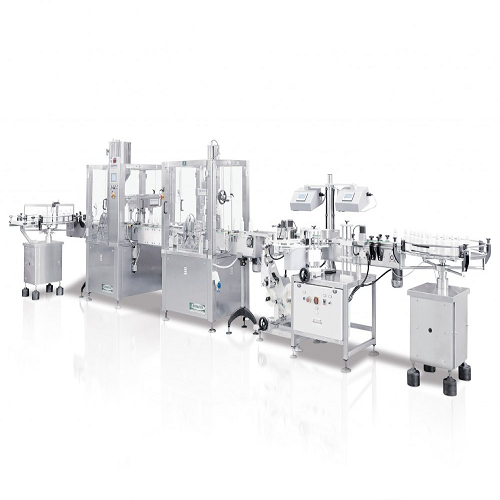

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrating seamless filling, capping, and labeling—ideal for enhancing efficiency and precision in continuous operations.

Fills, Caps, and Labels Liquid Products

The Axofill Axocap, crafted by Axomatic, is a versatile bottle filling and capping machine designed for precision and efficiency in liquid product processing. This machine excels in integrating with production lines, featuring a rotating table for stable container loading and an outlet belt for straightforward connection to capping or labeling units. The dosing system offers adjustable strokes between 30 and 200 mm, adeptly managing container diameters from 30 mm to 110 mm.

Engineered with AISI 304L stainless steel, it guarantees durability and corrosion resistance, vital for pharmaceutical and cosmetics production environments. Capable of processing up to 50 pieces per minute, the Axofill Axocap suits continuous, high-speed operations. For improved usability, its electrical installation is enclosed within the machine’s perimeter, complementing the frontal control panel for effortless operator access. Additionally, the product loading hopper and anti-drop system enhance performance stability, aligning with industry compliance standards and streamlining maintenance protocols.

Benefits

- Maximizes production efficiency with high-speed, continuous operation up to 50 pcs/min.

- Ensures precise dosing with adjustable nozzles, reducing product waste.

- Enhances durability with corrosion-resistant AISI 304L construction, suitable for rigorous environments.

- Facilitates seamless integration with existing lines, minimizing disruption and setup time.

- Improves operator safety and accessibility with an intuitively positioned control panel.

- Applications

- Personal care products, Liquid formulations, Nutraceuticals, Cosmetics, Pharmaceuticals

- End products

- Shampoos, Herbal extracts, Conditioners, Ointments, Liquid supplements, Essential oil blends, Lotions, Syrups, Face serums, Creams

- Steps before

- Container Selection, Container Preparation, Loading Containers onto Rotating Table

- Steps after

- Capping, Labeling, Packaging, Collection of Filled Containers

- Input ingredients

- Output ingredients

- Market info

- Axomatic, part of the Marchesini Group, is known for manufacturing high-quality automated machinery for packaging, particularly in the cosmetic, pharmaceutical, and food industries, with a reputation for innovation and customization in engineered-to-order equipment.

- Filling speed

- 20–50 pcs/min

- Container diameter

- 30mm–110mm

- Container height

- 50mm–250mm

- Dosing stroke

- 30mm–200mm

- Material of machine frame

- AISI 304L

- Filling system configuration

- 2 or 4 filling systems

- Dosing nozzle adjustability

- Adjustable stroke between 30 and 200mm

- Container handling

- Stable container loading on rotating table

- Speed

- 20 to 50 pcs/min

- Automation level

- Frontal control panel with easy access

- Product transfer

- Outlet belt for connecting capping or labeling machine

- Anti-drop capability

- Anti-drop system

- Corrosive resistance (e.g. acids)

- AISI 304L Steel

- Cleanability

- Hygienic design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Low to Medium

- Filling Speed

- 20 - 50 pcs/min

- Machine frame material

- AISI 304L

- Container diameter range

- 30mm - 110mm

- Container height range

- 50mm - 250mm

- Product loading hopper

- Available

- Control panel location

- Frontal

- Rotating table

- For container loading

- Outlet belt connection

- Capping/Labeling machine compatible

- Discharge method

- Rotating collection table

- Rotating table to load containers

- Stable containers

- Filling systems

- 2 or 4 filling systems

- Outlet belt connectivity

- Capping or labeling machine

- Dosing group nozzles

- 2 or 4 diving nozzles

- Adjustable stroke

- 30 - 200 mm

- Material

- AISI 304L

- Anti-drop system

- Included

- Product loading hopper

- Customizable