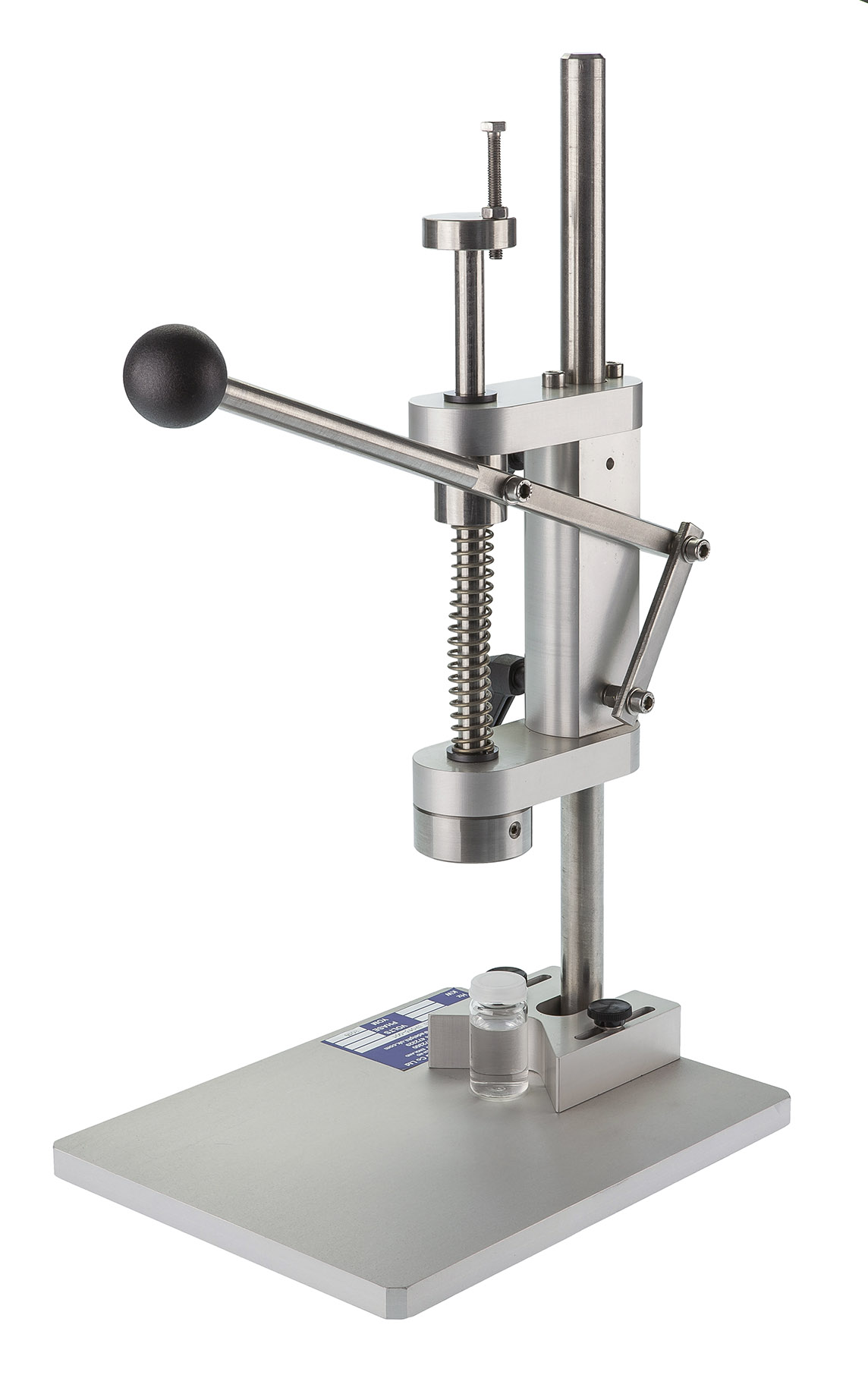

R&D bottle cap press

When you are a small-scale producer of liquids contained in bottles with press-on lids and caps you need capping machines to ensure constant cap pressure and a leak-free output. Adapting to different bottles and caps can also become an advantage.

Pressing caps and press-on lids through a pneumatic operation

The Pneumatic Cap Press from Adelphi is a pneumatically operated capping system for plastic and glass bottles with diameters ranging from 22 to 85mm. The system features an adjustable height of up to 240mm with depth adjustments to accommodate a wide range of bottle shapes and sizes. The press pads are custom-made to suit the shaped caps used by the customer. The unit is made from hygienic anodized aluminum and stainless steel for durability and long service life. The system produces an approximate output of 6 to 10 bottles per minute.

Benefits

- Adjustable height (up to 240mm) with a bottle diameter range of 22mm to 85mm

- High output (up to 600 pieces per hour)

- Intuitive and simple to use

- Customized press pads for different caps