Fine impact mills

Connect directly with world-leading production technology suppliers of innovative fine impact mills

Fine impact mills use a high-speed rotor to pulverize the material as it passes close to a serrated stator. Considerations for choosing the right fine impact mill include the size of the feed material, the desired particle size range, and the hardness of the product.

Which fine impact mills technology do you need?

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

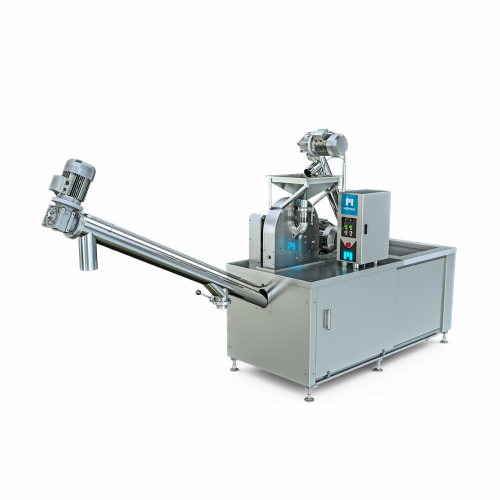

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Gear pelletizer for stable cylindrical pellets

Achieve uniform pellet size and stability in your production line with a lo...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

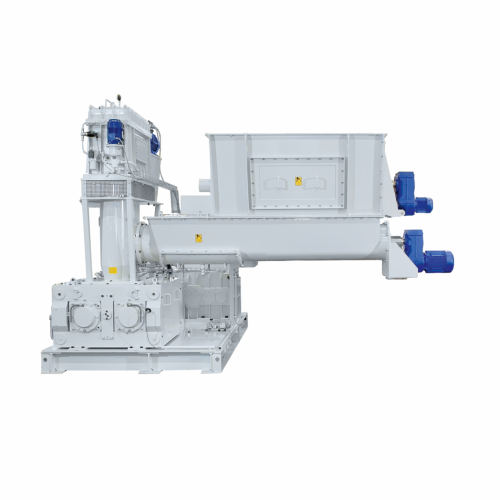

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

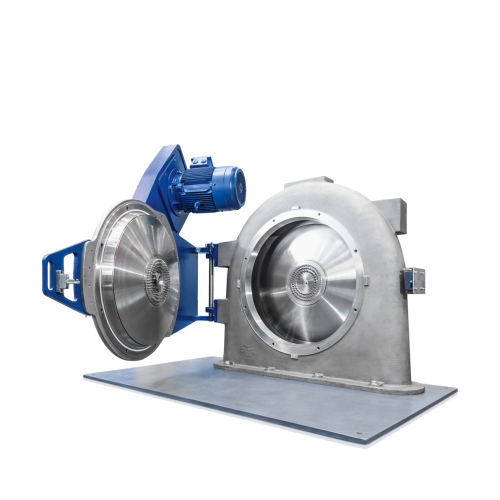

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

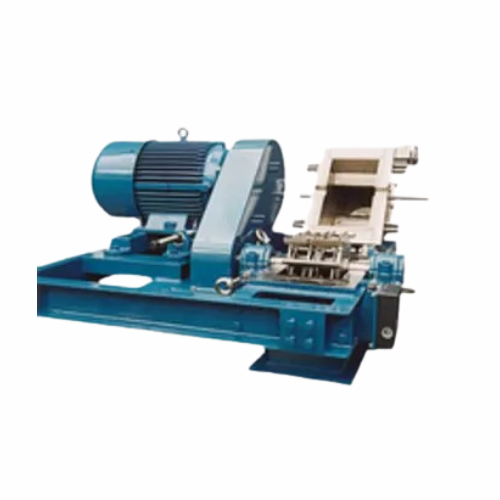

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

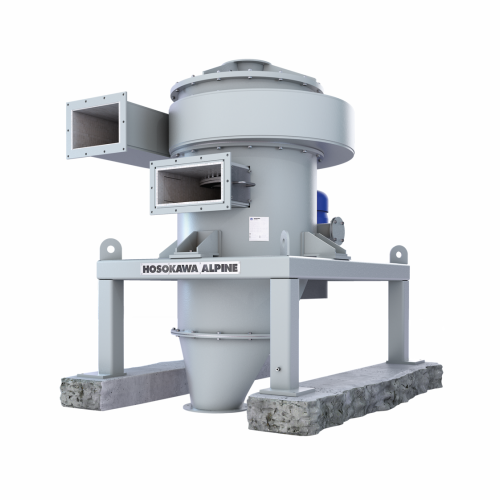

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

High precision air classifier for fine powder processing

Achieve precise particle separation and optimize throughput in y...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ultra-fine grinding with ball mills and agitated media mills

Achieve precision in ultra-fine grinding for demanding mate...

Ultrafine grinding mill for calcium carbonate slurries

Achieve precise particle size distribution in your mineral slurrie...

Dry grinding mill for superfine products

Achieve high fineness in your comminution processes with this advanced dry grindin...

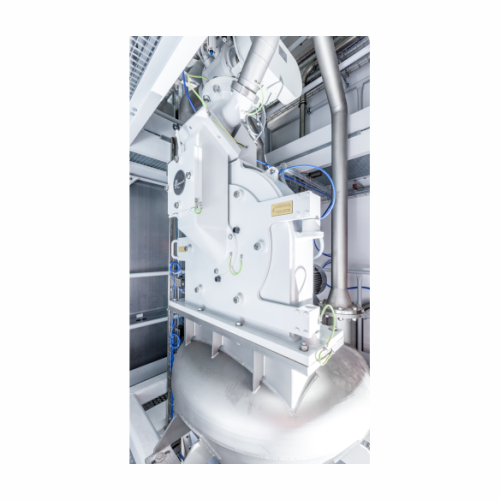

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Classifier mill for ultra-fine grinding and precise particle size control

Achieve consistent ultra-fine particle distr...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Horizontal bead mill for industrial nano grinding

Achieve precision in nano-scale grinding with this advanced bead mill, ...

Chili powder milling machine

Transform raw spices into finely milled powders effortlessly with this high-speed grinding solu...

Impact huller for oats

Hulling technology risks breaking oat grains if the system is not adjustable to fragile materials. Agg...

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...