Drum mixer for dispersions & agitations

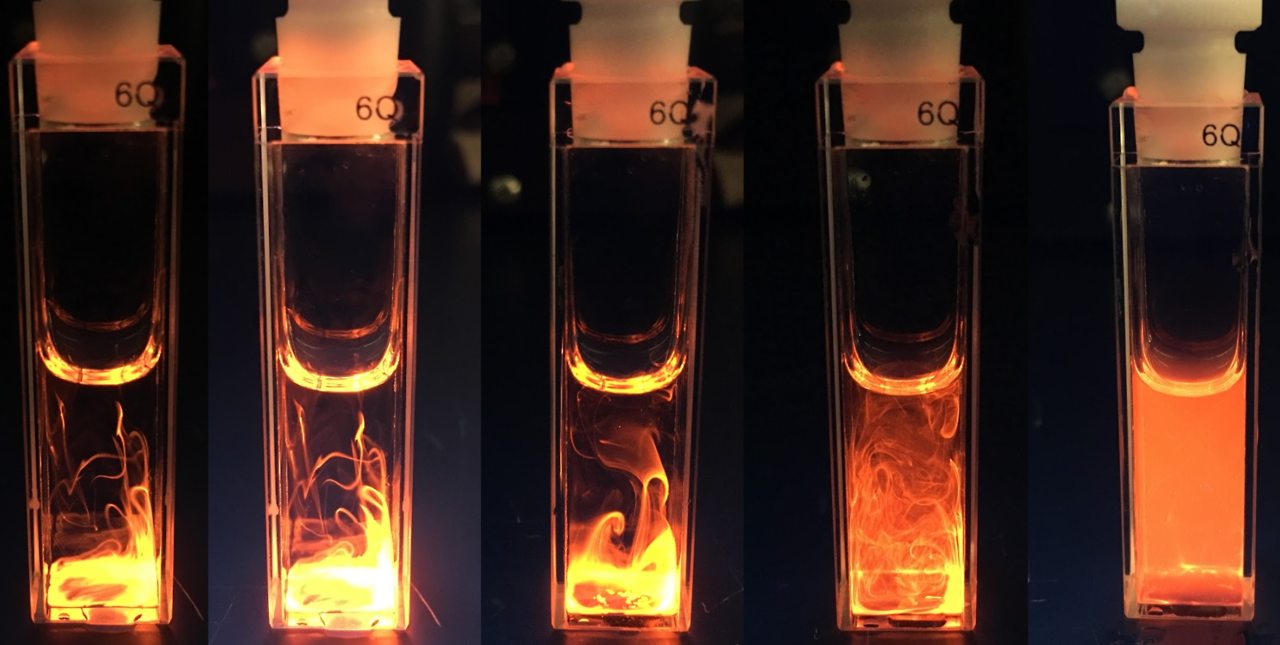

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mixer designed for precise batch processing, optimizing your production time and ensuring consistent results across a wide range of liquid and slurry-based products.

Processes Dispersions and Agitations in Liquid Formulations

The Drum Mixer from Hockmeyer Equipment Corporation offers explosion-proof mixing for dispersions and agitations in industries such as chemicals, paints, and cosmetics. Engineered for standard 55-gallon drums, it handles batches starting at 3 gallons, with an 8-inch diameter blade driven by a 15-horsepower motor. This mixer excels in versatility, accommodating different blade styles to optimize dispersion. It features a variable frequency inverter for precise control, and can be mounted on a rail system for service across multiple drums. Safety features include start-stop controls, a height limit switch, and manual raising and lowering of the unit. Ideal for manual, high-speed operations, it supports a range of liquid and slurry product types, from industrial inks to cosmetic creams. Options for floor mounting increase its adaptability in diverse production environments.

Benefits

- Enhances production flexibility by processing batches from 3 to 55 gallons.

- Ensures safety in hazardous environments with explosion-proof motor design.

- Optimizes mixing speed and consistency with variable frequency inverter control.

- Facilitates quick adaptation across multiple production lines with optional rail-mounted configuration.

- Increases operational safety with integrated height limit switch and secure can lock.

- Applications

- Dispersions, Agitations, Liquid formulations, Coating materials

- End products

- Cosmetic creams, Sealants, Chemical suspensions, Paint and coatings, Flavor emulsions, Adhesives, Lotions, Industrial inks

- Steps before

- Material Preparation, Pre-mixing, Sizing, Loading

- Steps after

- Packing, Quality Control, Storage, Labeling

- Input ingredients

- Output ingredients

- Market info

- Hockmeyer Equipment is known for manufacturing high-quality industrial mixing and dispersion equipment. They specialize in ETO solutions for industries like paints, inks, and chemicals, renowned for innovation, reliability, and superior engineering.

- Motor Power

- 15 Horsepower

- Motor Type

- Explosion Proof

- Overall Height

- 138″

- Stroke

- 36″

- Width

- 22″

- Blade Diameter

- 8″ ‘D’ Style

- Variable Frequency Inverter

- Yes

- Height Limit Switch

- Yes

- Can Lock

- Yes

- Batch Size Range

- 3 gallons to 55-gallon drum

- Batch vs. continuous operation

- Batch

- Automation level

- Variable Frequency Inverter

- Cleaning method

- Manual

- Energy efficiency

- Explosion-proof motor

- Cleaning method

- Height Limit Switch and Can Lock Safety

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 138″ Overall Height, 36″ Stroke, 22″ Width

- Blade Diameter

- 8″ Diameter ‘D’ Style Blade

- Mounting Type

- Wall Mounting / Free Standing

- Support Legs Option

- Yes

- Batches Capacity

- 3 to 55 Gallons

- Batch Container Compatibility

- Standard 55-gallon drum, 5-gallon pail

- Column Mounting,Counterbalance

- Yes

- Height Limit Switch

- Yes

- Can Lock Feature

- Yes

- Legs for Floor Mounting

- Available

- Compact footprint

- Wall mounting or free standing

- Control panel type

- Start and Stop Push Buttons and a Speed Potentiometer

- Custom blade style

- Any style of blade for optimal dispersion

- Mounting Options

- Legs available for Floor Mounting

- Processing Capacity

- 3 gallons in a 5-gallon pail to 55-gallon drum

- Transportation Method

- Mounted to a rail system for servicing multiple drums