Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise bag leveling, secure sealing, and reliable closing for continuous, high-speed operations.

Automates Bag Leveling, Sealing, and Closing

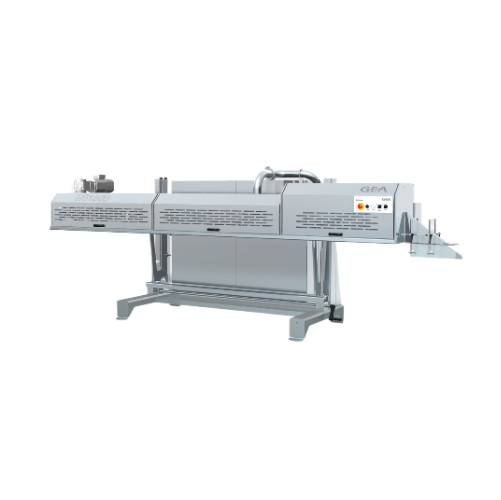

The HS-1000 Leveler/Sealer/Closer from GEA is a cutting-edge solution for automating the bag filling process in industries such as food, dairy, and pharmaceuticals. This machine stands out with its ability to conduct automated leveling, sealing, and closing of bags filled with powdered products, ensuring a reliable and consistent seal without operator intervention. Constructed from high-grade stainless steel, the HS-1000 complies with global hygiene and safety standards, making it particularly suitable for applications involving milk powder, infant formula, protein powder, and more.

The continuous operation system efficiently grips and levels each bag, enhancing uniformity in sealing and operational throughput. Its PLC-controlled interface supports seamless integration with existing production lines, offering options for standalone or fully integrated deployment. Designed to adapt to different bag sizes, the HS-1000 accommodates a range of products with integral polyethylene inner liners, providing options for dust extraction and a bag mouth cleaning system for handling powders prone to adhering during filling.

The HS-1000 includes four automated activity stations, each contributing to a perfectly sealed product: automatic bag leveling, seal cleaning, heat sealing, and optionally, a fold-over closing system. This machine optimizes energy use while maintaining high-speed, continuous operation, ensuring efficiency and reduced labor costs. Supported by GEA’s engineering expertise, custom configurations and engineering support are available to adapt the machine to specific plant requirements, ensuring maximum productivity and minimal downtime.

Benefits

- Eliminates manual handling, reducing labor costs and human error.

- Ensures consistent, airtight sealing for superior product quality.

- Offers seamless integration into existing automated production lines.

- Adapts to various bag sizes, increasing operational flexibility.

- Built to global hygiene standards, ensuring compliance with industry regulations.

- Applications

- Food, Beverages, Detergents, Snacks, Pet food, Nutraceuticals, Spices, Baby food, Powdered products, Sweeteners, Dairy, Pharmaceuticals

- End products

- Spice blends, Malted milk powder, Cocoa powder, Laundry detergent powder, Sugar alternatives, Dry pet food, Infant formula, Vitamin supplements, Electrolyte powders, Milk powder, Baking soda, Protein powder, Instant coffee

- Steps before

- Powder Filling, Bag Pre-stretching

- Steps after

- Packing, Labeling

- Input ingredients

- powdered products, bags with polyethylene inner liner, pre-glued fold-top bags, pre-stretched bags

- Output ingredients

- sealed bags, closed bags, airtight sealed bags, folded-over bag closures

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- PLC-controlled

- Material

- Stainless steel

- Bag type compatibility

- Polyethylene inner liner

- Bag handling

- Fully automated

- Heat sealing stages

- Four activity stations

- Bag size range

- Adjustable

- Dust extraction

- Provision included

- Automation level

- Fully automatic / PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP compatible

- Cleaning method

- Automatic bag seal cleaning

- Changeover time

- Adjustable for a wide range of bag sizes

- Heat sealing method

- Continuous motion Heat Sealer

- Integration capability

- Standalone or fully integrated

- Process steps

- Leveling, sealing, closing

- Cleanability

- Stainless steel construction

- Biological compatibility

- Food-grade stainless steel

- Corrosive resistance (e.g. acids)

- High corrosion resistance

- Abrasion resistance

- Durable against friction

- Density/particle size

- Powdered materials

- Application suitability

- Food, Dairy

- Material

- Stainless Steel

- Machine Type

- Continuous Motion Heat Sealer

- Footprint

- Compact

- Bag Size Adjustability

- Wide Range

- Dust Extraction Provision

- Included

- Control Panel Type

- PLC-controlled

- Type of Sealing System

- Automatic Leveling

- Closing Options

- Fold-over / Sewing / Taping

- Integrated Systems Compatibility

- Standalone or Fully Integrated

- Control panel type

- PLC-controlled

- Integration possibilities

- Standalone or fully integrated versions

- Bag size adaptability

- Adjustable for a wide range of bag sizes