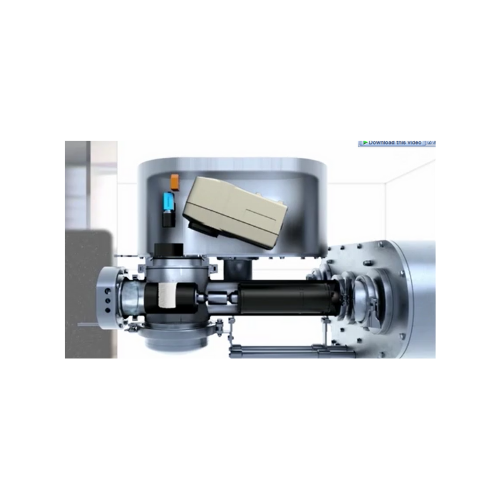

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminants, enhancing production efficiency and product consistency.

Measures and Analyzes Powder Quality In-Line

The POWDEREYE® from GEA is an innovative in-line powder analyzer designed for food, beverage, dairy, and pharmaceutical industries. Positioned after the final drying stage, it continuously measures critical powder properties like residual moisture, dark particles, and density. This system integrates with your spray drying process to ensure optimal product quality by using high-resolution imaging and ATEX-compatible construction with stainless steel. The autosampling feature, controlled via touchscreen or SCADA system, collects and analyzes samples efficiently for consistent monitoring. Capable of detecting out-of-spec conditions, POWDEREYE® supports process optimization and quality supervision, enhancing throughput and reducing production downtime, while meeting industry standards for safety and performance.

Benefits

- Enhances product quality by optimizing moisture content and detecting dark particles in real-time.

- Streamlines operations with automated sampling and analysis, reducing manual intervention and downtime.

- Increases production efficiency by enabling continuous, in-line monitoring and adjustments.

- Ensures operational safety with ATEX-compatible design and immediate out-of-spec alerts.

- Supports process optimization through seamless integration with advanced control systems like GEA OptiPartner.

- Applications

- Food, Beverages, Chemicals, Dairy, Pharmaceuticals

- End products

- Powdered milk, Coffee creamer, Dry spice blends, Infant formula, Vitamin supplements, Instant soup powders, Concentrated fruit powders, Specialty chemicals powders, Protein powder, Cleaning powder chemicals, Drink mixes, Antibiotic powders

- Steps before

- Spray Drying

- Steps after

- Product Packaging, Quality Control, Process Adjustments

- Input ingredients

- product stream, powder during drying process

- Output ingredients

- end product, residual moisture content, dark particles, bulk density, packed density, protein content, fat content

- Market info

- GEA is known for manufacturing industrial engineered-to-order equipment, specializing in technology for food processing, dairy, beverages, and pharmaceuticals, with a reputation for quality, innovation, and sustainable solutions in complex engineering projects.

- Residual moisture measurement

- Continuous

- Dark particles detection

- Hi-res imaging

- Bulk density measurement

- Continuous

- Packed density measurement

- Continuous

- Protein content measurement

- Optional

- Fat content measurement

- Optional

- Material

- Stainless steel

- Anti-static capability

- ATEX-compatible

- Sample size

- 200 mL

- Automation

- SCADA/Touchscreen operated

- Warning system

- Out-of-specification alerts

- Working mechanism

- In-line analysis

- Integrated steps

- Residual moisture, dark particles, density measurement

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Local touchscreen, PLC, SCADA

- Changeover time

- 0 (Continuous Operation)

- Cleaning method

- Manual or CIP

- Corrosive resistance

- Stainless steel, ATEX-compatible

- Cleanability

- Anti-static polypropylene

- Density/particle size

- Measures bulk density, packed density

- ATEX certification

- Yes

- CE marking

- Yes

- Sample cup material

- Stainless steel, Anti-static polypropylene

- Device Material

- Stainless Steel

- Placement Position

- After final drying stage

- Sampling Volume

- 200 mL