Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality with this multi-tray cooker/conditioner, designed to optimize heating and moisture reduction for diverse oilseeds and plant-based proteins.

Heats and Conditions Oilseeds for Processing

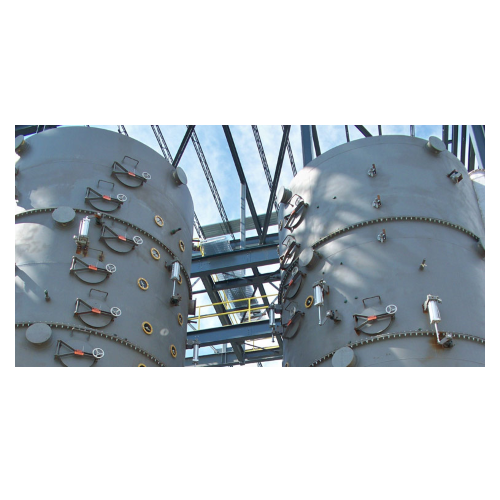

The Cooker / Conditioner from Crown Iron Works efficiently heats and conditions oilseeds, crucial for oil extraction and biofuel production. This vertically stacked system employs steam-heated trays and agitators for uniform cooking, optimizing moisture and heat transfer. It’s ideal for processing soybeans, canola, and hemp seeds, supporting applications like edible oil and biodiesel production.

With flexible design options—including top-fill or bottom-fill configurations—this equipment handles various seed types, offering adjustable seed levels and residence times. Constructed from durable materials, it resists corrosion and ensures long service life.

Capable of integrating seamlessly into continuous production lines, it features automated control options to fine-tune operations. Designed for efficiency, this cooker reduces energy consumption, meeting the needs of modern oilseed processors and biodiesel producers.

Benefits

- Enhances oil yield consistency through precise heating and moisture control.

- Minimizes energy usage with efficient heat transfer and steam utilization.

- Adapts to various seed types, reducing operational disruptions.

- Lowers maintenance frequency with robust, corrosion-resistant construction.

- Seamlessly integrates into existing lines, boosting production efficiency.

- Applications

- Specialty chemicals, Nutraceuticals, Plant-based proteins, Oilseed processing, Food products, Biofuel, Hemp cbd oil extraction, Pharmaceuticals

- End products

- Pea protein, Cooking oils, Sunflower oil, Hemp cbd oil, Personal care products, Edible oils, Salad dressings, Herbal supplements, Protein isolates, Biodiesel, Pharmaceutical-grade oils, Soybean oil, Canola oil, Essential oils

- Steps before

- Grinding, Drying, Cleaning, Sorting

- Steps after

- Pressing, Degumming, Neutralizing, Cooling

- Input ingredients

- oilseeds, hemp, soybean, canola, sunflower, palm, corn

- Output ingredients

- processed meal, oil, hemp oil, plant-based proteins, biodiesel, oleochemicals

- Market info

- Crown Iron Works is renowned for its expertise in designing and manufacturing engineered-to-order equipment for oilseed processing and edible oil extraction, with a strong reputation for innovation, reliability, and delivering customized solutions worldwide.

- Automation

- Manual / Auto dosing

- Capacity

- Dependent on stack diameter and number of trays

- Material compatibility

- Stainless steel available for corrosion resistance

- Residence time

- Easily adjustable

- Temperature control

- Steam-heated trays with direct steam injection

- Size/Configuration

- Vertical stacked cooker

- Working mechanism

- Steam-heated trays, vertical shaft stirrer system

- Integrated steps

- Heating and moisture reduction

- Batch vs continuous operation

- Continuous (with adjustable residence times)

- Automation level

- Manual / Automatic with level control options

- Changeover time

- Quick adjustments for seed variety and capacity

- Cleaning method

- Manual cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel

- Seed Type Compatibility

- Oilseeds

- Footprint

- Vertical Design, Stacked Cooker

- Tray Size

- Variable based on capacity

- Material

- Stainless Steel Available

- Feed/Discharge Method

- Rotary Valves / Mechanical Gates

- Shape

- Vertical Stack

- Stirrer System

- Mounted on Vertical Shaft

- Shell material

- Stainless steel

- Design type

- Top-fill or bottom-fill

- Level control

- Simple chutes, mechanical gates, or rotary valves

- Gate customization

- Mechanical gates with actuators and positioners

- Stirrer design

- Mounted on common vertical shaft