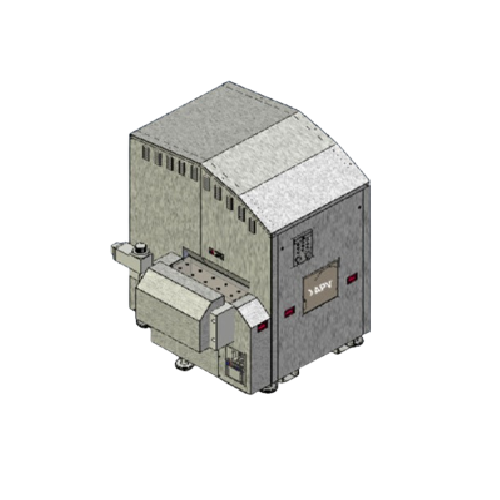

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure homogenizer, designed to enhance texture and stability in liquid-based products while ensuring consistent quality and efficiency in various processes.

Enhances Emulsification and Particle Size Reduction

The APV Gaulin 132CPR Series homogenizer by APV Gaulin is engineered for high-pressure homogenization, ideal for optimizing emulsification and particle size reduction in diverse industries such as food, beverage, and pharmaceuticals. This machine features a 5-plunger design with application-specific homogenizing valve assemblies, ensuring precise control over your production process. Its hydraulic actuation supports continuous, high-pressure operations, making it effective for producing consistent end-products, including dairy, plant-based milks, and pharmaceutical emulsions.

Capable of integrating seamlessly into complex production lines, the Gaulin 132CPR Series offers automation with configurable controls and remote monitoring for enhanced operational oversight. Its construction provides multiple material options for plungers, packings, and seals, tailored to withstand aggressive processing environments and specific application needs.

The homogenizer is designed with energy efficiency in mind, employing optimized motor control to reduce consumption. Maintenance and cleaning are simplified with a design that accommodates CIP (clean-in-place) systems for rapid, contamination-free operation. Fully compliant with industry regulations, it offers customization and engineering support for specialized operational requirements, ensuring it meets the rigorous standards of corporations across the food, personal care, and pharmaceutical industries.

Benefits

- Ensures consistent product quality through precise emulsification and size reduction.

- Supports continuous operation, maximizing throughput and minimizing process interruptions.

- Reduces energy consumption with optimized motor control, lowering operational costs.

- Customizable material selection enhances durability and compatibility with diverse media.

- Simplifies cleaning processes with CIP integration, ensuring quicker, more efficient maintenance.

- Applications

- Personal care, Chemical processing, Beverage processing, Beverages, Fats and oils, Pet food, Nutraceuticals, Plant-based food, Plant-based drinks and food, Dairy processing, Food processing, Baby food, Pharmaceutical

- End products

- Cream, Face creams, Protein shakes, Fish oil supplements, Almond milk, Pharmaceutical emulsions, Infant formula, Margarine, Lotions, Fruit juices, Liquid foundations, Milk, Suspensions, Soy milk, Carbonated soft drinks, Plant-based milk, Shortening, Wet pet food, Mayonnaise

- Steps before

- Mixing, Blending, Emulsification, Pre-heating

- Steps after

- Sterilization, Packaging, Filling, Cooling

- Input ingredients

- milk, cream, beverage, dairy, oil, nutraceuticals, fruit juice, personal care emulsions, plant-based ingredients

- Output ingredients

- homogenized milk, homogenized beverages, homogenized dairy products, emulsified oils, nutraceutical emulsions, fruit juice blends, personal care products, plant-based emulsions

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Homogenizer Type

- 5-plunger

- Valve Actuation

- Hydraulic

- Material Selection

- Custom-selected for application

- Working mechanism

- 5-plunger system

- Integrated steps

- Homogenizing valve assembly

- CIP/SIP

- Customizable for application-specific cleaning

- Batch vs. continuous operation

- Custom-selected

- Automation level

- Hydraulic actuation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Homogenizing valve assembly type

- Application-specific

- Plunger material

- Custom-selected

- Packing material

- Custom-selected

- Pump valve material

- Custom-selected

- Valve seat material

- Custom-selected

- Seal material

- Custom-selected

- Number of plungers

- 5

- Footprint

- Compact

- Control panel type

- Hydraulic actuation

- Homogenizing valve assembly

- Application-specific

- Hydraulic actuation

- Yes

- Plunger material

- Custom-selected

- Packing material

- Custom-selected

- Pump valve material

- Custom-selected

- Valve seat material

- Custom-selected

- Seal material

- Custom-selected

- Standard options

- Wide selection

- Special options

- Available