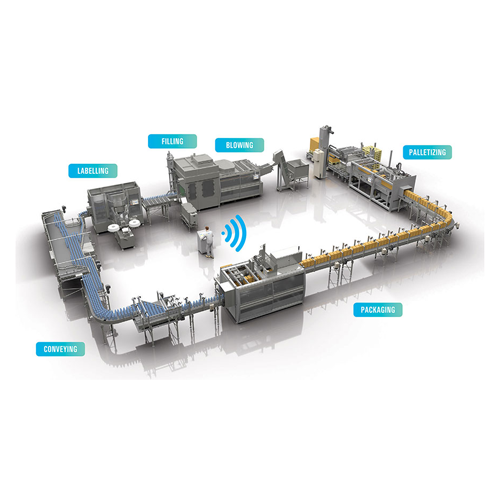

Complete bottling lines for beverages

Achieve seamless integration and high-speed efficiency in your liquid product packaging with advanced automation and IoT-enabled control systems, ensuring precise bottling, filling, and capping processes for optimal production flow.

Streamlines Bottling and Packaging for Liquid Products

The complete bottling and packaging systems by SMI S.p.A. are engineered to enhance efficiency in liquid product processing for the food and beverage industry. These systems integrate advanced Industry 4.0 automation, offering seamless transitions from blowing, filling, and capping to packaging and palletizing. Designed to accommodate flat and carbonated beverages, these systems handle a range of liquid products such as water, soft drinks, and edible oils with a capacity of up to 50,000 bottles per hour. Featuring PLC-controlled operations, these systems ensure high-speed, reliable production with optimized energy usage. Constructed with durable materials suitable for continuous operation, they provide easy maintenance through accessible components and optional CIP systems. Custom configurations ensure tailored solutions for diverse production needs, supported by SMI’s engineering expertise.

Benefits

- Increases production efficiency with continuous, high-speed operation.

- Minimizes energy costs through optimized motor control.

- Ensures product consistency with precise filling and capping processes.

- Simplifies maintenance with accessible, easy-to-clean design.

- Adapts to diverse product lines with customizable configurations.

- Applications

- Carbonated beverages, Water, Milk, Flat beverages, Liquid products, Soft drinks, Edible oil

- End products

- Lemonade, Soda bottles, Sparkling water bottles, Olive oil bottles, Sunflower oil bottles, Orange juice, Cooking oil bottles, Iced tea, Almond milk containers, Still water bottles, Skim milk cartons, Whole milk cartons

- Steps before

- Product Accumulation, Distribution and Conveyance Dynamics Analysis

- Steps after

- Palletizing, Loading onto Conveyor Belts, Product Packing

- Input ingredients

- PET containers, rPET containers, PP containers, flat beverages, carbonated beverages, liquid products, energy resources

- Output ingredients

- packaged PET bottles, packaged rPET bottles, packaged PP bottles, bottled beverages, filled containers, packaged products

- Market info

- SMI Group is known for designing and manufacturing innovative packaging machinery and bottling plants. They provide cutting-edge solutions for ETO equipment, emphasizing flexibility, reliability, and efficiency in serving industries like food, beverage, and consumer goods.

- Capacity

- Up to 50, 000 bottles/hour

- Container Size

- 0.10 to 10 L

- Automation

- Industry 4.0 compliant

- IoT Architecture

- Sophisticated sensors distributed along the line

- Energy Efficiency

- Optimizes energy resources

- Flexibility

- Ensures smooth and constant production flow

- Automation level

- PLC / SCADA / IoT architecture

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Optimized raw materials, workforce, and energy use

- Cleaning method

- CIP for equipment maintenance

- Integrated steps

- Bottling, packaging, and capping

- Working mechanism

- Industry 4.0 technology

- Changeover time

- Efficiency in turn-key systems

- Production flow control

- Smooth and constant production

- Operational flexibility

- High machine yields

- Environmental compatibility

- Improved ecological footprint

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- PET / rPET / PP

- Machine footprint

- Compact design

- Tethered caps

- Included

- Container type

- PET/rPET, PP

- Output capacity

- Up to 50, 000 bottles/hour

- Control panel type

- Integrated with Smart Factory 4.0

- Control panel type

- Industry 4.0 compliant, IoT enabled

- Integration possibilities

- Smart Factory 4.0, IoT architecture

- Automation level

- Highly-automated equipment

- Energy efficiency

- Energy saving technologies

- Production flexibility

- High machine yields, Bespoke solutions

- Raw material optimization

- Optimized employment of raw materials