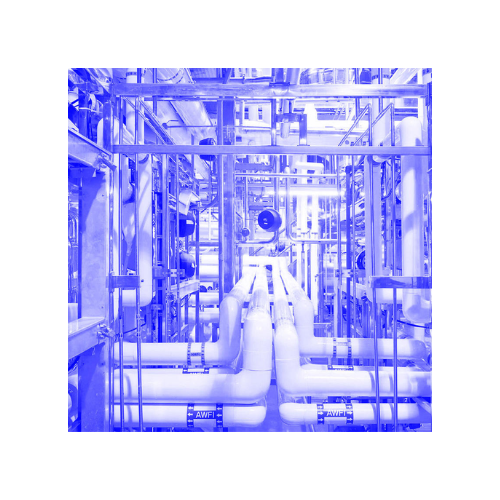

Cleaning in place systems for bioreactors

Ensure seamless sanitization with a mobile cleaning system designed to maintain product purity in bioreactor operations, reducing downtime and enhancing operational efficiency.

Automates and Optimizes Cleaning Processes

The CIP-Mobile Cleaning System from Bioengineering AG is engineered to streamline and enhance sanitation processes across various industries, including biopharmaceuticals, food, and cosmetics. This system excels in its ability to automatically clean complex equipment like fermentors and bioreactors through a meticulously controlled sequence involving pre-rinsing, alkaline cleaning, and final rinsing. Designed with flexibility in mind, it includes up to 28 programmable cleaning steps and is equipped with dual 200-liter tanks, a circulation pump, heat exchangers, and robust parameters control such as temperature and flow rates. Ideal for tackling challenges in operations ranging from pilot to large-scale production, this solution ensures surfaces in contact with products remain free of contaminants to avert cross-contamination. Constructed with high-grade materials, it supports recycling of cleaning solutions where applicable, promoting both economic and ecological benefits. The CIP-Mobile is compatible with industrial standards, featuring seamless integration with existing production lines through its PLC-controlled system, offering reliable documentation and control adjustments to meet stringent hygiene requirements.

Benefits

- Prevents cross-contamination with thorough and programmable cleaning cycles.

- Enhances operational efficiency with flexible deployment, accommodating both mobile and fixed installations.

- Reduces downtime through automated, PLC-controlled sanitation processes.

- Supports sustainability initiatives by allowing recycling of cleaning solutions.

- Meets stringent hygiene standards with comprehensive documentation and process adaptability.

- Applications

- Food, Beverages, Chemicals, Homeopathy, Metallurgy, Nutritional products, Alternative medicine, Cosmetics, Biopharmaceuticals, Petrochemicals, Mining, Pharmaceuticals

- End products

- Herbal tinctures, Vaccines, Steel additives, Probiotic drinks, Solvents, Protein supplements, Tablets, Lotions, Gold extraction reagents, Beer, Plasticizers

- Steps before

- Media/Buffer Preparation, Component Dosing, Solution Mixing

- Steps after

- Final Rinsing, Blowing Out, Quality Assurance/Quality Control

- Input ingredients

- NaOH, acids, alkaline solution, cleaning agents, water for injection (WFI), piping, chemical substances, mixing tanks, dosage vessels

- Output ingredients

- clean surfaces, contaminant-free surfaces, recycled CIP solutions, recirculated rinsing liquids

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Cleaning steps

- Up to 28 programmable steps

- Tank Capacity

- Two 200-liter tanks

- Circulation pump

- Yes

- Heat Exchangers

- For steam

- Measurement and control parameters

- Temperature, flow rates, conductivity

- Automation

- PLC-controlled

- Recyclability

- Recyclability of the cleaning solutions

- CIP loops

- Precisely defined for all transitional zones

- Cleaning agents

- Alkaline solution (2-3% NaOH)

- Cleaning steps

- Pre-rinsing, cleaning, rinsing, final rinsing, blowing out

- Final rinsing

- WFI (Water for Injection)

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline

- Integrated steps

- Pre-rinsing, Alkaline Cleaning, Rinsing, Final Rinsing, Blowing Out

- Energy efficiency

- Optimized for economic and ecological processes

- Working mechanism

- Multiple tanks, circulation pumps, heat exchangers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Programmable Logic Controller (PLC)

- Integration possibilities

- BioSCADA integration

- Tank size

- 200 liters

- Heat exchangers type

- Steam