Making Protein Powder

Find innovative production technology for making protein powder and connect directly with world-leading specialists

It took the scientific community almost 70 years to agree on the name ‘protein’ and discard the popular alternative, proteid. But protein powder processing still needed another five decades to be commercialized in the 1950s. Once extraction and purification could be industrialized, protein powder soon became a basic staple supplement.

Select your protein powder process

Tell us about your production challenge

Obtain higher protein purification with chromatography

A critical step in protein powder processing is purification from other biological elements found in the cell. Most purifying techniques apply fractionation methods such as centrifugation followed by decantation.

Column chromatography takes advantage of the physical properties of the protein mixture to offer a powerful purification method. You may either target the protein itself or the other elements in the liquid solution as it percolates through a solid phase.

Perform protein power processing at low temperatures

Animal-derived protein finds optimum stability at a temperature of around 37 °C. However, its behavior changes once it is brought out of the cells, even if the temperature is maintained

Protein extraction yields better results at about 4 °C. Low temperatures allow greater control of the elements in the solution, while enzymes employed to break up protein perform better in a cooler environment.

Add a buffering component in the solution medium to stop denaturation

Proteins are prone to denaturation once extracted from their natural pH conditions. Protect your extract by adding a buffering component to your solution. Biological buffers with an acid dissociation constant of around 7, such as phosphate, offer good protection.

In addition, reducing agents shield your protein powder processing from oxidation. Dithiothreitol (DTT) or 2-mercaptoethanol are typical reducing agents, but the former shows higher effectiveness.

Soy protein extract delivers complete digestibility

Vegetables are also a good source of protein. Peas, hemp, and rice offer popular alternatives to animal-based protein, but they lack amino acids that the human body cannot synthesize.

On the other hand, Soy protein is the only plant-based alternative that meets all the essential requirements. Soy protein registers the highest score for quality on the Protein Digestibility Corrected Amino Acid Score (PDCAAS).

Insect processing is emerging as an alternative protein source

Agricultural entomology has come to the fore as an efficient protein source. Cricket protein, in particular, has attracted attention for its adaptability to human consumption requirements.

The ecological impact of insect farming is significantly lower than either crop or animal farming. Not only does it require less space, water, and energy, but insects can be reared on clean agricultural by-products such as surplus grains.

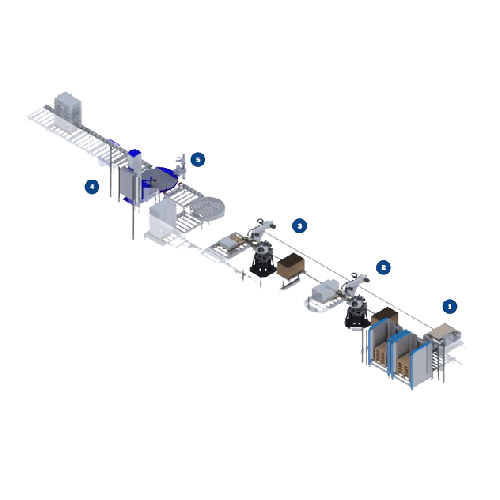

Processing steps involved in protein powder making

Which protein powder technology do you need?

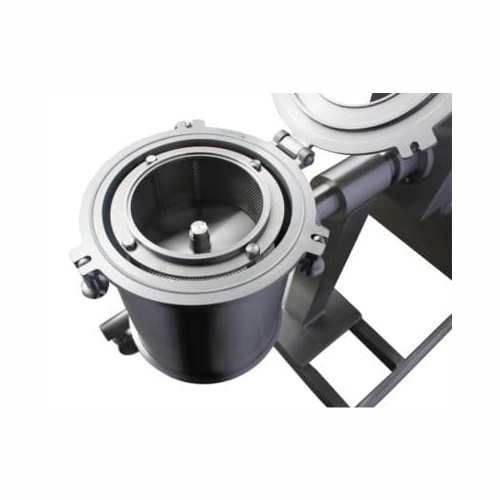

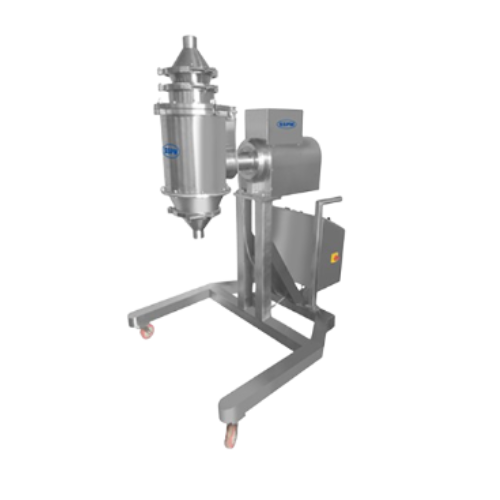

Clarifiers for pilot and lab scale applications

Ensure efficient separation and clarification at the pilot or lab scale wi...

Pharma separator for biopharma processing

Streamline your production with this advanced separator, designed to efficiently...

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

Clarifiers for plant protein recovery

Maximize protein yield and minimize waste with advanced clarification technology desi...

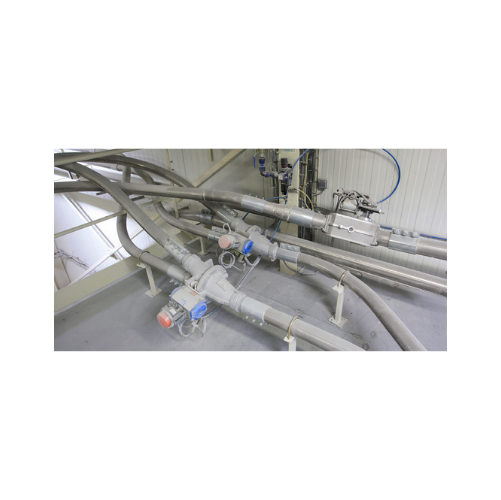

Piping solutions for breweries cold block area

Efficiently distribute and regulate media within your brewing process, ensu...

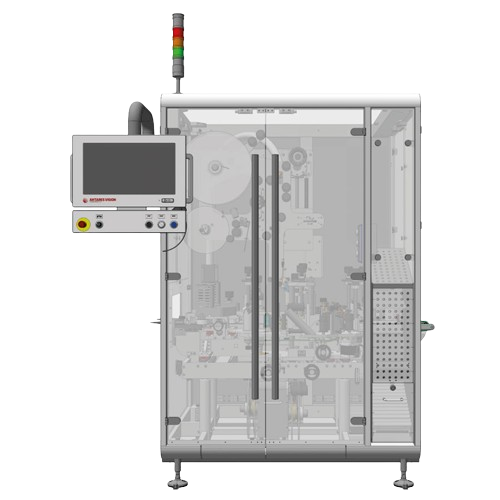

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminant...

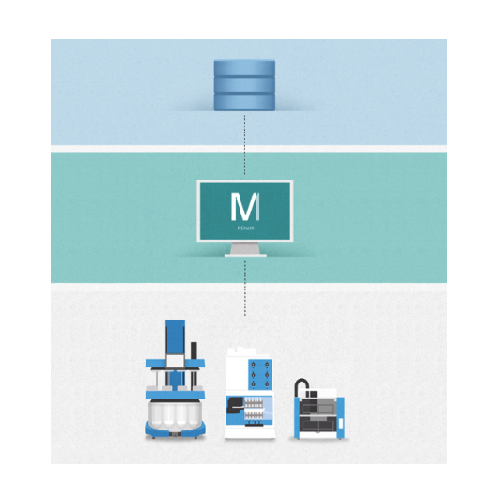

Spray dryer performance optimization system

Achieve unparalleled spray drying efficiency with real-time monitoring and con...

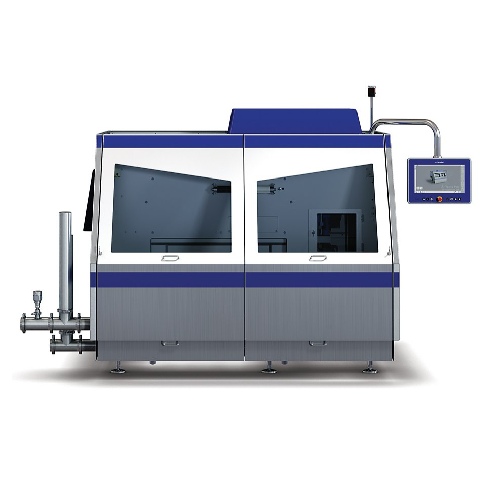

Sanitary cover for visual inspection

Ensure optimal hygiene and easy access in your production line with a transparent cove...

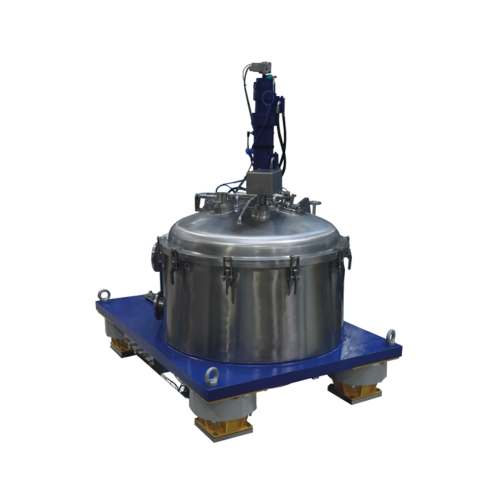

Vertical batch centrifuge for solid-liquid separation

Optimize your solid-liquid separation process with high-speed centr...

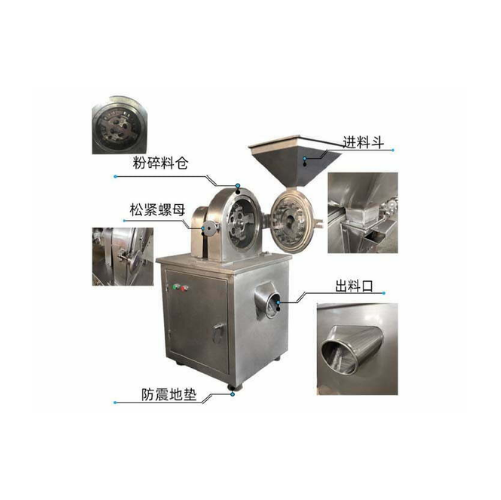

Planetary ball mills for fine grinding of materials

Optimize particle size and surface area in your samples with high-ene...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

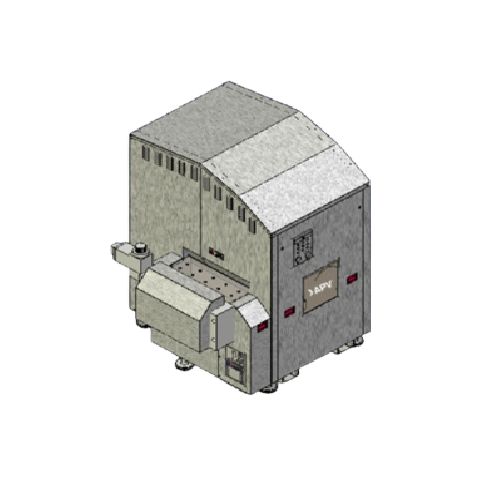

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

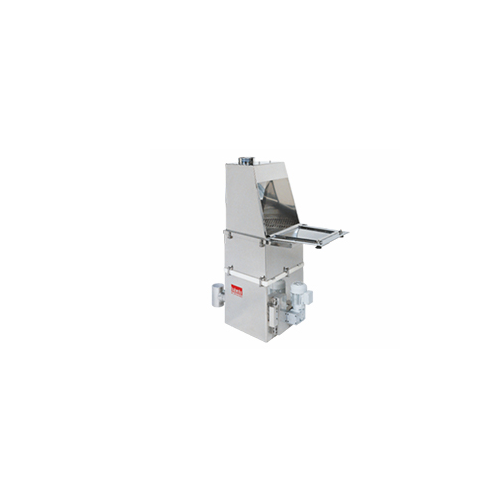

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Deagglomeration and delumping system

Ensure product integrity and streamline operations by effectively breaking down agglom...

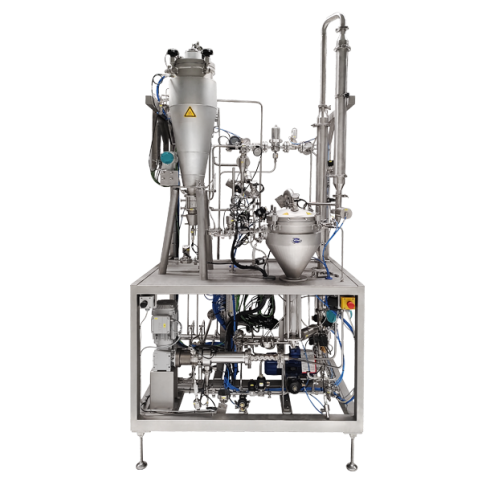

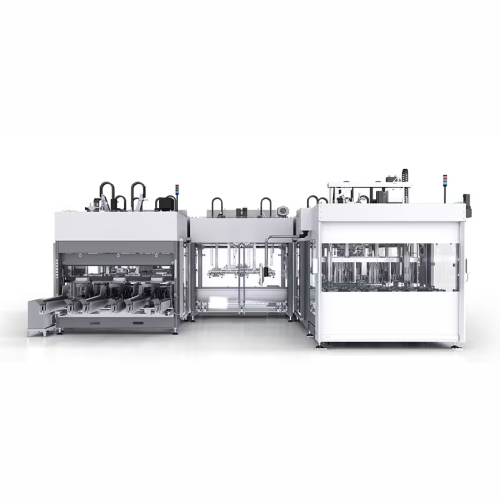

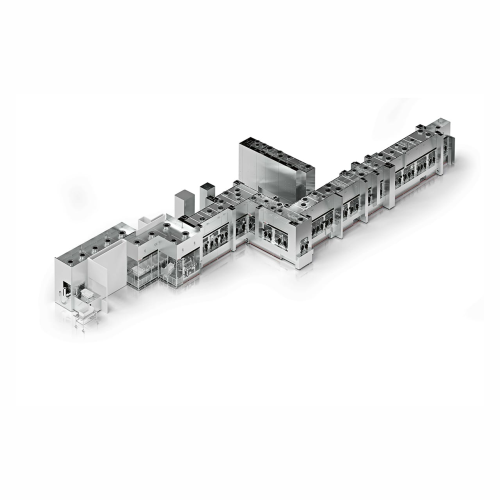

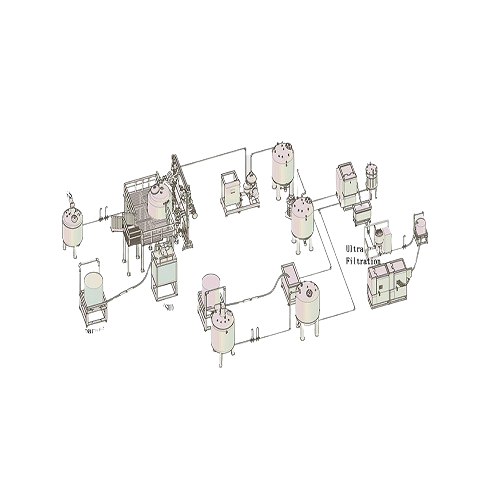

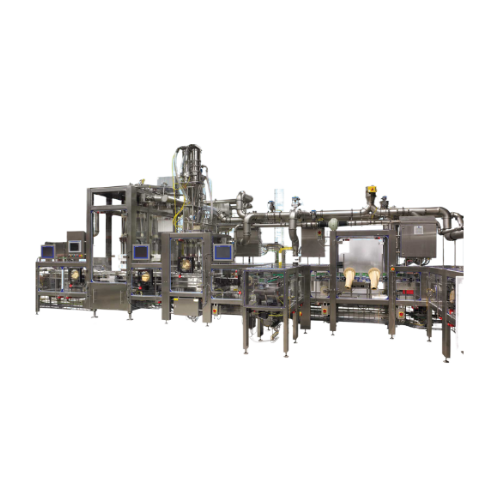

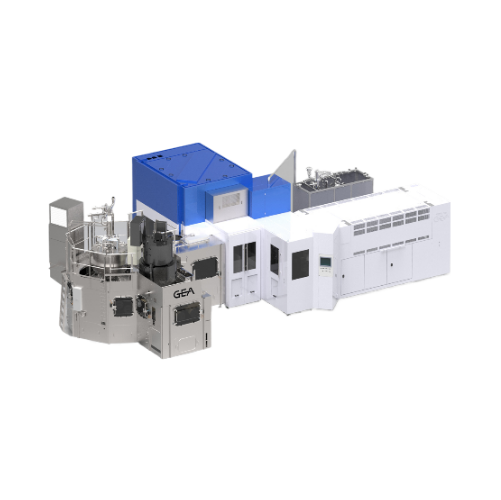

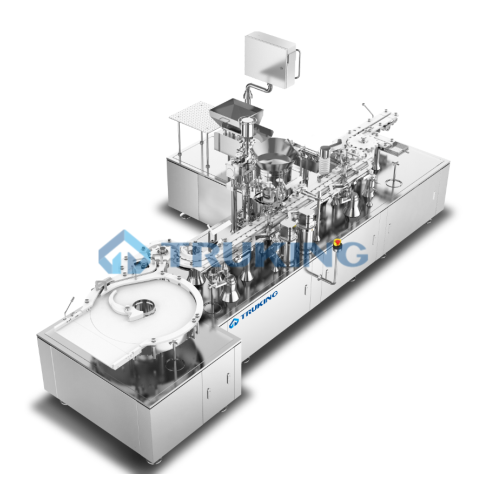

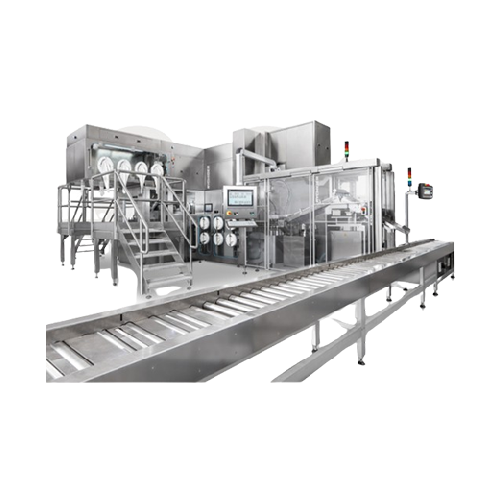

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

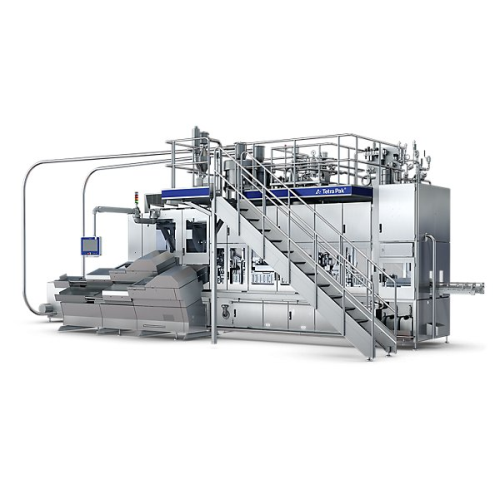

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

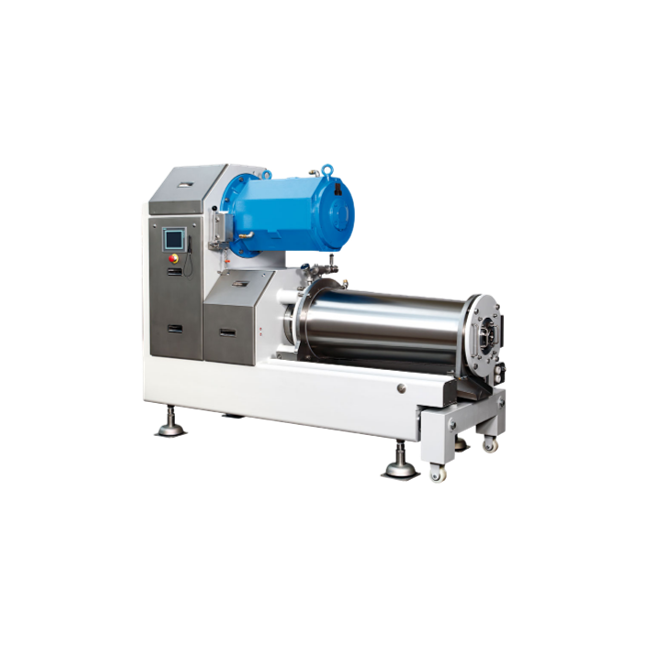

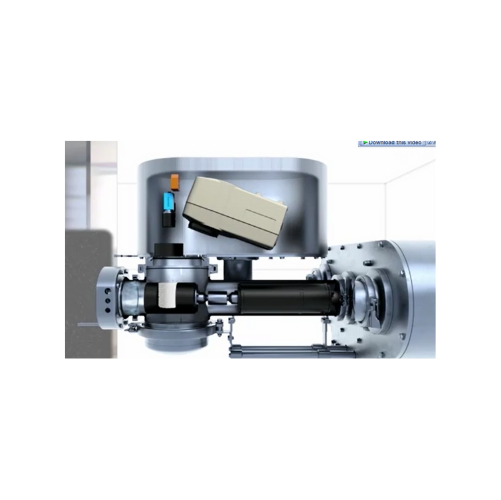

Horizontal colloid mill for precise grinding

Achieve precise particle size reduction and reproducible results with our adv...

Dry scroll vacuum pumps for laboratories and manufacturing

Ensure a clean, oil-free environment with advanced dry scroll...

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Air filtration system for dairy and food powder processing

Optimize powder processing with advanced air filtration, ensu...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Industrial bag tie-wrapping solution

Ensure your bulk packaging is reliably sealed with a tamper-evident tie-wrap, allowing...

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Capsule packaging system for individual gusseted bags

Streamline your coffee capsule production with high-speed, precisio...

In-line production of fine emulsions

Achieve homogenous emulsions with precise control, reducing the risk of lump formation...

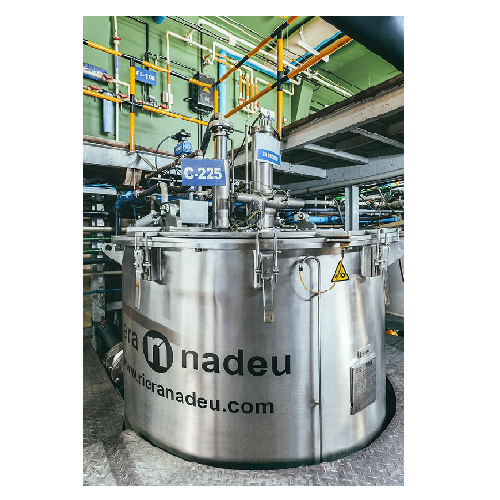

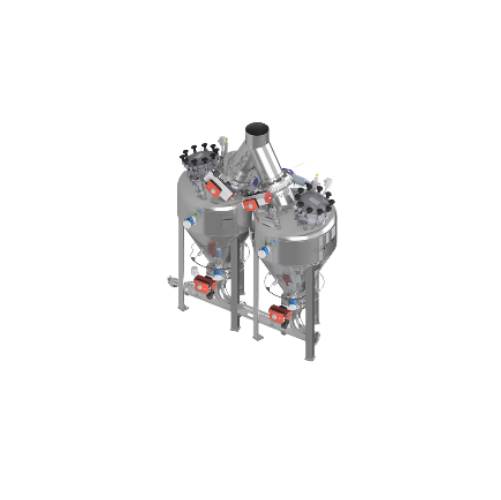

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

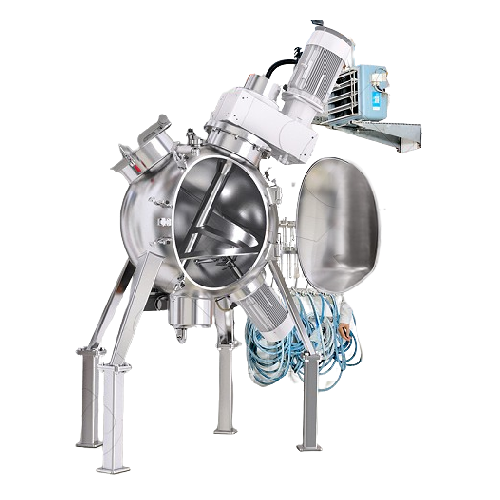

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

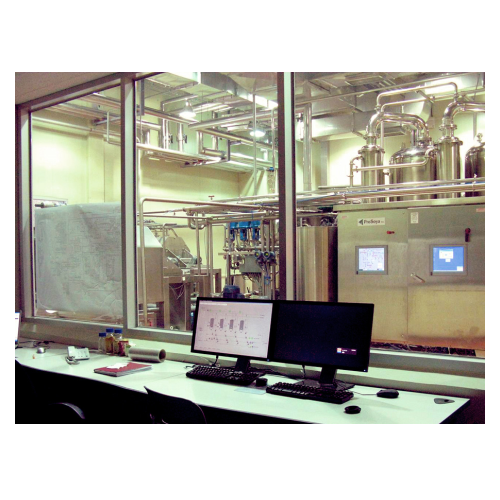

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

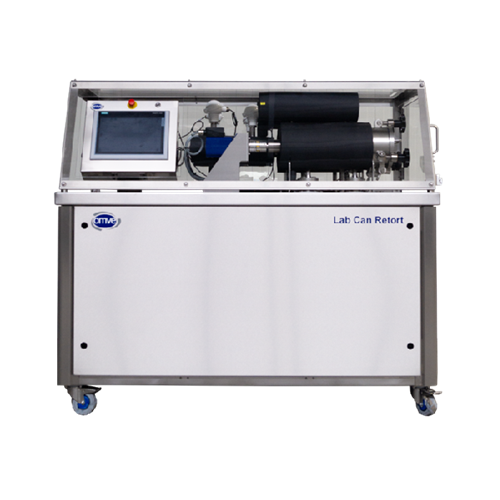

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

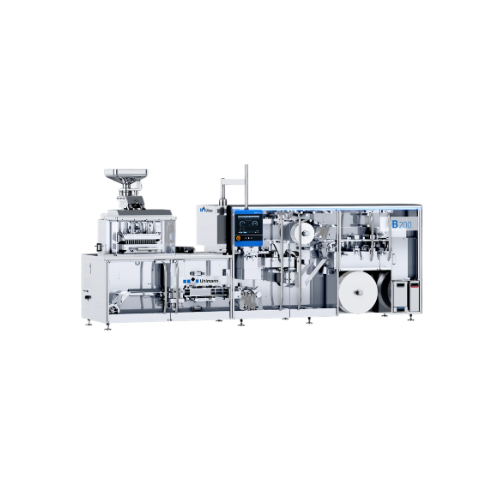

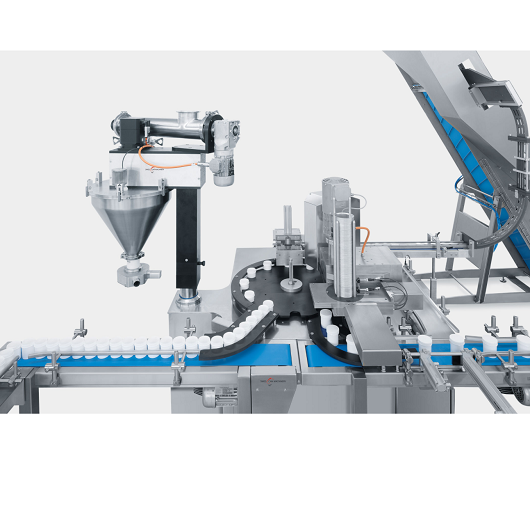

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

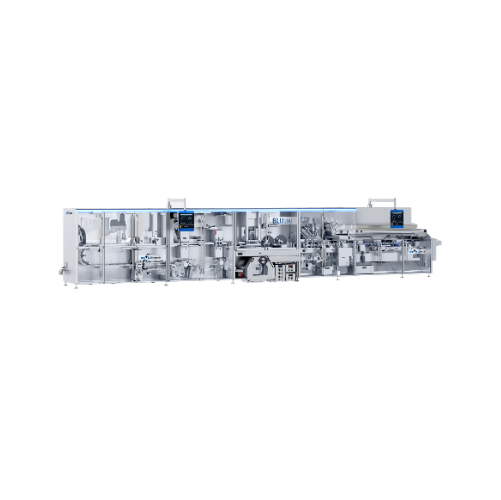

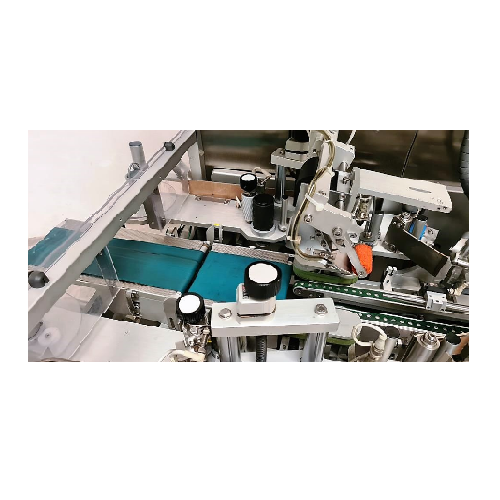

Continuous motion micro dosing system for nutraceutical powders

Streamline your powder processing with a high-speed, con...

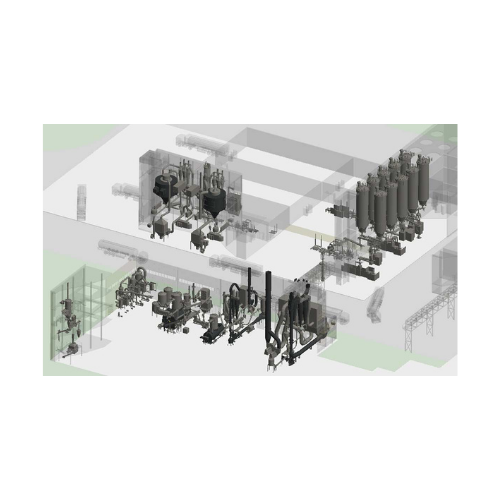

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

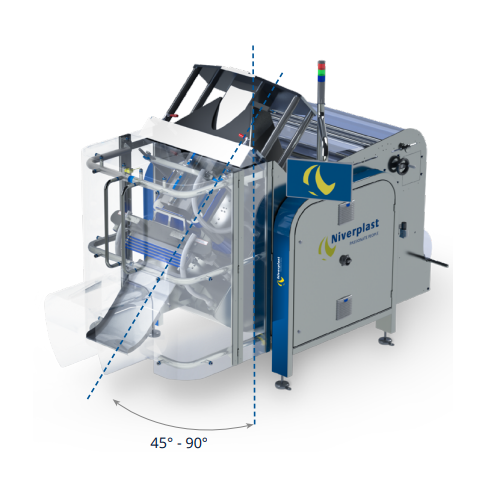

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

Automated system for placing bags in boxes and crates

Streamline your packaging process with high-speed bag placement tha...

Touch-free layer packaging for bakery products

Optimize your packaging line with a touch-free solution that ensures hygien...

High-speed bag placing system for e-commerce fulfillment centers

Optimize your packaging line with a high-speed system t...

Automated bag folding for packaging

Streamline your packaging operations with a high-speed solution that seamlessly integra...

Automatic bag sealing system for packaging operations

Optimize your packaging efficiency with this high-speed sealing sys...

Compact palletizing solution for limited space

Optimize your space with versatile palletizing that adapts to diverse produ...

Automated paper bag placing system

Efficiently automate the placement of paper bags into totes or boxes with precision and ...

Case erecting and bag placing system

Streamline your packaging process with a compact system that integrates case erecting ...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Ibc blender for industrial powder mixing

Streamline your powder mixing with rapid batch changeovers and reduced cleaning do...

Powder packing module for consistent flow

Enhance your production efficiency with streamlined powder packing that ensures ...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Small powder recipe formulation system

Streamline the formulation of diverse powder recipes with seamless integration into ...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Sachet filling and closing system

Optimize your production line with a versatile solution designed to fill, seal, and count...

Pharmaceutical metal detector for powder and granule inspection

Ensure product integrity by efficiently detecting metal ...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Powder handling systems for battery production

Optimize your battery production with a versatile powder handling system th...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Oil cooling tank for fast product cooling

Accelerate your cooling process efficiently with an advanced oil cooling tank fe...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Automated headspace inspection for parenteral containers

Ensure the integrity and quality of pharmaceuticals by inspectin...

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

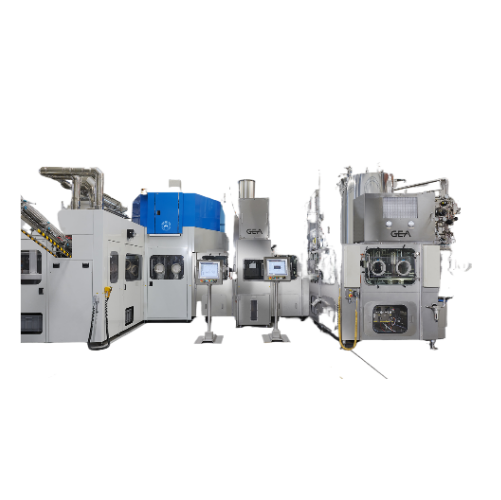

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

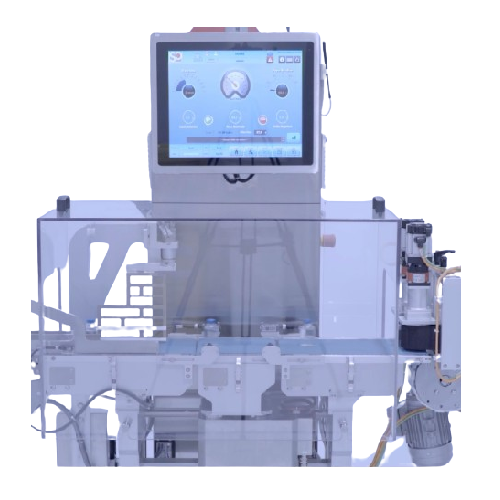

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Pilot spray dryer for high-value proteins and nutraceuticals

Optimize powder development with precise pilot-scale spray ...

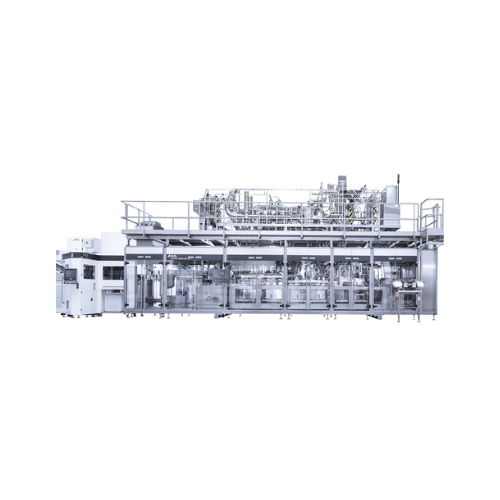

Protein drying system for dairy products

Optimize your dairy production with a customizable drying system designed for effi...

Tall form bustle dryer for dairy and food products

Experience efficient drying and precise moisture control with this inn...

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

Dosing and tray handling lines for ready meals

Ensure precise dosing and seamless tray handling for a variety of ready mea...

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Industrial ultrasonic liquid processor for high volume applications

For large-scale liquid formulations, achieving cons...

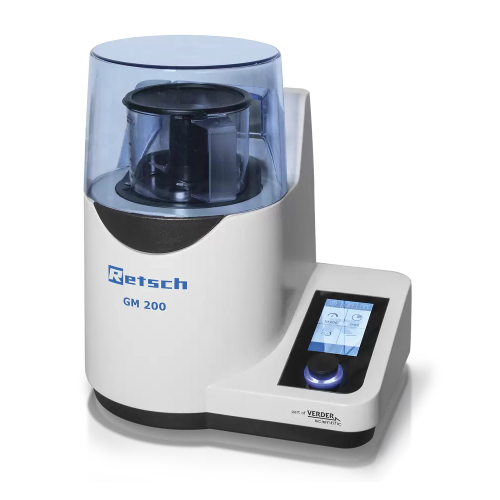

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Super high shear inline disperser for nanoparticle production

Achieve unmatched particle size reduction with cutting-edg...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Ultrasonic liquid processor for medium-scale production

Streamline your production with a robust ultrasonic solution capa...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

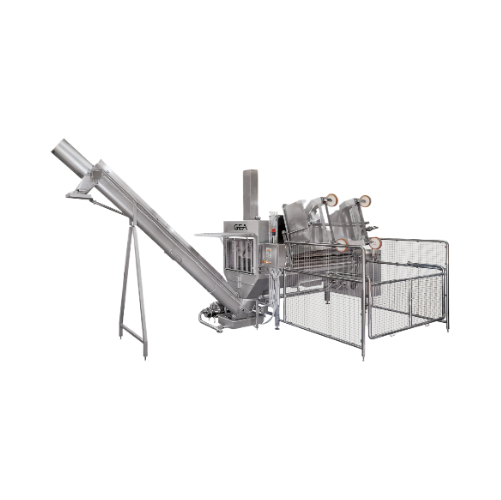

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Automated Cip system for small facilities

Ensure impeccable hygiene with a mobile cleaning system designed to efficiently ...

Powder liquid mixer for pectins and starches

Struggling with clumpy, undissolved granules in your mixtures? This innovativ...

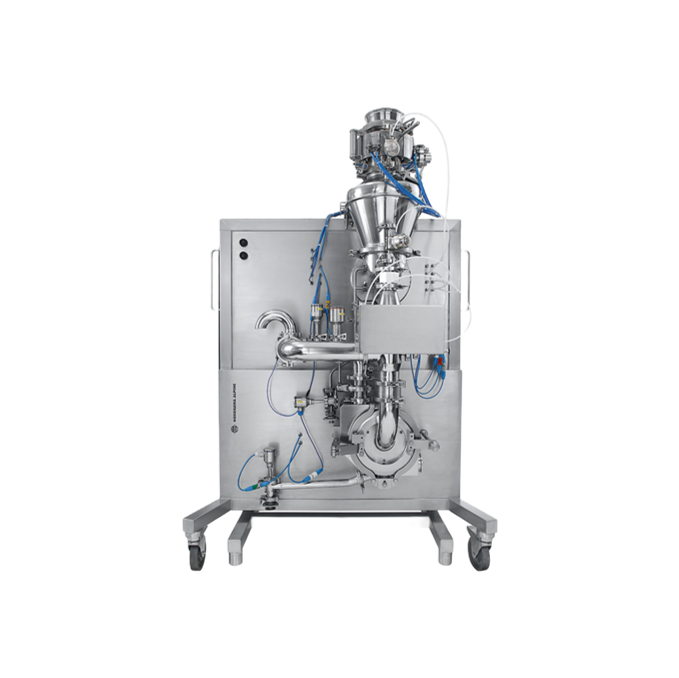

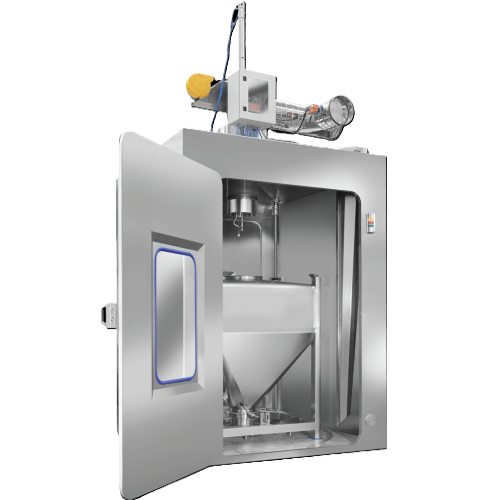

Single-pot granulation processor for pharmaceutical applications

For manufacturers needing precise granulation and dryin...

Sterile bag filling and closing system

Ensure precision and sterility in multi-chamber bag filling for liquid and powder ph...

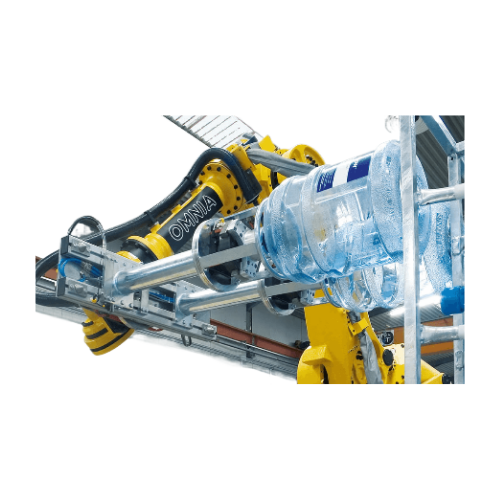

Rotary unscrambler for plastic bottles

Streamline your bottling process with a solution that efficiently sorts, orients, an...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

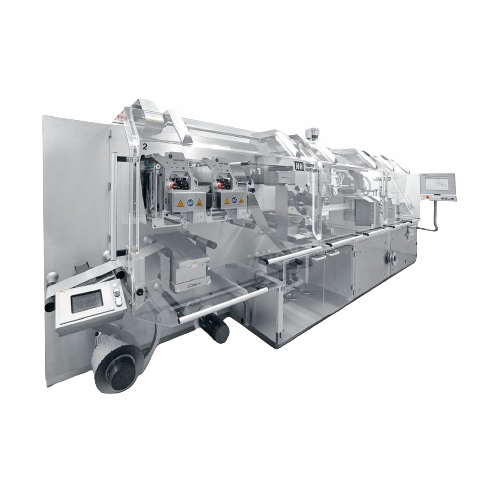

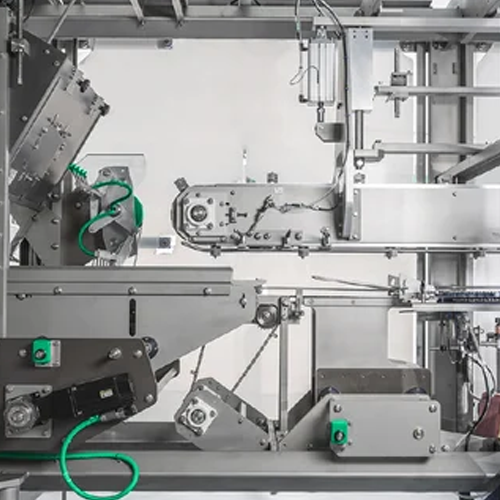

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Fluid bed processor for pharmaceutical granulation and drying

Achieve precise drying, granulation, and coating of pharma...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

Cone mill for particle size reduction

For precise particle size reduction, the cone mill offers flexible screening options ...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

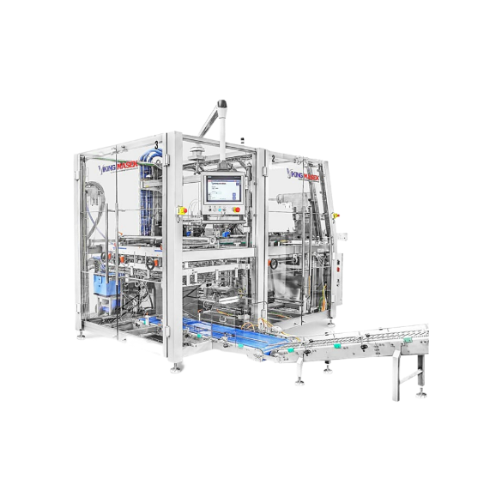

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

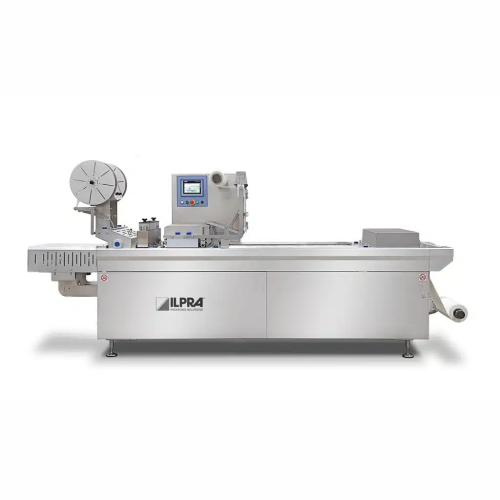

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

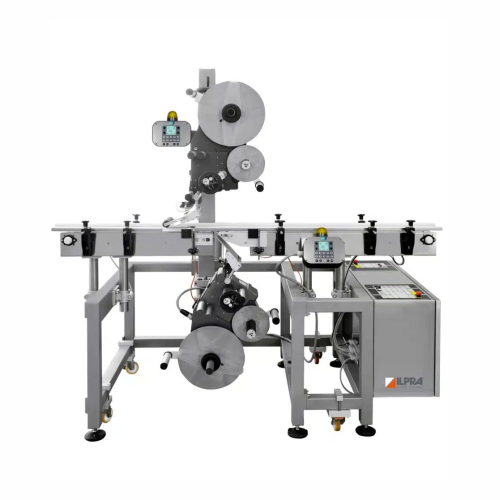

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

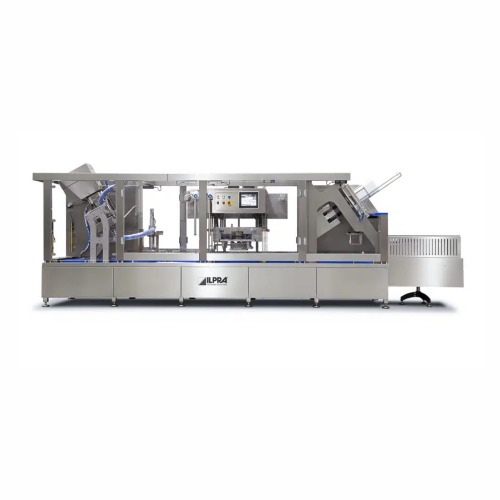

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

Purified water storage and distribution for pharmaceuticals

Ensure seamless water quality for critical pharmaceutical pr...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Laboratory vacuum dryer for heat-sensitive materials

Optimize moisture control in heat-sensitive materials with precise a...

Conical paddle mixer for accurate powder blending

Achieve precise blending of fragile powders and liquids with a versatil...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

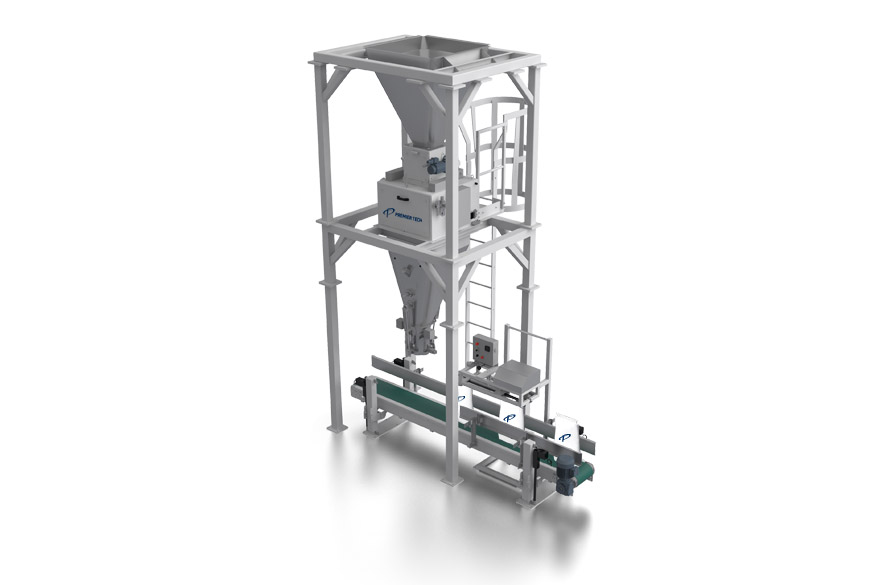

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Leak detection for pharmaceutical containers

Ensure the integrity of your liquid products in high-speed production by dete...

Vertical vacuum dryer for heat sensitive products

Achieve optimal drying and mixing for your heat-sensitive and shear-sen...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Pilot plant filter dryer for small scale production

Optimize filtration and drying processes in your pilot plant with a v...

Vertical peeler centrifuge for pharmaceutical industry

Ensure thorough separation and purification of products with this ...

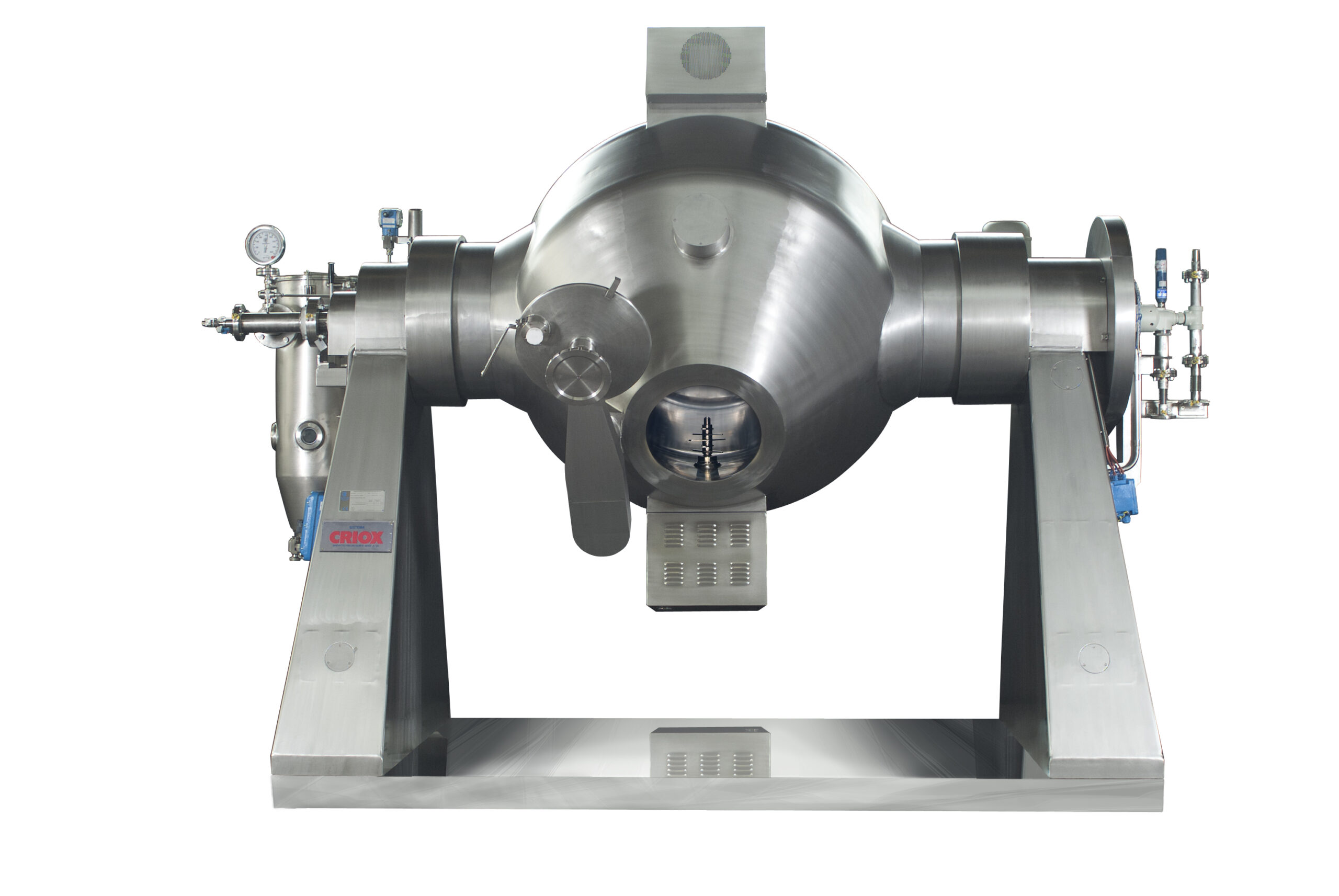

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Horizontal pilot plant centrifuge for chemical processing

Enhance your R&D and pilot-scale processes with a centrif...

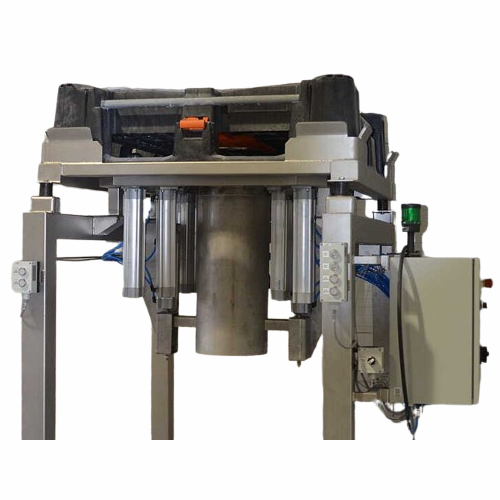

Inverting filter centrifuge for high-potent Api products

Achieve optimal separation and reduce residual moisture with pre...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

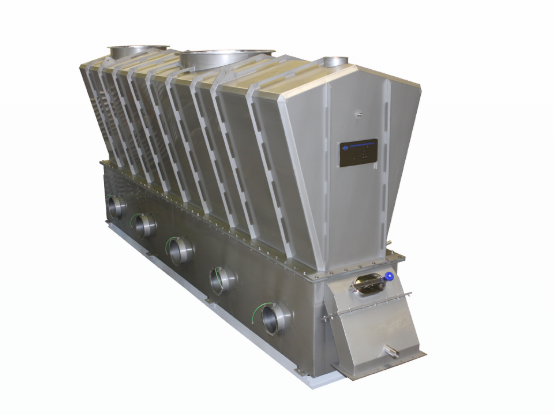

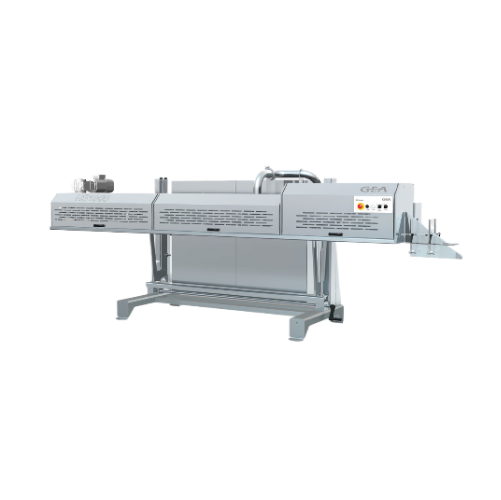

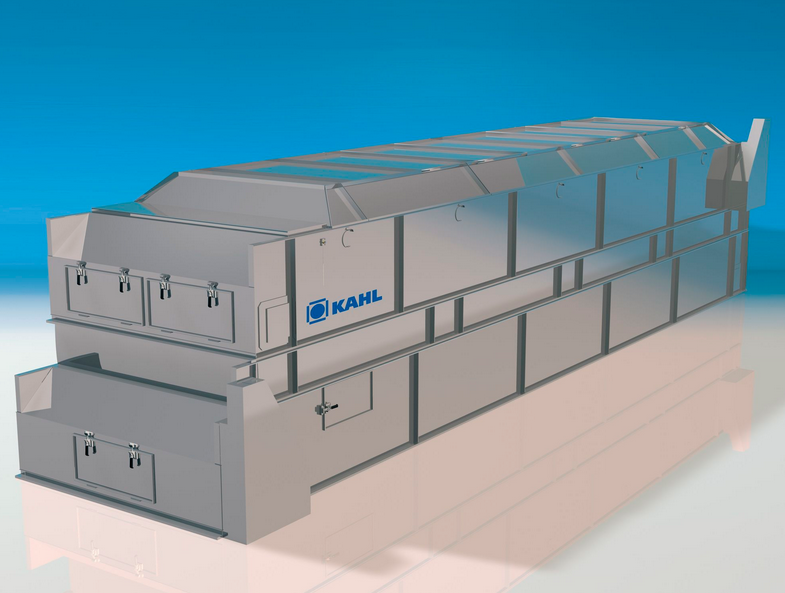

Continuous dryer for large production volumes

Achieve high-speed moisture removal with precision and minimal thermal impac...

Pharmaceutical powder bag filling system

Ensure precision in pharmaceutical formulations with a system that fills high-spee...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Ultra-hygienic vacuum conveyor for pharmaceutical and food industries

Streamline material handling with this ultra-hygi...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Industrial container and drum handling solution

Effortlessly maneuver and position heavy containers such as IBCs and drums...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Industrial drum tumblers for uniform batch processing

Achieve precise mix uniformity in your batches with drum tumblers, ...

Industrial container lifting system

Optimize your production line with a versatile lifting solution designed to safely hand...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Ibc tumbler for uniform batch mixing

Achieve consistent and homogenous mixing of powders, granules, and solid products with...

Juice storage tank with hygienic and cooling options

Ensure optimal freshness and stability of juices and beverages with ...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Big bag pallet unloader for bulk products

Efficient and reliable solution for unloading and transporting powders and bulk ...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

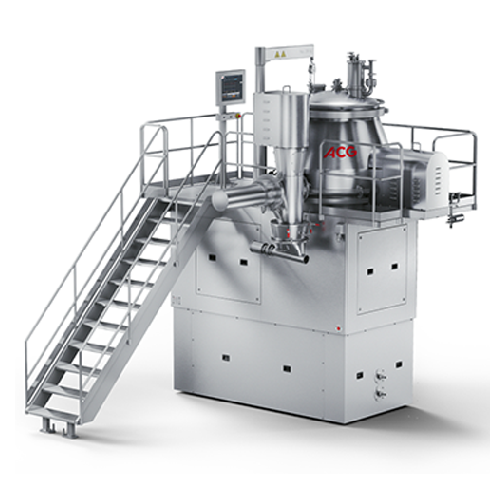

Pilot High shear granulator for wet granulation

Achieve consistent particle sizing and superior homogeneity in your powder...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Roll compactor system for dry granulation

Achieve consistent tablet hardness and increased powder density with a versatile...

Roller compaction system for dry granulation

Achieve precise densification and consistent powder granulation with a system...

Pilot blender for small batch powder blending

Optimize your R&D processes with this versatile mobile blender, ideal f...

Pharmaceutical powders and granules dry blending

Achieve uniform blending of diverse powder and granule formulations with ...

Continuous direct compression system for tablet production

Achieve seamless continuous direct compression by integrating...

Vacuum transfer system for powders and granules

Effortlessly transfer and manage powders and granules with seamless integr...

Internal and external bin washing cabinet

Streamline your sanitation process with automated bin cleaning that ensures thor...

Pharmaceutical powder blender

Ensure uniform mixing of pharmaceutical powders and granules with advanced blenders designed f...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

Laboratory high speed mixer for powders and granules

Achieve homogenous blending of powders and granules efficiently with...

Advanced friability and abrasion testing solution

Ensure precise compliance in pharmaceutical tablet testing with this in...

Lab-scale ball mill for crystalline material grinding

Effortlessly grind and mix crystalline materials into fine powders ...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

Dissolution testing software for compliance and efficiency

Ensure data integrity and streamline compliance with a robust...

Digital dissolution tester for high volume testing

Optimize high-volume tablet and supplement testing with precise contro...

High-speed centrifuge for biomass and particle harvesting

Achieve high-speed particle separation and biomass harvesting ...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Fluid bed processor for granulating, drying, and coating in pilot scale

When scaling from laboratory to production, rel...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

Industrial hammer mill for grinding and sifting

Ensure precise particle size reduction and consistent product quality with...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

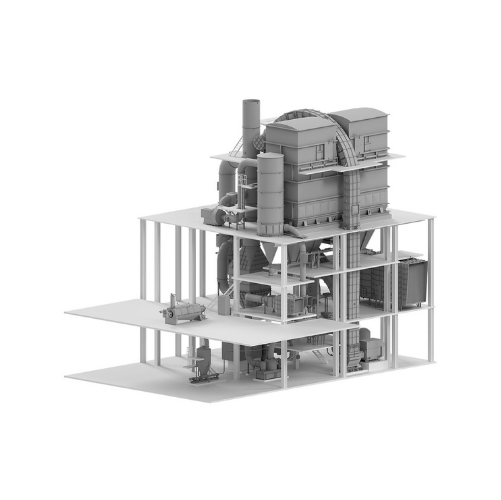

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

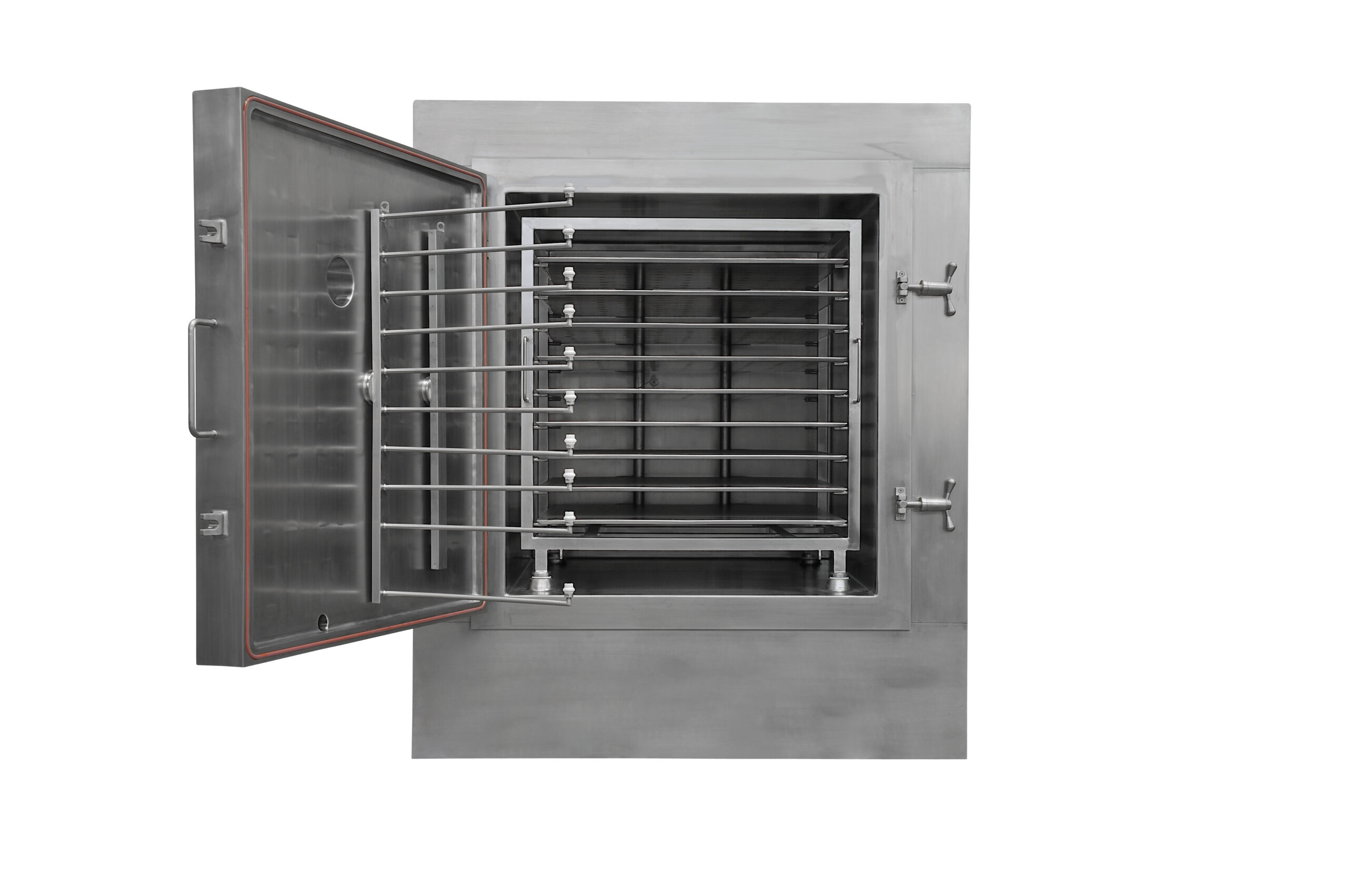

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

Vertical seed conditioning system for oil extraction

Ensure optimal oil yield and quality from oilseeds by employing a ve...

Continuous deodorizing for oils and fats

Achieve optimal purity and flavor in oils and fats with advanced continuous deodor...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

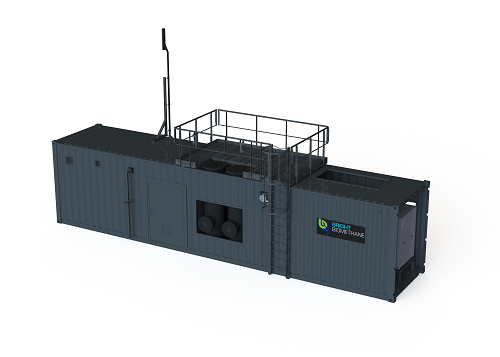

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Seed hull removal and condition system

Optimize your seed processing efficiency by effectively removing hulls and foreign m...

Biodiesel pretreatment system

Optimize your biofuel production by efficiently reducing impurities and unwanted components, e...

Flash desolventization system for oilseed processing

Achieve rapid desolventization with minimal heat exposure, preservin...

Laboratory pellet press for testing and formulation

Achieve precise pellet formulation and performance testing with versa...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

Sanitary bulk solids receiver for food and pharma

Ensure precise control over bulk solid transfer with a system designed ...

Laboratory cone mill for even grinding

Achieve consistent particle size for laboratory powders with precision calibration a...

Mini laboratory mixer for tabletops

Optimize your lab’s mixing precision with this compact tabletop bin mixer, design...

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

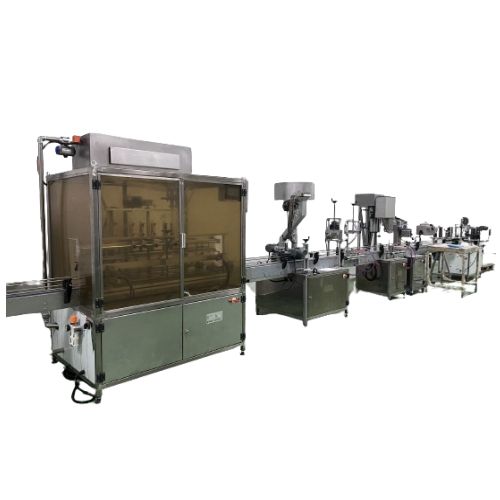

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

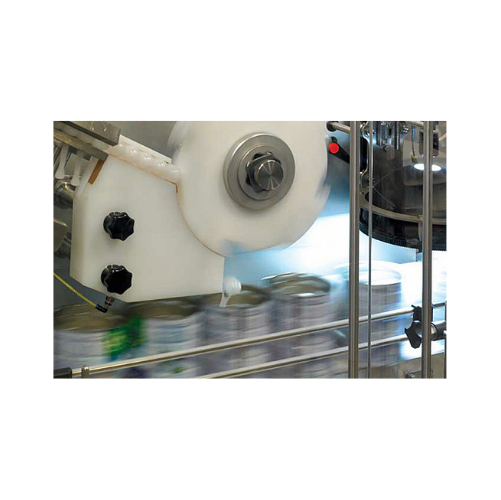

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Industrial filter centrifuges for high solids content processing

Optimize processing of high-solid slurries with efficie...

High temperature clean room ovens

Achieve precise environmental control for heating, drying, and sterilizing sensitive mate...

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

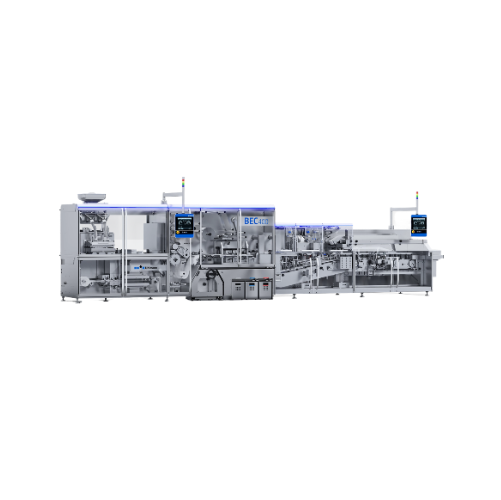

Continuous motion powder dosing system

Ensure precise dosing of pharmaceutical and nutritional powders with this continuous...

Intermittent motion powder dosing and capping system

Ensure precise powder dosing and secure capping in one seamless step...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

High speed stick packaging solution

Optimize your packaging line with this high-speed vertical solution, designed to effici...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Infrared speeddigester for nitrogen determination and chemical oxygen demand

Effortlessly enhance your laboratory thro...

Homogenizer for food and feed analysis

Achieve precise homogenization and particle size distribution with this high-speed b...

Parallel sample evaporator

Process multiple samples efficiently with precise control, ensuring quick evaporation and consist...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Inert loop for safe organic solvent spray drying

Ensure safe handling and efficient recovery of organic solvents in spray ...

Moisture analyzer for flour and tobacco

Optimize your moisture measurement process with precision and speed, ensuring quali...

Industrial sample preparation mill

Ensure precise moisture, protein, and fat content analysis with this reliable milling so...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

Laboratory homogenizer for dairy and biotech applications

Ensure precise particle size reduction and consistent texture ...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Big bag discharge station for bulk material handling

Ensure low-dust and efficient discharge of bulk materials with a sys...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free docking collar for containers and bins

Achieve seamless, dust-free connections between containers and processing...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Dust-tight docking for dosing units to bulk solids containers

Ensure seamless, dust-free transfer and dosing of bulk sol...

Cost-effective dosing container for minor ingredients automation

Optimize your production by streamlining ingredient han...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

Batch automation system for fast and precise weighing

Achieve unmatched precision and speed in batch processing with this...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

Jet mill for micronizing pharmaceutical powders

Achieve precise particle size reduction with a jet mill that leverages hig...

Continuous wet granulation equipment

Optimize your production line with continuous wet granulation, seamlessly transforming...

Hybrid bioprocess system for cell culture and purification

Streamline your bioprocessing operations with a versatile sol...

Cip cleaning system for industrial processing lines

Ensure thorough removal of residue and contaminants from your product...

Standalone print & check system for cartons

Ensure data integrity and compliance in packaging operations with a versatile ...

Vacuum drum filter for solid/liquid separation

Optimize your solid/liquid separation process with a versatile vacuum drum ...

Solid/liquid extractor for high-yield functional nutrient extraction

Maximize extraction efficiency and elevate product...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Conical vacuum dryer for viscous materials

Achieve precise drying and mixing of moist and viscous materials, ensuring cons...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Miniature auger filler for precise powder filling

Achieve precision filling with a compact, bench-top auger solution desi...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Special purpose auger filling systems for diverse industries

For manufacturers handling precise dosing, our advanced aug...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

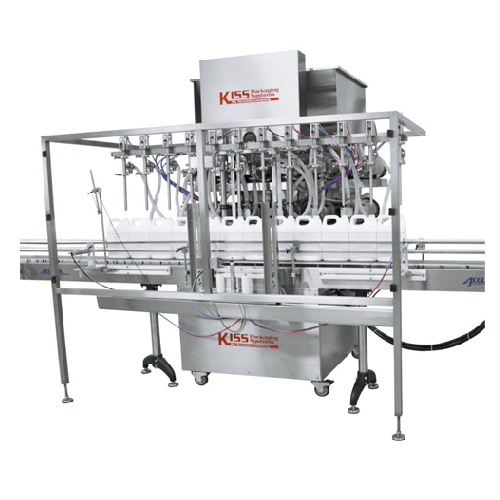

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Cross-flow membrane filtration for lab use

Optimize laboratory filtration processes with compact, dual-membrane testing to...

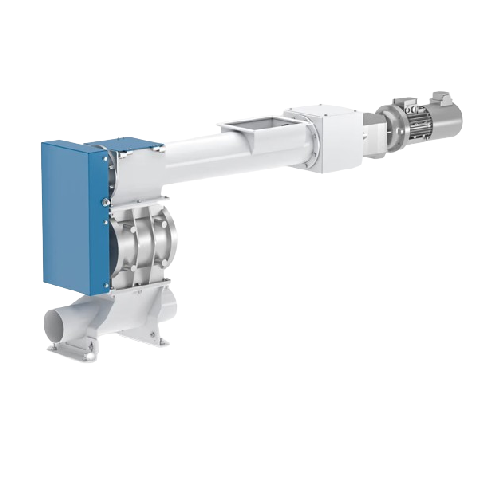

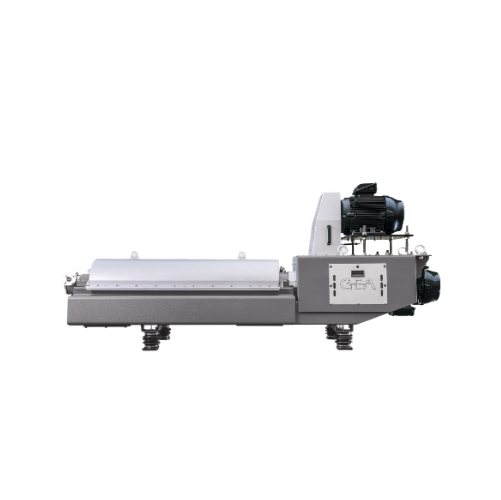

Decanter centrifuge for protein extraction

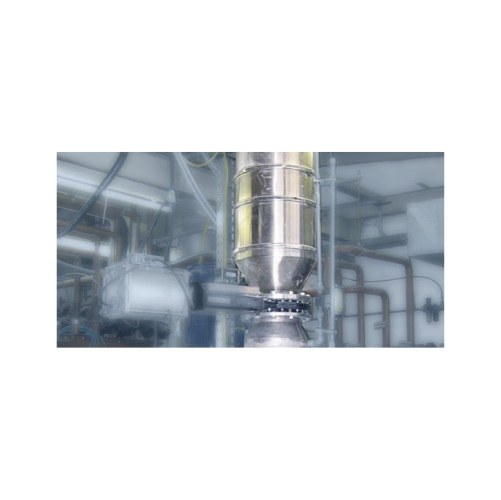

Efficiently enhance your recovery of valuable proteins and fats with customizab...

Rising film evaporator for concentration of viscous liquids

Effortlessly concentrate low-to-medium fouling and highly vi...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Hybrid powder mixer for powder-liquid blending

Achieve consistent powder-liquid blends with reduced processing times and e...

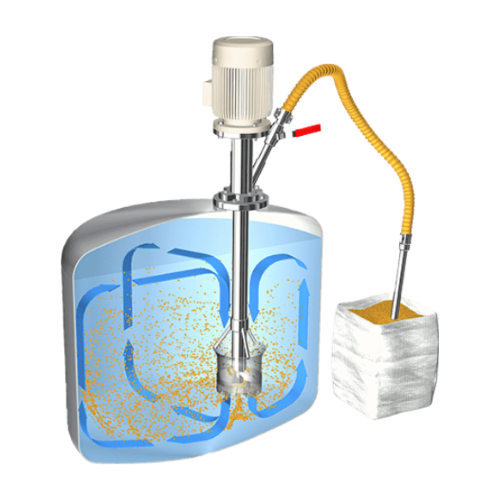

Rotary jet mixer for efficient liquid, gas, and powder mixing

Achieve seamless integration and efficiency in liquid, gas...

Pharmaceutical roller compactor for dry granulation

When precision and uniformity in tablet production are crucial, optim...

Industrial grater and shredder for pharmaceutical and chemical applications

Optimize your production line with a versa...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Lifting column for drums and bins

Optimize your powder handling operations with a versatile lifting solution designed for p...

Mobile bin blender for mixing and homogenizing dry powders

Ensure thorough powder uniformity and eliminate cross-contami...

Lifting column for plastic boxes in pharmaceutical processing

Optimize your tablet and powder processing by seamlessly l...

Stainless steel pharma bin for powder containment

Ensure precise powder handling and containment with this stainless stee...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

Mobile lifting column for drum handling

Streamline your powder and drum handling operations with this versatile mobile lift...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Compressed air loaders for material conveying

Efficiently convey diverse materials with minimal operator intervention, usi...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Sterilizer for finished liquid products

Ensure precise thermal control and asepsis in your liquid product sterilization pro...

High-shear mixer granulator for small batches

Achieving consistent particle size and mix uniformity in pharmaceutical and ...

Versatile fluid bed combo for granulation and coating

Optimize lab-scale R&D with an adaptable fluid bed system, sea...

Intermediate-scale fluid bed system for drying and granulation

Achieve precise drying and granulation with this versatil...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid bed granulator for pharmaceutical applications

Optimize your granulation and drying processes with advanced fluid-b...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Fluid bed combo for top-spray granulation and wurster coating

Optimize your batch processing with a versatile system cap...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

In-line gassing system for powder processing

Optimize shelf life and quality of your powdered products by effectively redu...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

High-speed container reject system

Ensure product integrity by swiftly rejecting non-compliant containers at speeds up to 3...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Multi-stage centrifugal pump for hygienic applications

Ensure optimal hygiene and performance in your liquid processing w...

Self-priming side channel pump for high gas content media

When handling media with high gas content, achieving efficient...

Centrifugal pumps for hygienic applications

Ensure precise liquid handling for high-stakes applications with this hygienic...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

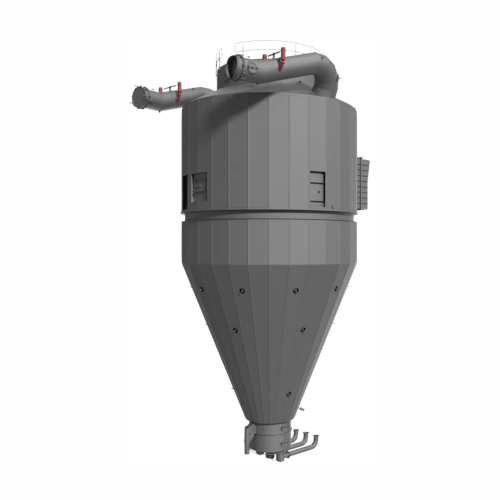

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

Square sieve for removing foreign bodies and grain sizes

Achieve precise material separation and enhance product purity w...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

Micro-ingredients doser for precise powder additives

Maintain precision and hygiene in your production line with a specia...

Powder and granulate premixer

Achieve consistent, homogenous blends of powders and granulates with our advanced premixing te...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Industrial bucket elevator for efficient product conveyance

Enhance production efficiency by elevating and transferring ...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

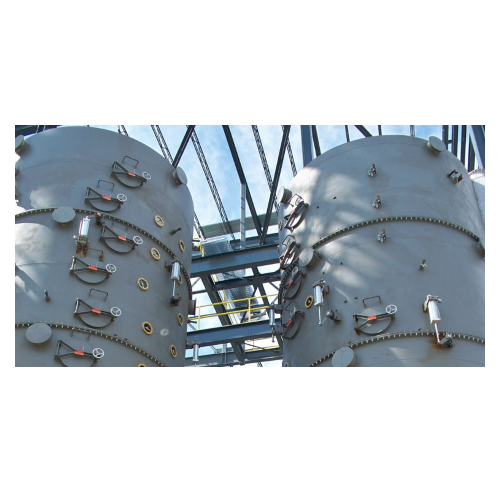

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Industrial vibrating sieve for powder and lump separation

Ensure precise separation of powders and lumps with this oscil...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Dense phase vacuum conveying system for powder handling

Effortlessly transport delicate powders and fragile granules with...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Rotary tube selector valve for powder conveying

Streamline your pneumatic transport system with a robust solution that div...

Auger powder sampler for industrial quality control

Ensure precise quality control by integrating an auger powder sampler...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

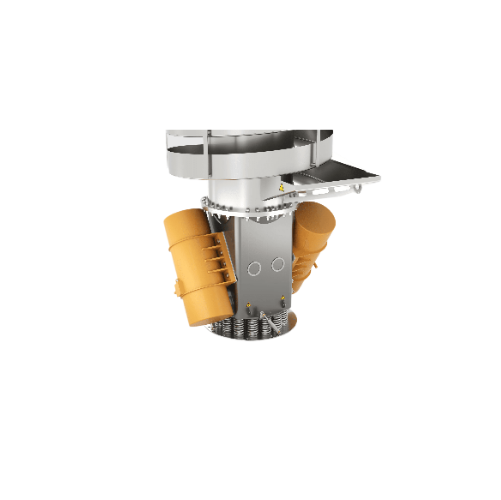

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Automatic bag slitting and emptying for powders

Streamline your powder-processing operations by seamlessly integrating bag...

Dense phase pressure conveying system

Efficiently transport high-capacity powders across long distances with precision and ...

Pharmaceutical intermediate bulk containers (ibc)

Streamline pharmaceutical production with precise containment and trans...

High shear powder dissolver for homogeneous products

Achieve consistent powder-liquid blends effortlessly with a compact ...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Tubular heat exchanger for thermal treatment of viscous products

Optimize efficiency in heating, cooling, and pasteuriza...

Curd handling and cutting for cheese production

Optimize curd processing with precise cutting and feeding, ensuring consis...

Pilot plant homogenizer for continuous operation

Achieve consistent fluid textures and prolonged shelf life with high-pres...

Laboratory homogenizers for nanoparticles and emulsions

Tackle the challenge of achieving consistent nano-scale dispersio...

Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an auton...

Robotic palletizer for food and beverage industries

Enhance your production line’s efficiency with a flexible robot...

3-in-1 food package inspection system

Ensure your packaged food products meet safety and regulatory standards with a system...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Bag, box, and drum container handling solutions for powder products

Optimize the flow and integrity of your powder pack...

Loose package conveyor systems for packaging lines

Optimize your packaging line operations with advanced conveyor systems...

Hygienic filling system for short shelf life milk

Optimize your cold-chain distribution with a filling system engineered ...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Aseptic blow fill system for beverage bottling

Designed for high-speed aseptic bottling, this system ensures sterility thr...

Decontamination blow fill system for beverages

Optimize your beverage production with a technology that integrates preform...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Hygienic powder filling system for low throughput

Ideal for compact production facilities, this filling system efficientl...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Industrial hot air system for spray dryers

Ensure consistent hot air delivery for critical drying processes, enhancing ene...

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

Lab-scale spray dryer for small volume powder samples

When developing new formulations, achieving consistent powder quali...

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

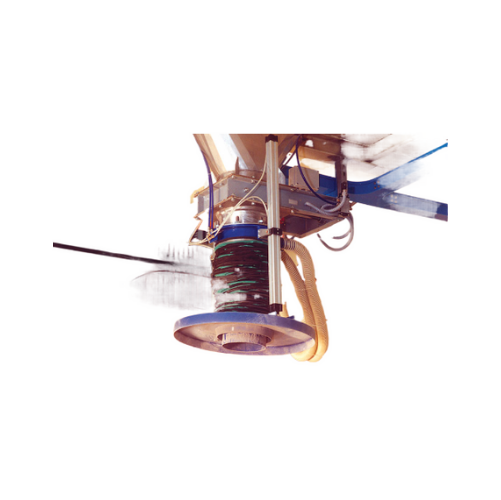

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Pharmaceutical freeze dryer for large-scale production

Streamline your freeze-drying process with precision-engineered ly...

Clean purge system for spray dryers

Enhance safety and efficiency by preventing fire risks in spray dryers while improving ...

Co monitoring system for spray dryers

Ensure safety and prevent costly disruptions in your spray drying process by monitori...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Clarifying decanter for starch recovery

Ensure optimal dewatering and separation of starch, pulp, and fibers with this high...

Clarifying decanter for food ingredient processing

Optimize your protein recovery and ensure high-quality separation with...

Pure steam generator for industrial applications

Ensure the highest levels of steam purity and precise pressure control fo...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Vacuum hopper loader for automatic feeding of powders and pellets

Optimize your material handling with seamless automat...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

Fluidizing bed for bulk material discharge

Optimize your material flow with a fluidizing bed designed for seamless dischar...

Inline disperser for food production

Quickly achieve stable, agglomerate-free dispersions and emulsions with minimal manual...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Loading bellows for drums and Ibcs

Ensure dust-free loading of bulk solids into confined spaces with compact, pneumatically...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Vibratory feeder for dosing powders and bulks

Ensure precise feeding of powders and bulk materials with a system that inte...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

Lump breaker for breaking agglomerates and lumps

Effortlessly break down challenging agglomerates and clumps to ensure smo...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

High-capacity stick pack packaging solution

Enhance your production efficiency by packaging diverse products like powders ...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

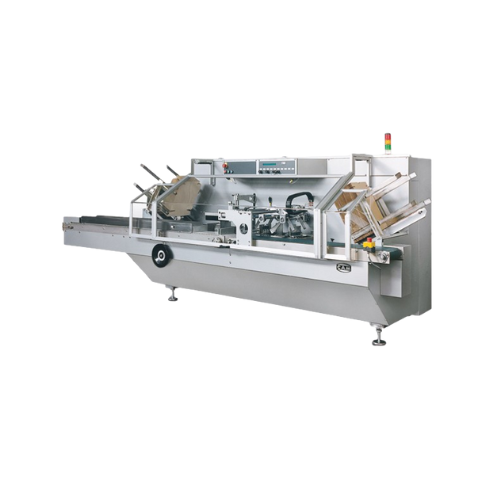

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Corn wet milling plant drying systems

Optimize corn processing efficiency with integrated drying and dewatering systems des...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with pre...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Automatic packaging machine for open-mouth bags

Optimize your packaging line with precision weighing and high-speed baggin...

Vial powder dispensing system

Optimize your aseptic fill process with high-precision powder dispensing that minimizes contam...

Multi-effect water distillator for pharmaceutical applications

Ensure your production line meets stringent regulatory st...

High capacity automatic blister packaging system

Streamline your production line with a high-speed blister packaging syste...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Glass personal blender for nutrient preservation

Experience enhanced flavors and nutrient retention with advanced vacuum b...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

Single-serving blender for quick personal blends

Transform your favorite ingredients into nutritious smoothies, soups, and...

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Table-top mini extruder for precision material processing

Achieve precise control over complex formulations with this fl...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Hybrid laboratory extruders for reproducible scale-up applications

Easily switch between screw diameters to enhance fle...

Flat-bottom twin-screw feeder for precise powder feeding

Achieve precise control in powder dispensing with this flat-bott...

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

High-precision feeding system with load cell and weighing electronics

Achieve unparalleled accuracy in dispensing powde...

Twin screw feeder for bulk material handling

Optimize your bulk material processing with a solution designed for precise f...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Table-top gravimetric feeding solution for precision batches

Achieve high-precision batch filling with integrated gravim...

Gravimetric twin screw feeders for pharma powders

Optimize feeding for challenging materials with dust and water-resistan...

Isolator high containment for granule production

Ensure high-purity production in pharmaceuticals with controlled granulat...

Side feeding device for extruders

Enhance your extrusion process with a side feeding device that gently introduces powders,...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Twin-screw feeder for powders and micro-granules

Ideal for handling poorly flowing powders and granules, this advanced twi...

Volumetric flat-bottom twin-screw feeder for powders

When handling powders prone to clumping, a reliable feeder ensures u...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Twin screw feeder for dosing bulk solids

Ideal for precise bulk solids dosing, this twin screw feeder ensures consistent fl...

Volumetric single-screw feeder for fine dosing

Achieve precise and consistent dosing of fine powders and granules with a c...

Volumetric single-screw feeders for free-flowing products

Achieve precise and continuous feeding of free-flowing powders...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Volumetric single-screw feeder for free-flowing products

Optimize your production line with precise feeding and metering ...

X-ray inspection for tall packages in cans and bottles

Ensure your production line detects foreign objects in tall packag...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Micronization for pharmaceuticals

Achieve ultra-fine particle size reduction for complex materials, essential when precisio...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Volumetric auger for powder weighing and depositing

Ensure precise powder weighing and depositing for consistent product ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Horizontal form-fill-seal systems for pouch packaging

For production lines that demand efficient pouch creation, these hi...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot-scale milling and screening platform

Achieve precise powder consistency and integrity with flexible milling and scre...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Roller compaction for dry granulation in pharmaceuticals

Ensure consistent granule size and density in your product line ...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Industrial powder milling solution

Achieve precise particle size control and improve material flowability with this advance...

Industrial-scale bioreactors for large-scale biomanufacturing

When producing at large volumes, efficient and reliable bi...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Big bag discharger for powder handling

Effortlessly discharge large bags of powdered ingredients with a modular, safe syste...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

Spray dryer for heat-sensitive powders

Ensure high-quality drying of heat-sensitive powders, producing non-caking and non-h...

Spray drying system for nutritional powders

Enhance production efficiency and product quality with a versatile spray dryin...