Making Lotions

Find innovative production technology for making lotions and connect directly with world-leading specialists

After shaving, anti-aging, with organic ingredients, for the feet... Lotions are many. They compose the skincare world, which has been growing in recent years. More consumers look for the benefits of products that promise to enhance well-being and self-care. Whether you want to help prevent wrinkles, provide vitamins or just hydrate your consumers’ skin, get your formula and select lotion making equipment to get started.

Tell us about your production challenge

Water and oil proportions in lotions vs creams

Water is the main ingredient in lotions, and it is what differentiates this product from creams, which usually contain a 50-50 ratio of water and oil. The massive presence of water is what makes it easier for the skin to absorb the product. This means that lotions go better with oily skin, and creams, with dry skin. Either way, water and oil don’t mix easily, and conventional agitators may not provide the homogenized result consumers look for.

How to properly homogenize ingredients and keep their properties

Apart from the water and oily phases, active ingredients are the key to delivering the benefits consumers seek in lotions. These are components like vitamin C, hyaluronic acid, retinol or salicylic acid, for instance, which are present for the specific product’s purpose. Mixing is an essential step to create a stable emulsion and allow all ingredients to accommodate properly. Homogenizers and other types of lotion making equipment help reduce particle sizes and create the right consistency for lotions. Using emulsifier also help, as they bind to both water and oil due to their polar and nonpolar characteristics.

Manufacturing vegan (indeed) lotions

A big debate in the skincare industry is animal testing, as more consumers look for products that are cruelty-free. While some brands claim to be that, they are sometimes part of companies that need to test products on animals as some countries still require that, for some products. One example is China when it comes to “special cosmetics” like sunscreen or hair dye, and infant and children products. Lotions are out of this scope, considered “general cosmetics” and don’t need to go through animal testing in the country.

Manufacturers aiming to assure their consumers that their products are indeed animal-friendly should seek the Leaping Bunny Logo. The Leaping Bunny Program is an international standard established by the Coalition for Consumer Information on Cosmetics (CCIC), which defines general parameters on what is (definitely) cruelty-free.

Processing steps involved in lotions making

Which lotions technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

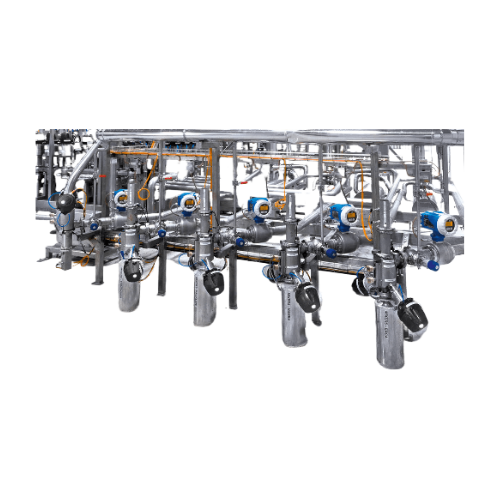

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Semiautomatic labelling solution for cylindrical bottles

Effortlessly apply precise labels to various cylindrical and squ...

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

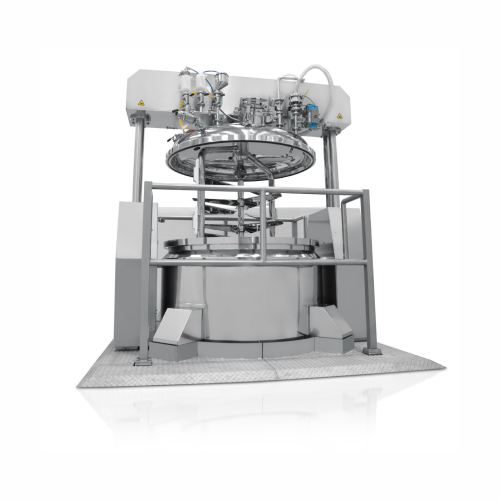

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

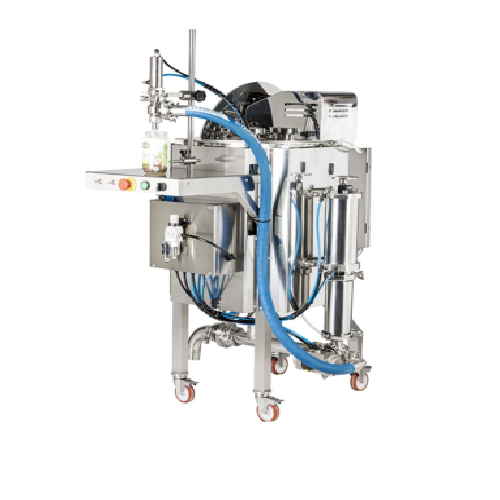

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Versatile industrial melter for raw ingredients

Enhance your formulation capabilities with a flexible melter designed for ...

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Vacuum turboemulsifier for small-scale production

Optimize your product development with versatile vacuum turboemulsifier...

Melting tank for cosmetic production

Achieve precise and consistent melting and dosing of cosmetic liquids, from face cream...

Lipstick packaging fit tester

Ensure precise packaging fit for lipsticks, improving product quality and decreasing return ra...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

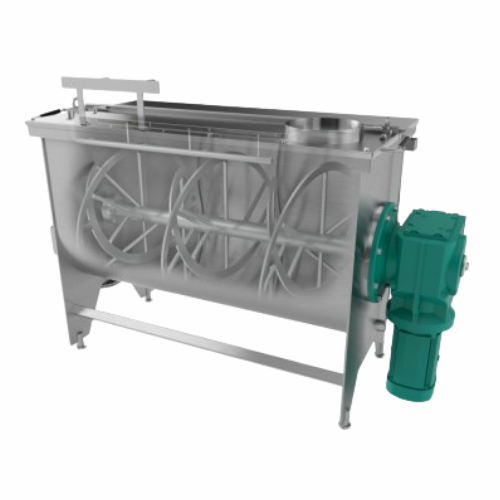

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

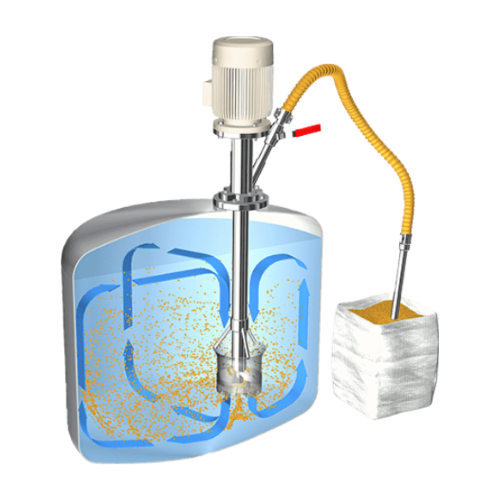

Hydroalcoholic gel mixing system

Ensure seamless production of hydroalcoholic gels with an advanced mixing system designed f...

Hydrocolloid powder dispersion unit

Achieve seamless dispersion of hydrocolloid powders in liquids, eliminating common issu...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

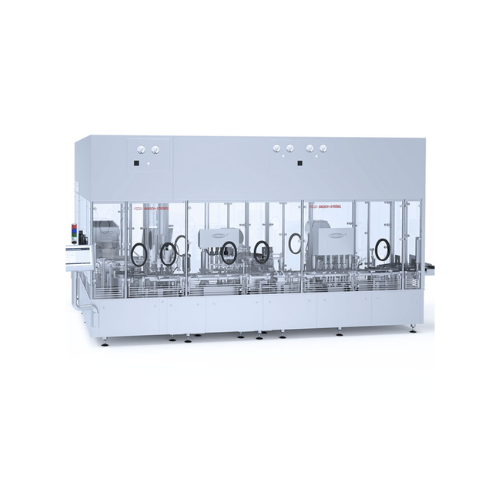

Rotary filling and closing system for pharmaceutical bottles

Optimize your large-batch liquid production with a high-spe...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

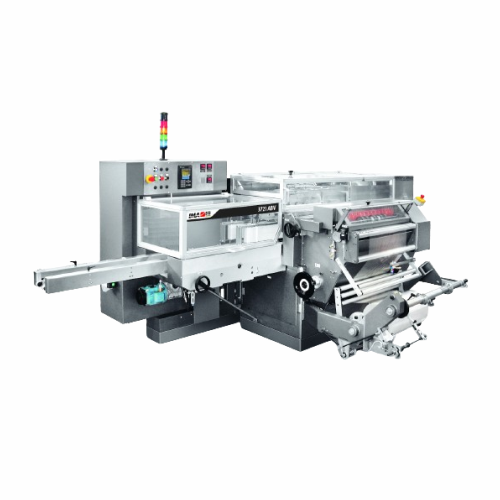

Wet wipes converting line

Efficiently convert a variety of wet wipes with flexible settings and minimal machine downtime, en...

Complete over wrapping for parallelepiped products

Optimize your packaging line with high-speed over wrapping for precisi...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

High-performance cartoning system for pharmaceutical products

Optimize your packaging line with a flexible cartoning sol...

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Industrial steam washer for pharmaceutical and food industry

For production lines requiring efficient and eco-friendly c...

Self-adhesive labeling system for unstable cylindrical containers

Ensure precise labeling of unstable cylindrical conta...

Self-adhesive labeling for multi-format containers

Ensure precision on diverse container shapes with a high-speed, self-a...

Linear labeller for self-adhesive labels in pharma

Ensure precise labelling with integrated inspections and traceability ...

Rotary hot melt labeller for pre-cut labels

Achieve precise high-speed labelling of diverse containers with enhanced adhes...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Compact elevator tipper for craft businesses

Optimize your production line with a versatile elevator tipper that ensures s...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Vertical cartoning solution for fragrance and skincare products

Effortlessly carton even the most delicate cosmetics wit...

Tube filling solution for health and beauty applications

Achieve consistent quality and efficiency in tube filling operat...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

High-pressure reactor for cosmetic and pharmaceutical production

Ensure precise formulation and enhanced product stabili...

Cleaning in place systems for bioreactors

Ensure seamless sanitization with a mobile cleaning system designed to maintain ...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

Undervacuum homogenizer for cosmetic and pharmaceutical creams

Optimizing the production of creams and lotions, this und...

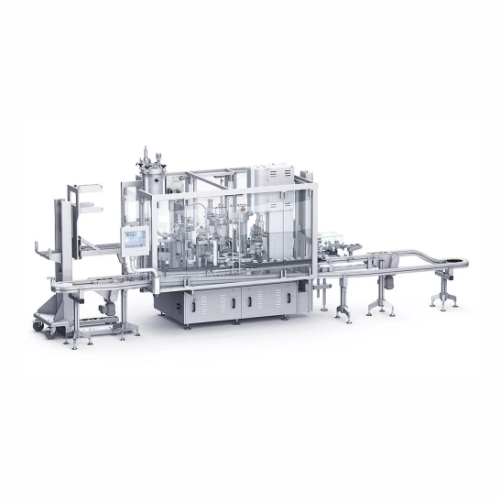

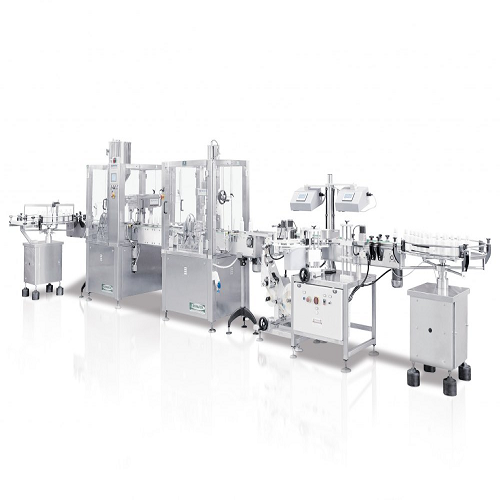

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

Manual tube sealer for plastic and laminated tubes

Secure precise and reliable seals on plastic and laminated tubes with ...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Cip clean-in-place system for undervacuum homogenizers

Ensure seamless sanitation for your undervacuum homogenizers with ...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Industrial water chiller for homogenizers and filling machines

Optimize your production line with customizable water chi...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Automatic bottles and jars filling and capping line

Streamline your liquid product packaging with this high-speed solutio...

Label inspection for vertical products

Ensure label quality and accuracy with advanced inspection technology designed for p...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

Industrial checkweighers for medium-large products

Manage large and heavy packagings with precision and efficiency, ensur...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Semi automatic Pet bottle blow molding solution

Streamline your production with a semi-automatic solution designed for eff...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Single seat valve for hygienic applications

Ensure optimal hygiene and safety with a versatile pneumatic valve designed to...

Rotary jet head for hygienic tank cleaning

Ensure efficient, hygienic cleaning with a rotary jet head designed to optimize...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Pneumatic cap press for bottles and jars

Streamline your packaging process with a pneumatic solution designed for precision...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Front and back labelling for small production lines

Streamline your labelling process with precise front and back applica...

Full body sleeving systems for packaging applications

Achieve seamless, high-speed labeling precision for diverse contain...

Ultrasonic tube sealer for plastic tubes

Seal plastic tubes with precision and speed using our ultrasonic technology, ensur...

Bottle unscrambler for plastic containers

Efficiently organize and streamline your production line by ensuring plastic con...

Form, fill, and seal system for single-use pouches

Achieve precise portion control and secure sealing with an integrated ...

Automatic pressure sensitive labeling system

Enhance your production line’s efficiency with a versatile labeling sys...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Hygienic pump for beverage and pharmaceutical industries

Engineered to meet stringent hygiene demands, this versatile pum...

Rotary lobe pump for viscous media

Ensure precise handling and gentle transfer of viscous liquids with advanced rotary lobe...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Laboratory homogenizer for scaling nisox-valve benefits

Achieve reliable scaling from lab to production with this precise...

Industrial depalletizer for high-speed operations

Optimize your production line efficiency with a high-speed depalletizin...

High-efficiency ammonia chiller package for industrial applications

Optimize your cooling and refrigeration processes w...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Volumetric bottle filler for high proof spirits

Ensure precise and consistent bottle filling for high-proof spirits with t...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Explosion-proof production vacuum disperser for viscous products

Achieve precise and reliable dispersion of high-viscosi...

Industrial mixer for product-critical processes

When dealing with high-hygiene requirements and complex mixing tasks acros...

Gmp contact part washers for pharmaceutical industry

Ensure product integrity and hygiene with specialized washing system...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Automatic tube filling for multi-color products

Achieve precision in multi-color product packaging with seamless co-extrus...

Automatic case packer for cartons and bundles

Optimize your packaging process by efficiently inserting single cartons and ...

Small batch tube filling system for metal and plastic tubes

Optimize your small-batch production with precise tube filli...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

Feed hopper for volumetric feeders

Optimize product consistency while handling a variety of viscosities with this feed hopp...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Manual filler and capper for spouted pouches

Easily manage filling and capping for flexible pouches with precise volumetri...

Semi-automatic capping solution for small to medium operations

Streamline and personalize your capping processes with ve...

Shear pumps for continuous on-line dispersion

Effortlessly achieve consistent shearing and mixing with versatile shear pum...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Scraped surface heat exchanger for high-viscosity products

Designed for handling high-viscosity products, this system en...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Injection stretch-blow molding system for Pet containers

For manufacturers aiming to produce versatile, high-quality PET ...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

External washing and drying system for sealed vials

Ensure contamination-free packaging of liquid vials with this precise...

Automatic labelling system for pharmaceutical vials

Ensure precise and efficient packaging for cylindrical containers wit...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

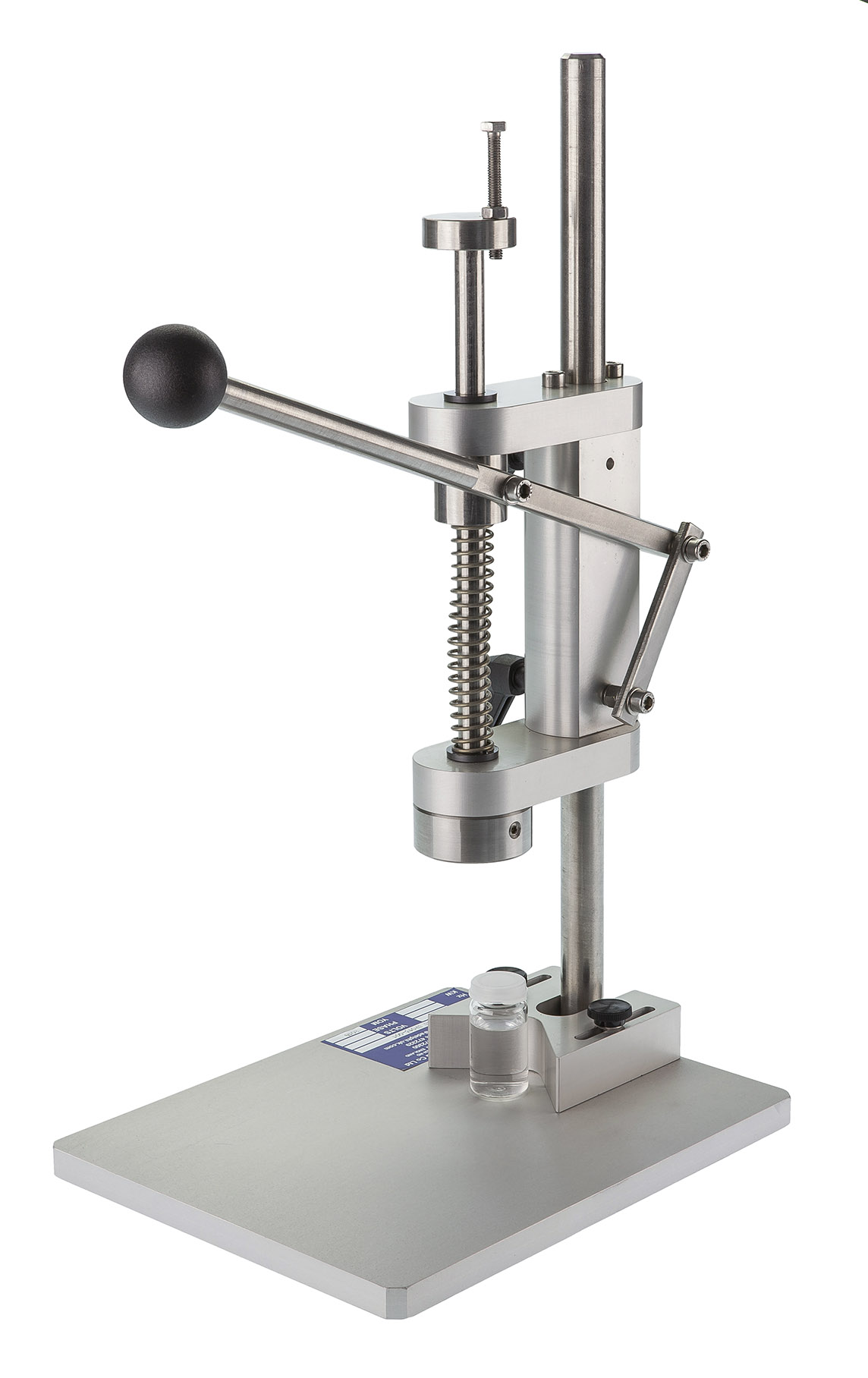

R&D bottle cap press

When you are a small-scale producer of liquids contained in bottles with press-on lids and caps you need...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

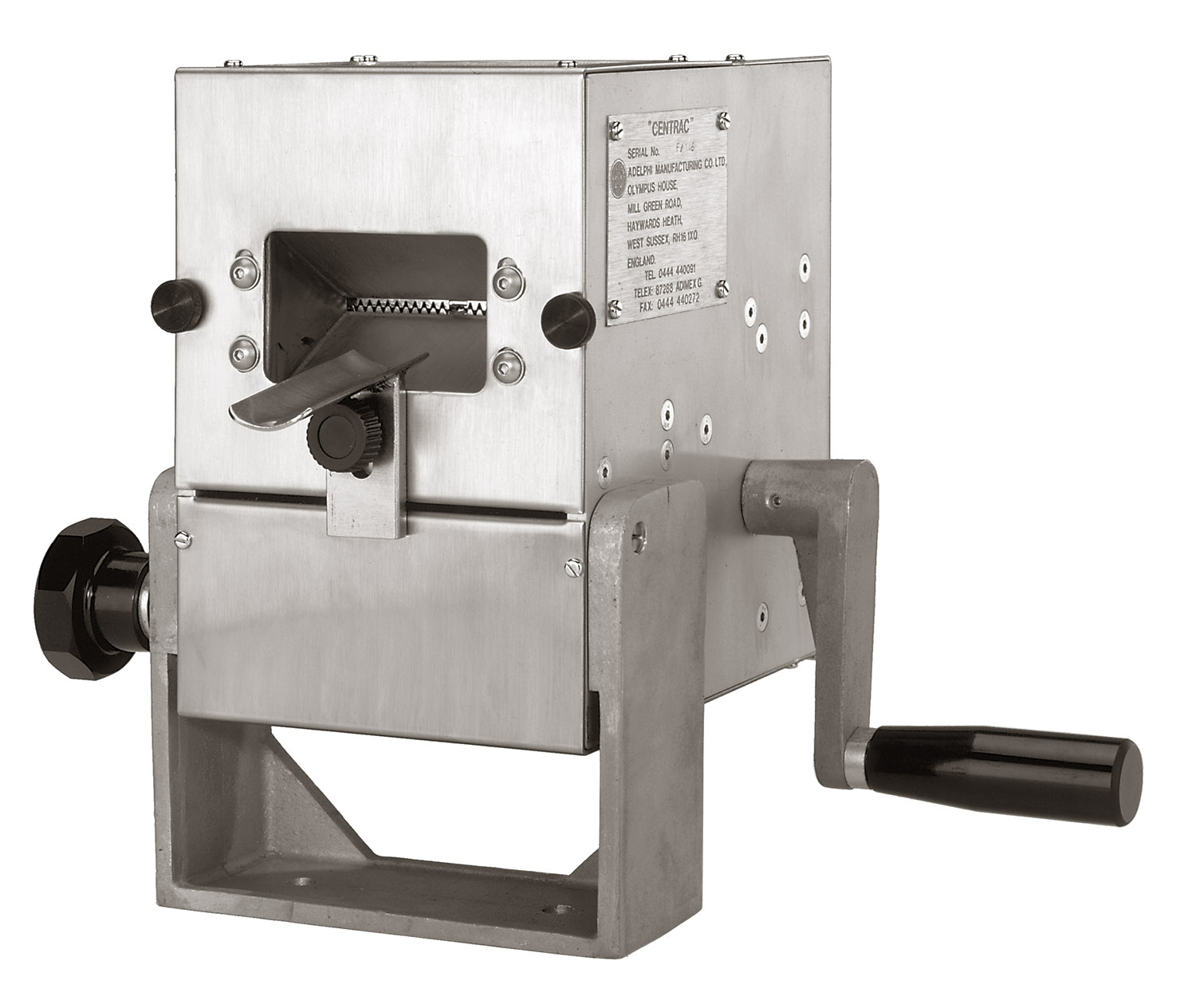

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

Homogenizer for creams

Homogenization (or pharmaceutical micronization) is the process of reducing particle sizes, and is a v...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

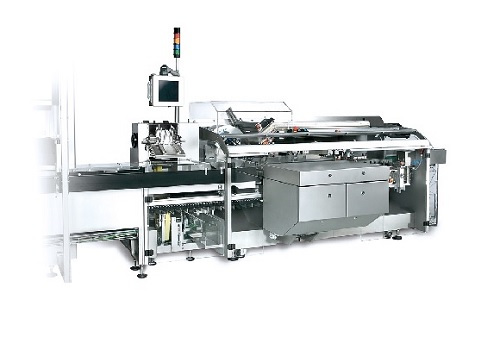

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

A two-component filling application tube filler

A wide variety of pharmaceutical, cosmetic and food products require tube-...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Laboratory size auto-steam shrink system

When managing sleeving projects, fast prototyping and testing can gain massive com...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...