Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with continuous processing, ensuring uniform product quality and efficiency while reducing operational footprint. Ideal for manufacturers looking to streamline production without sacrificing end-product consistency.

Mixes and Homogenizes Liquid Formulations

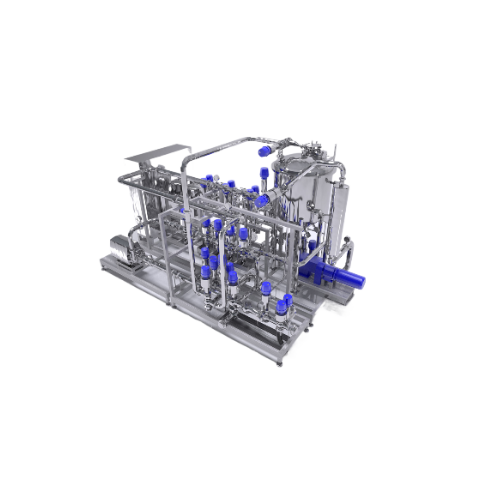

The Continuous Mixer Type LVA Skid from GEA is designed to streamline and enhance the production of high-viscosity liquid formulations in the home and personal care industries. Utilizing a highly configurable continuous mixing process, this equipment ensures precise homogenization and temperature control, essential for producing consistent and high-quality products like shampoos, liquid soaps, and detergents. Capable of high-speed operations, it offers seamless integration into existing production lines with its PLC-controlled system, allowing for real-time monitoring and adjustments. Its energy-efficient design, boasting a variable-speed motor, reduces operational costs, while the option for stainless steel construction ensures durability and compatibility with various chemical processes. The system includes an integrated CIP feature for efficient cleaning, reducing downtime and maintaining product quality. Additionally, GEA offers extensive customization and engineering support to tailor the equipment to specific production needs, ensuring compliance with industry regulations and certifications.

Benefits

- Enhances product consistency and quality with precise homogenization.

- Minimizes operational costs through energy-efficient variable-speed motor.

- Integrates seamlessly into existing processes with PLC-controlled operation.

- Reduces cleaning time and contamination risk with CIP system.

- Customizable to meet specific production requirements and ensure regulatory compliance.

- Applications

- Chemicals, Liquid formulations, Personal care products, Detergents, Home care products

- End products

- Hair conditioner, Household disinfectant, Liquid laundry detergent, Dishwashing liquid, Liquid hand soap, Adhesives, Shampoo, Body wash, Fabric softener, Surface cleaner, Paints

- Steps before

- Weighing, Loading, Pre-mixing

- Steps after

- Discharging, Cleaning, Packaging

- Input ingredients

- raw materials, powders, liquids, solids, flakes, high viscosity materials, low viscosity materials

- Output ingredients

- homogeneous mixture, blended product, mixed product, structured liquids, dispersions

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Mixing Method

- Batch / Continuous

- Shear Mixing

- High / Low

- Mixing Cycle Time

- Seconds to Hours

- Process Integration

- Inline / Standalone

- Homogenization Capability

- Yes / No

- Heating,Cooling Range

- Yes / No

- Vacuum Mixing

- Yes / No

- Automation Level

- Manual / PLC / SCADA

- Materials Compatibility

- Liquids / Solids / Flakes

- Mixing Vessel Size

- Varies

- Flow Meter Accuracy

- High Precision

- DICON™ System

- Available

- Batch Size

- Small to Large Volume

- Batch vs continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Process Intensification

- More product with less equipment

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Customizable based on plant requirements

- Tank shape and size

- Varies, tailored to specific application

- Feed method

- Manual/Automatic loading

- Discharge method

- Automatic/manual discharge

- Compact design

- Yes, designed for limited space applications

- Control panel type

- PLC/Manual interface

- Control panel type

- PLC / HMI

- Automation level

- Manual / PLC / SCADA

- Integration possibilities

- Third-party systems

- Discharge method

- Manual / Automated