coal, Solids, Biomass, Batteries, Additives, Fertilizers, Logistics, Colorants, Paint, Coatings, Adhesives, Steelmaking

- End products

- Polypropylene compounds, Rail tank cars, Lithium-ion batteries, Npk fertilizers, Polystyrene films, Additive masterbatch, Crude oil, Acrylic paints, Epoxy coatings, Biomass pellets, Hydraulic cement, Steel plates, Polyester colorants, Steel rebars, Urea, Bulk chemicals, Liquid gases, Hopper wagons, Coal briquettes, Ethanol, Silicone sealants

- Steps before

- Loading, Transport to weighing station, Arrangement of rail cars

- Steps after

- Data analysis, Invoicing, Offloading, Logistics planning, Maintenance of weighing equipment

- Input ingredients

- solids, liquids, rail cars, trains

- Output ingredients

- precise weight measurements, dynamic weighing data, legal-for-trade weight results

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Accuracy

- Legal-for-trade, class 0.5 and 0.2

- Weighing Speed

- Up to 15 km/h

- Temperature Range

- –10°C to +40°C

- Installation

- Fast, gap-free by exchanging ties

- Material

- Robust concrete ties and stainless steel weighbeam IP 67

- Integration

- Integrated static reference scale

- Automation

- Intelligent measurement data analysis and online remote diagnosis

- Load Monitoring

- Monitoring wheel, axle, and wagon load

- Automation level

- PLC / SCADA

- Legal-for-trade compliance

- OIMLR 106, class 0.5 and 0.2

- Temperature range

- –10°C to +40°C

- Dynamic vs. Static Operation

- Dynamic

- Integrated control scale

- Optional

- Installation

- Fast, gap-free installation

- Monitoring capabilities

- Remote diagnosis, online system monitoring

- Wheel,axle,and wagon load monitoring

- Integrated

- Center of gravity monitoring

- Enabled

- Speed for weighing

- Up to 15 km/h

- Shunting

- Reduced requirement

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Cleanability

- Easy to clean surfaces

- Density/particle size

- 0.5–2.5 g/cm³

- Material Type

- Solids and liquids

- OIML Certification

- R 106, class 0.5 and 0.2

- Temperature Range Certification

- –10°C to +40°C

- Machine footprint

- Compact design

- Installation type

- Modular design for quick installation

- Construction material

- Stainless steel, Robust concrete ties

- Control cabinet type

- On-site electronics DISOBOX Plus MR

- Discharge method

- Dynamic train scales for legal-for-trade weighing

- Environment operational temperature range

- -10°C to +40°C

- Load capacity

- High-precision rail car weighing

- Speed capability

- Up to 15 km/h for legal-for-trade weighing

- Data integration

- Integrated with standard software

- Monitoring type

- Wheel, axle, and wagon load monitoring