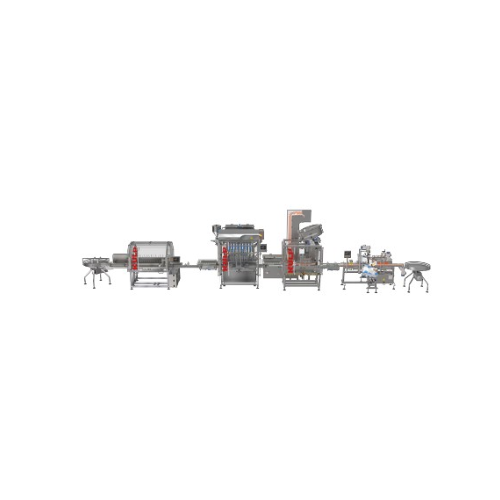

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution processes up to 4,800 packages per hour, integrating seamlessly to ensure precise filling, capping, and labeling of diverse product types, enhancing your production efficiency.

Processes and Packages Liquids and Slurries Efficiently

The High Capacity Filling Line from Kulp Makina is engineered for versatile packaging solutions across diverse industries such as food, cosmetics, and chemicals. This line excels with its synchronized system, incorporating feeding tables, rinsers, filling machines, capping machines, labelers, and collecting tables, ensuring a seamless flow from start to finish. Designed to handle a wide range of liquid and slurry products—ranging from chocolate spreads and sauces to cosmetic creams and industrial chemicals—it provides precision and efficiency with throughputs up to 4800 packages per hour. The system is fully integratable with existing production lines, offering customizable options tailored to specific production needs, and features energy-efficient components to minimize operational costs. Built with robust materials suitable for various applications, it meets stringent industry standards ensuring reliability and longevity. Whether for high-volume food production or delicate cosmetic filling, Kulp Makina offers comprehensive engineering support and optional customization, adapting the equipment to your unique operational requirements.

Benefits

- Enhances operational efficiency with synchronized component interaction, minimizing bottlenecks.

- Flexible for various industries, accommodating a wide range of end-products from food to chemicals.

- Reduces labor costs through automation, ensuring continuous and consistent filling operations.

- Customizable setup supports scalable production needs and specific packaging requirements.

- Optimizes energy usage, lowering operational costs with efficient motor systems.

- Applications

- Veterinary products, Beverages, Biomedical and sanitary products, Household products, Cosmetic products, Food products, Industrial chemicals

- End products

- Sauces, Jam, Gels, Pre-cooked meals, Edible oils, Glaze, Waxes, Engine oil, Pesticides, Peanut butter, Ointments, Pomegranate concentrate, Molasses, Tomato paste, Mashed vegetables, Foundation, Toppings, Glycerin, Glass cleaner, Soups, Cream cheese, Balsamic vinegar, Conditioner, Vaseline, Cream honey, Marmalade, Ayran, Face mask, Yogurt, Syrups, Lotions, Bodywash, Bb cream, Disinfectant, Tapenade, Chocolate spread, Milk, Varnish, Body mask, Hair cream, Hazelnut hash, Mustard, Liquid soap, Fertilizers, American salad, Vinegar, Ketchup, Cosmetic creams, Ink, Labne, Clotted milk, Pepper paste, Mayonnaise, Cheese spread, Cosmetic oils, Shampoo, Honey, Body lotion, Anti-freeze, Hydrogen peroxide, Peelings

- Steps before

- Purification, Drying, Product Preparation, Ingredient Mixing

- Steps after

- Sterilization, Packing, Quality Control, Distribution

- Input ingredients

- jars, bottles, containers, glass jars, caps

- Output ingredients

- filled jars, filled bottles, labeled packages, capped containers, packaged goods

- Market info

- Filling speed

- Up to 4800 packages/hour

- Automation

- Synchronized machines

- Container type

- Jars and bottles

- Filling method

- High capacity and extreme precision

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC-controlled

- Synchronized operation

- Machines work in sequence

- Capacity

- Up to 4800 packages/hour

- Cleaning method

- Air or water rinsing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Low to High

- Container size

- Up to 4800 packages/hour

- Container type

- Jars and Bottles

- Heat Sensitivity

- Yes/No

- Foaming

- Potential Present

- Material type

- Solid / Liquid / Semi-Liquid

- Product Type

- Food, Cosmetics, Chemicals

- Feeding table

- Included

- Discharge method

- Collecting table

- Container type

- Jars and bottles

- Control panel type

- PLC-controlled / HMI

- Integration Possibilities

- Synchronizable machines

- Flexible Configuration

- Feeding table, Rinser, Filling Machine, Capping Machine, Labeler, Collecting Table

- Output Capacity

- Up to 4800 packages/hour

- Filling Line Composition

- Modules vary based on customer needs

- Label Type

- Self-adhesive