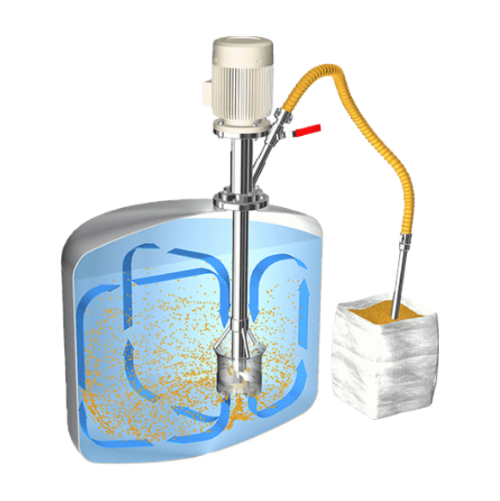

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with precision while ensuring immediate wetting under fluid levels, minimizing contamination and product loss.

Induces and Homogenizes Powders into Liquids

The YSTRAL TDS-Induction Mixer is designed for manufacturers across chemical, paint, coatings, food, pharmaceutical, and cosmetics industries who need efficient integration of powders into liquids. This mixer stands out by inducing powders dust-free below the fluid level, ensuring immediate wetting and homogeneous dispersion. The mixing head generates a vacuum to precisely draw powder, liquids, or gases into the fluid, utilizing the jetstream mixing principle for complete mass transfer. Operable in continuous and automated processes, it supports a range of applications from pigment dispersions to liquid pharmaceuticals. With power options between 5.5 to 25 kW and speeds up to 3,600 min-1, it offers a high-speed solution adaptable for various processing requirements. Constructed with stainless steel 1.4404, it also comes in explosion-resistant designs and includes options for lip or mechanical seals. The YSTRAL TDS-Induction Mixer ensures easy integration with upstream and downstream processes, maintaining product integrity and preventing adhesive buildup on container walls.

Benefits

- Enhances production efficiency with dust-free powder induction.

- Ensures product uniformity through immediate powder wetting and dispersion.

- Reduces operational costs by integrating multiple processes in one machine.

- Minimizes energy usage with optimized motor control for high-speed mixing.

- Offers flexibility with customizable configurations for diverse industrial applications.

- Applications

- Food, Liquid formulations, Inks, Coatings, Cosmetics, Chemical, Powders, Household, Paints, Pharmaceutical

- End products

- Laundry powders, Face creams, Lotions, Liquid pharmaceuticals, Detergents, Shampoos, Protein shakes, Salad dressings, Pigment dispersions, Inkjet inks, Varnishes, Creams

- Steps before

- Powder Handling, Liquid Handling, Vacuum Generation

- Steps after

- Homogenization, Mass Transfer, Product Packaging

- Input ingredients

- powder, liquids, gases

- Output ingredients

- suspension, homogenized mixture, wetting of powders

- Market info

- Ystral is known for its expertise in mixing, dispersing, and powder wetting technologies, providing high-quality engineered-to-order equipment solutions for industries such as chemicals, pharmaceuticals, and food, renowned for innovation, reliability, and efficiency in process optimization.

- Power

- 5.5 – 25 kW

- Speed

- 1.500 / 3.000 min-1, stepless up to 3, 600 min-1 with frequency converter

- Seal

- Lip seal, mechanical seal single or double depending on application condition

- Explosion resistance

- Explosion-resistant design

- Material (diving part)

- Stainless steel 1.4404 (AISI 316 L), special material

- Material (bearing flange)

- Aluminium-coated, stainless steel 1.4404 (AISI 316 L)

- Working mechanism

- Induction and homogenisation

- Integrated steps

- Powder induction, mixing, wetting

- Batch vs. inline operation

- Inline

- Powder handling

- Dust-free induction

- Automation level

- Manual / PLC-controlled

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- 0.1 to 10, 000 cP

- Foaming potential

- Low to High

- Container size

- 50 L to 10, 000 L

- Sensory impact

- Smell, Taste

- Installation method

- Flange or traverse / Lifting frame

- Material of construction

- Stainless steel 1.4404 (AISI 316 L)

- Bearing flange material

- Aluminium-coated, stainless steel 1.4404

- Diving part material

- Stainless steel 1.4404 (AISI 316 L)

- Seal type

- Lip seal, mechanical seal single or double

- Power

- 5.5 – 25 kW

- Speed

- 1, 500 / 3, 000 min-1, stepless up to 3, 600 min-1 with frequency converter

- Seal type

- Lip seal, mechanical seal single or double

- Design options

- Explosion-resistant design

- Material options

- Stainless steel 1.4404 (AISI 316 L), special material

- Mounting options

- Flange or traverse mounting, lifting frame operation