Edible Oil Capping Equipment

Find production technology for capping edible oil bottles, and connect directly with leading machine manufacturers worldwide.

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Which edible oil capping technology do you need?

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

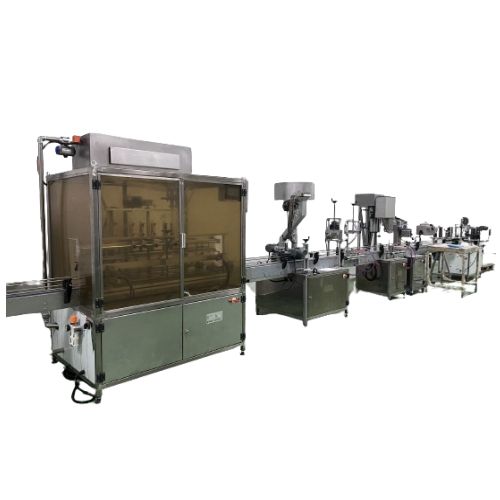

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

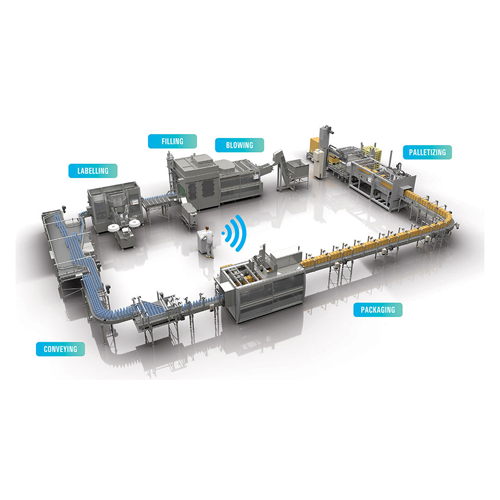

Complete bottling lines for beverages

Achieve seamless integration and high-speed efficiency in your liquid product packagi...

Integrated rotary blowing and filling system for Pet bottles

Optimize your beverage production with an integrated rotary...

Volumetric gravity filler for large Pet bottles

Optimize your production line with a high-speed volumetric gravity filler,...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Manual bag-in-box filling solution

Streamline your liquid packaging with a compact, easy-to-operate filling system that sim...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Roll-on bottle capping solution for aluminum caps

Ensure precise threading and sealing of aluminum caps on diverse bottle...

Manual sealing solution for pre-threaded aluminium screw caps

Achieve precision sealing for your oil-based products with...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Integrated preform production and bottling system for Pet bottles

Achieve seamless production of PET bottles, from pref...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Volumetric filler for Pet bottle beverages

Experience seamless integration into your bottling line with this advanced volu...

Versatile rotary filler-capper for liquid products

Optimize your liquid product production with a versatile solution that...